Wood is one of the oldest materials known to humanity, and it has been used for centuries to make various products, including furniture, flooring, and buildings. Wood is a natural and renewable resource that is easy to work with and has many beneficial properties. However, to create high-quality wood products, it is important to pay close attention to the design process.

This article covers the following:

- Understanding the properties of different types of wood

- Selecting the right wood for your project

- Planning for efficient material use

- Designing with manufacturability in mind

- Choosing appropriate joints for your design

- Accounting for wood movement and expansion

- Balancing aesthetics with functionality

- Incorporating sustainability and eco-friendliness into your design

- Prototyping and testing your design before production

- Communicating effectively with your manufacturing team

- Considering the finishing process and its impact on the final product

- Incorporating appropriate hardware and fasteners

- Addressing common manufacturing challenges in wood design

- Optimizing your design for cost-effectiveness

- Collaborating with other designers and stakeholders in the manufacturing process.

- How can Deskera assist you?

Understanding the Properties of Different Types of Wood

Designing for wood manufacturing requires a thorough understanding of the properties of different types of wood. Each species of wood has its unique characteristics that can affect the design, fabrication, and finishing of the final product. In this blog, we will discuss the various properties of different types of wood that are commonly used in manufacturing and how they can affect the final product.

Hardwoods vs. Softwoods

The first distinction to be made is between hardwoods and softwoods. Hardwoods come from deciduous trees, while softwoods come from coniferous trees. Hardwoods are denser, heavier, and more durable than softwoods.

They are typically used for high-quality furniture, flooring, and cabinetry. Softwoods are less dense, lighter, and less expensive than hardwoods. They are commonly used for construction lumber, paper pulp, and other utilitarian applications.

Grain

The grain of wood refers to the pattern of the fibers that make up the wood. The grain can be straight, curly, wavy, or even irregular. The grain pattern can affect the strength, stability, and appearance of the final product.

Straight grain is the most stable and is often preferred for furniture and cabinetry. Curly and wavy grain can add visual interest and character to a piece but can also make it more difficult to work with.

Texture

The texture of the wood refers to the surface feel of the wood. It can be rough, smooth, or anywhere in between. The texture can affect the way the wood takes stain or finish and can also affect the tactile experience of the final product.

Color

The color of the wood can vary widely between species and can also be affected by the age of the tree and the location where it grew. Some woods, like cherry and mahogany, darken over time as they are exposed to light. The color can affect the overall appearance of the final product and should be taken into account when selecting a species of wood.

Density

The density of the wood refers to how much it weighs per unit volume. Dense woods are harder and more durable than less dense woods. They are also more difficult to work with and may require more specialized tools and techniques.

Moisture Content

The moisture content of the wood refers to the amount of water that is present in the wood. Wood that is too wet or too dry can cause problems during the manufacturing process and can also affect the stability of the final product. Most wood is dried before it is used in manufacturing to ensure that it has a consistent moisture content.

In conclusion, understanding the properties of different types of wood is essential when designing for wood manufacturing. The species of wood selected can affect the strength, stability, and appearance of the final product. By taking into account the properties of the wood, designers can ensure that the final product is both functional and aesthetically pleasing.

Selecting the Right Wood for Your Project

Wood is a versatile and popular material for many manufacturing projects, especially in the furniture and construction industries. However, with so many different types of wood available, it can be challenging to know which wood species to choose for your specific project. In this blog, we'll discuss how to select the right wood for your project, including considerations such as wood species, wood grade, and wood sustainability.

Wood Species

The first consideration when selecting wood for your project is the wood species. Different wood species have varying properties, such as color, texture, strength, and durability. Some wood species are ideal for certain projects, while others may not be suitable.

One popular wood species for manufacturing is oak. Oak is a hardwood that is strong, and durable and has a distinctive grain pattern that gives it a unique appearance. It is commonly used for furniture, flooring, and cabinetry.

Another popular wood species is maple, which is also hardwood. Maple is known for its strength and durability and is commonly used for furniture, flooring, and kitchen utensils.

Pine is a softwood that is widely used in construction projects due to its affordability and availability. Pine is easy to work with and is often used for framing, sheathing, and roofing.

When selecting a wood species for your project, consider the appearance, strength, and durability of the wood, as well as its availability and cost.

Wood Grade

The next consideration when selecting wood for your project is the wood grade. Wood is graded based on its appearance, with higher grades being more aesthetically pleasing and more expensive.

The most common wood grades are Select, #1 Common, and #2 Common. Select is the highest grade, with a uniform color and a few minor imperfections. #1 Common has more pronounced color variations and small knots, while #2 Common has even more pronounced color variations and larger knots.

When selecting a wood grade, consider the appearance of the wood and the level of imperfections that you are willing to tolerate. Keep in mind that higher-grade wood will be more expensive.

Wood Sustainability

Finally, it is important to consider the sustainability of the wood when selecting it for your project. Sustainable wood is harvested in a way that minimizes the impact on the environment and ensures that the forests can regenerate.

Look for wood that has been certified by organizations such as the Forest Stewardship Council (FSC) or the Sustainable Forestry Initiative (SFI). These organizations ensure that the wood has been harvested in a sustainable manner and that the forests are being managed responsibly.

In addition to choosing sustainable wood, you can also reduce waste by using offcuts and scraps in other projects or by recycling them.

Selecting the right wood for your project involves considering the wood species, wood grade, and wood sustainability. Take the time to research the properties and availability of different wood species, and choose a wood grade that meets your aesthetic and budgetary requirements.

Finally, choose sustainable wood to minimize the impact on the environment and ensure that the forests are managed responsibly. By selecting the right wood for your project, you can create a high-quality product that will last for years to come.

Planning for Efficient Material Use

Designing for wood manufacturing involves considering several factors that can affect the efficiency and cost of production. One of the most important of these factors is the efficient use of materials.

Wood is a valuable and limited resource, and optimizing its use is essential for both economic and environmental reasons. In this blog, we will discuss some of the key considerations for planning efficient material use in wood manufacturing.

Design with Material Efficiency in Mind

The first step in planning for efficient material use in wood manufacturing is to design products with material efficiency in mind. This means thinking about how the product can be designed to minimize waste and make the most of the available materials.

For example, using a modular design that allows components to be easily swapped out and reused can significantly reduce waste. Similarly, designing products that use standard-sized sheets of wood or timber can minimize material waste and save costs.

Use Computer-Aided Design (CAD) Software

Using computer-aided design (CAD) software can also help optimize material use in wood manufacturing. CAD software can help designers to visualize products in three dimensions and test different designs and configurations before manufacturing.

This can help to identify and eliminate waste, as well as identify opportunities to use materials more efficiently. For example, the software can help to determine the best way to cut sheets of wood to minimize waste and optimize the use of the available materials.

Optimize Cutting Plans

Another important consideration for efficient material use in wood manufacturing is optimizing cutting plans. This involves determining the best way to cut sheets of wood or timber to minimize waste and maximize yield.

This can be done manually or using software specifically designed for this purpose. By optimizing cutting plans, manufacturers can significantly reduce waste and save costs.

Use Lean Manufacturing Principles

can also be applied to wood manufacturing to optimize material use. Lean manufacturing is a philosophy that emphasizes minimizing waste and maximizing efficiency.

In wood manufacturing, this can involve reducing inventory levels, using just-in-time production methods, and implementing quality control measures to reduce defects and waste. By applying these principles, manufacturers can reduce waste, increase efficiency, and improve product quality.

Consider Sustainable Materials

Finally, when planning for efficient material use in wood manufacturing, it's important to consider sustainable materials. Sustainable materials are those that are produced in a way that minimizes environmental impact and supports the long-term availability of the resource.

Using sustainable materials can help to reduce waste and ensure that wood manufacturing remains a viable industry in the long term. Examples of sustainable materials for wood manufacturing include bamboo, reclaimed wood, and wood harvested from sustainably managed forests.

In conclusion, planning for efficient material use in wood manufacturing is essential for optimizing production, reducing waste, and saving costs. By designing with material efficiency in mind, using CAD software, optimizing cutting plans, applying lean manufacturing principles, and considering sustainable materials, manufacturers can achieve optimal efficiency and profitability while minimizing environmental impact.

Designing with Manufacturability in Mind

Wood has been a popular choice for furniture, architecture, and other structures for centuries. It is a versatile material that is easy to work with and has a timeless appeal. However, designing with wood manufacturability in mind is not always easy. let's explore some key considerations when designing for wood manufacturing.

Material Selection

The first consideration when designing with wood manufacturability in mind is the selection of the right type of wood. The choice of wood will depend on several factors, including the intended use, durability, and aesthetics. Some of the most popular types of wood used in manufacturing include maple, oak, cherry, and walnut.

When selecting the wood, it is essential to consider the grain pattern and texture of the wood. The direction of the grain can affect the strength and stability of the finished product. A skilled woodworker will know how to use the grain to create beautiful and durable designs.

Joinery

Joinery refers to the method of joining two or more pieces of wood together. It is an essential aspect of wood manufacturing, as it affects the strength, stability, and appearance of the finished product. There are several different types of joinery, including dovetail joints, mortise and tenon joints, and tongue and groove joints.

When designing for wood manufacturing, it is essential to consider the type of joinery that will be used. Some joints are more difficult to make than others, and some require specialized tools or equipment. Choosing the right joinery will help ensure that the finished product is strong, stable, and visually appealing.

Dimensional Tolerances

Dimensional tolerances refer to the acceptable range of variation in the size and shape of a product. When designing for wood manufacturing, it is essential to consider the dimensional tolerances that will be required. This will ensure that the finished product is consistent in size and shape and fits together correctly.

Dimensional tolerances are affected by several factors, including the type of wood, the type of joinery used, and the manufacturing process. A skilled woodworker will know how to work with these factors to achieve the desired dimensional tolerances.

Finishing

The finishing process is an essential aspect of wood manufacturing. It involves applying a protective coating to the wood to enhance its appearance and protect it from damage. The type of finish used will depend on the intended use of the product.

When designing for wood manufacturing, it is essential to consider the finishing process. Some finishes are more difficult to apply than others, and some require specialized equipment or techniques. Choosing the right finish will help ensure that the finished product looks beautiful and is protected from damage.

Cost

Finally, when designing for wood manufacturing, it is essential to consider the cost. The cost of wood manufacturing can vary widely depending on the type of wood, the complexity of the design, and the manufacturing process. It is important to consider the cost when designing to ensure that the finished product is affordable and profitable.

Designing with wood manufacturability in mind requires careful consideration of several key factors. Material selection, joinery, dimensional tolerances, finishing, and cost are all important considerations when designing for wood manufacturing. By considering these factors, designers can create beautiful and durable products that are both functional and profitable.

Choosing Appropriate Joints for Your Design

Woodworking is a complex craft that requires a great deal of knowledge and expertise. Among the many aspects of woodworking that require attention, one of the most important is the choice of joints. Joints are the connection points between different pieces of wood, and they are crucial for the strength, stability, and aesthetic appeal of a piece.

Let's explore the different types of joints that are commonly used in wood manufacturing and how to choose the appropriate ones for your design.

Butt Joints

Butt joints are the simplest and most basic type of joint, where the end of one piece of wood is simply glued or nailed to the end of another piece. Butt joints are easy to make and are commonly used for small projects or as temporary joints. However, they are not very strong, and should not be used for heavy loads or high-stress applications.

Lap Joints

Lap joints are similar to butt joints, but they involve overlapping the two pieces of wood instead of simply butting them together. This creates a stronger joint, as there is more surface area for the glue or nails to hold onto. Lap joints are commonly used in framing and cabinet making, and they can be made in a variety of configurations, such as half-lap, full-lap, and cross-lap.

Dado Joints

Dado joints are grooves cut into one piece of wood that is designed to hold another piece of wood. Dado joints are commonly used in shelving, bookcases, and cabinets, as they provide a strong and stable connection between the shelves and the sides. Dado joints can be cut using a variety of tools, including a table saw, a router, or a dado blade.

Rabbet Joints

Rabbet joints are similar to dado joints, but they involve cutting a groove along the edge of one piece of wood instead of in the center. The other piece of wood is then inserted into the groove, creating a strong and stable joint. Rabbet joints are commonly used in cabinet making, as they provide a clean and seamless look.

Mortise-and-Tenon Joints

Mortise-and-tenon joints are one of the strongest and most versatile types of joints in woodworking. They involve cutting a rectangular hole (the mortise) into one piece of wood and a matching projection (the tenon) on the other piece of wood.

The tenon is then inserted into the mortise, creating a strong and stable joint. Mortise-and-tenon joints are commonly used in furniture making, as they provide a strong and durable connection that can withstand heavy loads and stress.

Dovetail Joints

Dovetail joints are a type of mortise-and-tenon joint that is commonly used in furniture making and cabinetry. They involve cutting a series of interlocking pins and tails that fit together tightly, creating a strong and beautiful joint that is both strong and aesthetically pleasing. Dovetail joints require a high degree of skill and precision, but they are well worth the effort for their strength and beauty.

When choosing the appropriate joint for your design, consider the type of project you are making, the materials you are using, and the stresses that the joint will be subjected to.

If you are unsure which joint to use, consult with an experienced woodworker or carpenter to help you make the best choice. With the right joint and a bit of skill and patience, you can create beautiful and durable pieces that will last for years to come.

Accounting for Wood Movement and Expansion

Wood is a popular and versatile material used in many manufacturing processes, including furniture making, cabinetry, and construction. However, it's important to consider the natural properties of wood, including its tendency to expand and contract with changes in temperature and humidity.

Failure to account for wood movement can lead to structural issues, warping, and even cracking. In this blog, we'll explore the concept of wood movement and provide tips on how to design for it in wood manufacturing.

What is Wood Movement?

Wood is a hygroscopic material, which means it can absorb and release moisture from the air. This moisture content affects the size and shape of the wood. When wood absorbs moisture, it expands, and when it loses moisture, it contracts. This natural movement can be a challenge in wood manufacturing, especially when the wood is used in larger structures or pieces.

The amount of wood movement depends on the species of wood, the grain direction, and the moisture content. Some species, like oak and hickory, are more prone to movement than others, such as maple and birch.

Additionally, wood that has been quarter-sawn, where the wood is cut perpendicular to the growth rings, is less likely to move than wood that has been flat-sawn, where the wood is cut parallel to the growth rings.

Designing for Wood Movement

To account for wood movement in wood manufacturing, designers and manufacturers need to consider the following factors:

- Moisture Content: Wood should be dried to the proper moisture content before it's used in manufacturing. This ensures that the wood is stable and won't continue to expand or contract once it's in use. The moisture content of wood used in manufacturing varies depending on the intended use and the climate in which it will be used.

- Joinery: Joinery is the method used to connect pieces of wood. Different joinery methods allow for different amounts of wood movement. For example, using a dovetail joint or a mortise and tenon joint allows for some movement, while using a glue joint or a butt joint does not.

- Grain Orientation: As mentioned earlier, the direction of the grain affects wood movement. Wood that has been flat-sawn will expand and contract more across the grain, while wood that has been quarter-sawn will expand and contract more along the grain. Designers need to take this into account when designing structures or pieces.

- Panel Construction: Wood panels, such as those used in cabinetry or furniture, are particularly prone to movement. To minimize the effects of movement, designers should use techniques like breadboard ends, which allow the panel to move while keeping the overall structure stable.

- Hardware: Hardware, such as screws and nails, can also affect wood movement. Using screws with oversized holes or allowing for a little play in the hardware can help to account for movement.

Designing for wood movement is an essential consideration in wood manufacturing. By accounting for the natural movement of wood, designers, and manufacturers can create structures and pieces that are stable and long-lasting.

Moisture content, joinery, grain orientation, panel construction, and hardware are all factors that need to be considered when designing for wood movement. With careful planning and attention to detail, designers and manufacturers can create beautiful, functional, and durable pieces using this versatile material.

Balancing Aesthetics with Functionality

Wood has been used in furniture manufacturing for centuries due to its durability, versatility, and unique natural beauty. However, when designing and manufacturing wood furniture, it is important to balance aesthetics with functionality to create pieces that not only look beautiful but are also practical and functional. Let's find out how to balance aesthetics with functionality in wood manufacturing and designing.

Understand the Characteristics of Wood

The first step in designing wood manufacturing is to understand the characteristics of wood. Wood is a natural material and can be unpredictable in terms of grain pattern, knots, and color variations.

Understanding these characteristics can help you design furniture that showcases the natural beauty of the wood while also ensuring that it is structurally sound and functional.

Consider the Function of the Furniture

When designing furniture, it is important to consider its function. Furniture is designed to be used, and it should be designed to meet the needs of its intended use.

For example, a chair designed for a dining room will have different design considerations than a lounge chair. Designing furniture that is both aesthetically pleasing and functional requires a balance between form and function.

Choose Appropriate Joinery Techniques

Joinery techniques are an essential part of wood manufacturing. Joinery refers to the way two pieces of wood are joined together to create a strong and stable joint. Choosing appropriate joinery techniques is essential for creating furniture that is both aesthetically pleasing and functional.

For example, if you are designing a table that will be used for heavy-duty tasks, such as a work table, you may want to consider using mortise and tenon joints instead of simple butt joints.

Select Appropriate Wood Finishes

The finish of a piece of wood furniture can greatly affect its overall appearance and durability. Choosing an appropriate finish is important to balance aesthetics with functionality.

For example, if you are designing a piece of furniture that will be exposed to moisture or heavy use, you may want to consider using a waterproof finish, such as polyurethane, to protect the wood.

Consider the Environment

Finally, it is important to consider the environment in which the furniture will be used. For example, if the furniture will be placed in a room with a lot of natural light, you may want to consider using a wood species that will age gracefully and develop a patina over time.

Alternatively, if the furniture is used in a high-traffic area, you may want to consider using a wood species that is more durable and resistant to wear and tear. In conclusion, designing for wood manufacturing requires a balance between aesthetics and functionality.

Understanding the characteristics of wood, considering the function of the furniture, choosing appropriate joinery techniques and finishes, and considering the environment in which the furniture will be used are all essential factors in achieving this balance. By keeping these factors in mind when designing wood furniture, you can create pieces that are not only beautiful but also functional and durable.

Incorporating Sustainability and Eco-Friendliness into your Design

Wood manufacturing and designing is a complex process that involves the extraction, processing, and production of wood products. Sustainability and eco-friendliness have become increasingly important considerations in recent years as the impact of human activities on the environment becomes more apparent.

Incorporating sustainable and eco-friendly practices into wood manufacturing and designing can help reduce the negative impact of these activities on the environment. In this blog, we will explore some of the ways in which sustainability and eco-friendliness can be incorporated into wood manufacturing and designing.

Sourcing Sustainable Wood

The first step in incorporating sustainability into wood manufacturing and designing is to source wood from sustainable forests. Sustainable forests are managed in a way that ensures the health and productivity of the forest ecosystem, while also meeting the needs of the local community.

When sourcing wood, it is important to look for wood that has been certified by organizations such as the Forest Stewardship Council (FSC) or the Programme for the Endorsement of Forest Certification (PEFC). These organizations ensure that wood is sourced from sustainable forests and that the wood is traceable throughout the supply chain.

Using Eco-Friendly Wood Treatments

The next step in incorporating sustainability into wood manufacturing and designing is to use eco-friendly wood treatments. Wood treatments such as paints, varnishes, and stains can contain harmful chemicals that can have a negative impact on the environment.

Using eco-friendly wood treatments can help reduce this impact. Eco-friendly wood treatments are made from natural materials such as linseed oil, beeswax, and plant extracts and do not contain harmful chemicals.

Using Energy-Efficient Manufacturing Processes

Incorporating sustainability into wood manufacturing and designing also involves using energy-efficient manufacturing processes. Energy-efficient manufacturing processes use less energy, reduce greenhouse gas emissions, and can save money on energy costs.

One way to reduce energy consumption is to use equipment that is designed to be energy efficient. Another way is to optimize manufacturing processes to reduce energy waste.

Reducing Waste and Recycling

Reducing waste and recycling are important considerations in any sustainable manufacturing process. In wood manufacturing and designing, it is important to minimize waste by using the most efficient cutting and milling methods possible.

Any waste that is generated should be recycled or repurposed wherever possible. Recycling wood waste can be done by grinding it up and using it for particleboard, MDF, or other products.

Designing for Durability and Longevity

Designing wood products for durability and longevity is an important aspect of sustainability. By designing products that are built to last, we can reduce the need for replacement and therefore reduce waste. This can be achieved by using high-quality materials and designing products that are sturdy and well-built.

Incorporating sustainability and eco-friendliness into wood manufacturing and designing is essential to reducing the negative impact of human activities on the environment.

By sourcing sustainable wood, using eco-friendly wood treatments, using energy-efficient manufacturing processes, reducing waste and recycling, and designing for durability and longevity, we can create wood products that are both beautiful and sustainable.

As consumers, it is important to support companies that prioritize sustainability and eco-friendliness in their manufacturing processes and to make environmentally conscious choices when purchasing wood products.

Prototyping and Testing your Design Before Production

Wood manufacturing is an exciting industry with an extensive history and countless applications. Whether it's a wooden toy, a piece of furniture, or a building material, wood has been used for centuries to create functional and beautiful objects.

However, creating a wood product that is both visually appealing and functional can be challenging. That is why prototyping and testing your design before production is essential in wood manufacturing.

Prototyping is the process of creating a preliminary model of your product that you can test and refine before production. By prototyping, you can identify any design flaws or potential manufacturing issues early on in the process, saving time and money in the long run.

Here are some key steps to prototyping and testing your design before production in wood manufacturing:

Sketch your design

Before you start building your prototype, you should first sketch out your design. This will allow you to visualize the final product and make any necessary changes before you start prototyping.

Create a preliminary model

Once you have your design sketched out, you can create a preliminary model. This can be done with basic materials such as cardboard or foam board. This model will help you identify any potential design issues or areas for improvement.

Refine your design

Using your preliminary model, you can refine your design. You can adjust the dimensions, materials, or construction methods as needed. This is also a good time to consider the functionality and usability of your product.

Create a functional prototype

Once you have refined your design, you can create a functional prototype. This prototype should be made using the same materials and construction methods that will be used in production. This prototype will allow you to test the durability, functionality, and visual appeal of your product.

Test your prototype

With your functional prototype in hand, you can now test your product. This can include testing its structural integrity, its ability to withstand weight, and its overall functionality. This is also a good time to get feedback from potential users or customers.

Refine and repeat

Based on the feedback you receive from testing your prototype, you can refine your design further. This may require creating additional prototypes and testing them until you have a product that meets your design specifications.

By prototyping and testing your design before production, you can identify any design flaws or potential manufacturing issues early on in the process. This can save you time and money in the long run and ensure that your final product meets your design specifications. It also allows you to test the functionality, usability, and durability of your product, ensuring that it will meet the needs of your customers.

Communicating Effectively with your Manufacturing Team

Designing for wood manufacturing is a complex process that requires the coordination and collaboration of many different professionals. One of the most critical aspects of this process is communication.

Effective communication between the design team and the wood manufacturing team is essential to ensure that the final product meets the client's needs, is aesthetically pleasing, and can be manufactured efficiently and within budget.

In this blog, we will discuss some key strategies for communicating effectively with your wood manufacturing team while designing. These strategies include understanding the manufacturing process, creating clear and detailed drawings, considering materials and finishes, and building relationships with the manufacturing team.

Understanding the Manufacturing Process

The first step in communicating effectively with your wood manufacturing team is to understand the manufacturing process. You should familiarize yourself with the equipment and tools used in the manufacturing process, as well as the materials and techniques involved. This will help you design products that can be manufactured efficiently and cost-effectively.

Creating Clear and Detailed Drawings

Clear and detailed drawings are essential for communicating your design ideas to the manufacturing team. These drawings should include all the necessary measurements, specifications, and materials. They should be easy to read and understand and should clearly convey your design intentions.

Consider Materials and Finishes

The choice of materials and finishes can have a significant impact on the final product's appearance and cost. When designing for wood manufacturing, you should consider the availability and cost of different types of wood, as well as the cost and durability of different finishes. This information will help you design products that are both aesthetically pleasing and cost-effective.

Building Relationships with the Manufacturing Team

Finally, building strong relationships with the manufacturing team is crucial for effective communication. This includes visiting the manufacturing facility, talking with the manufacturing team, and collaborating on design ideas.

By building relationships with the manufacturing team, you can gain a better understanding of the manufacturing process, identify potential design challenges, and work together to develop solutions.

Designing for wood manufacturing requires effective communication between the design team and the manufacturing team. By understanding the manufacturing process, creating clear and detailed drawings, considering materials and finishes, and building relationships with the manufacturing team, you can ensure that your designs are efficiently manufactured and meet your client's needs. With these strategies in mind, you can create beautiful, functional, and cost-effective products that meet your client's expectations and stand the test of time.

Consider the Finishing Process and its Impact on the Final Product in Wood Manufacturing.

When it comes to designing for wood manufacturing, there are many factors to consider, including the finishing process and its impact on the final product. Finishing is a crucial step in the manufacturing process that can greatly affect the appearance, durability, and functionality of a wooden product.

Let's explore the importance of considering the finishing process in wood manufacturing and how it can impact the final product.

What is Wood Finishing?

Wood finishing refers to the process of applying a protective coating to a wooden surface to enhance its appearance, protect it from damage, and improve its durability. Finishing can be done using a variety of techniques, including staining, painting, varnishing, and waxing.

Why is Finishing Important in Wood Manufacturing?

Finishing is an important step in the manufacturing process for several reasons. First, it can greatly enhance the appearance of a wooden product. A well-finished product can have a smooth, glossy surface that highlights the natural beauty of the wood grain.

Second, finishing can help protect the wood from damage. By creating a barrier between the wood and the elements, finishing can help prevent moisture damage, scratches, and other forms of wear and tear.

Finally, finishing can improve the durability of a wooden product. A well-finished product is less likely to crack, warp, or split over time, which can increase its lifespan and make it a better investment for the consumer.

How does the Finishing Process Impact the Final Product?

The finishing process can have a significant impact on the final product in wood manufacturing. Here are some of the key factors to consider:

Color and Appearance: The color and appearance of the finished product will depend on the type of finish used. For example, a stain will enhance the natural color of the wood, while a paint or varnish can change the color entirely.

Texture: The texture of the finished product will depend on the type of finish used and the application method. For example, a glossy varnish will have a smooth, shiny texture, while a wax finish will have a more matte, natural texture.

Durability: The durability of the finished product will depend on the type of finish used and the quality of application. A well-applied finish can greatly increase the lifespan of the product, while a poorly applied finish can make it more prone to damage.

Cost: The cost of finishing will depend on the type of finish used and the complexity of the application process. More complex finishes, such as a multi-step staining process, can be more expensive than a simple varnish or paint.

Environmental Impact: The finishing process can have an environmental impact, depending on the type of finish used and the methods of application. For example, some finishes may contain harmful chemicals or produce volatile organic compounds (VOCs) that can be harmful to the environment.

How to Design for the Finishing Process in Wood Manufacturing

Designing for the finishing process in wood manufacturing requires careful consideration of the following factors:

Material Selection: The type of wood used can impact the appearance and durability of the finished product. Some types of wood may be more suitable for certain types of finishes, so it's important to choose the right material for the desired outcome.

Design Considerations: The design of the product can impact the ease of application and the overall appearance of the finished product. For example, a product with intricate details may require more complex finishing techniques than a simpler design.

Finish Selection: The type of finish selected will depend on the desired appearance and level of durability. It's important to choose a finish that is suitable for the intended use of the product.

Application Method: The method of application can impact the overall quality of the finish. Some finishes may require multiple coats or specific application techniques to achieve the desired

Addressing Common Wood Manufacturing Challenges in Wood Designing

Wood manufacturing has been around for centuries and has been used in various applications, from furniture and cabinetry to structural building components. As such, designing for wood manufacturing requires a specific set of considerations to address common challenges that arise during the manufacturing process. In this blog, we will discuss these challenges and how to address them in wood designing.

Wood Selection

The type of wood selected for a specific application is crucial in the manufacturing process. Factors to consider when selecting wood include the wood’s strength, durability, texture, and moisture content.

For instance, softer woods such as pine and cedar may not be as suitable for manufacturing furniture as harder woods such as oak, maple, or cherry. Similarly, wood that is too dry or too wet may cause problems during the manufacturing process, such as splitting or warping. It is, therefore, essential to select the right type of wood that is suitable for the intended application.

Joinery

Joinery is a crucial part of wood manufacturing. It involves connecting two or more pieces of wood to create a solid and robust structure. There are different types of joinery techniques used in wood manufacturing, including mortise and tenon, dovetail, and tongue and groove.

The type of joinery used will depend on the application and the desired aesthetics. It is important to ensure that the joints are strong and durable and will not come apart easily.

Machining and Finishing

Machining and finishing are also essential aspects of wood manufacturing. Machining involves cutting, drilling, and shaping wood into the desired shape while finishing involves sanding, staining, and applying a protective coating to the wood surface.

These processes can pose several challenges, such as chipping or splintering of the wood surface, uneven sanding, or an uneven application of the finish. It is essential to use the appropriate machining and finishing techniques to avoid these challenges.

Assembly

The assembly process is the final step in wood manufacturing. It involves putting all the individual pieces of wood together to form the final product. Assembly can be a challenging process, particularly for complex designs or products that require a high level of precision.

It is essential to plan the assembly process carefully, including the order in which the pieces are put together and the specific tools and techniques needed to ensure a solid and stable structure.

Designing for wood manufacturing requires an understanding of the unique challenges posed by the manufacturing process. By considering the factors discussed in this blog, such as wood selection, joinery, machining and finishing, and assembly, designers can create products that are not only aesthetically pleasing but also strong, durable, and practical.

Proper planning and attention to detail are key to successful wood manufacturing, and designers who take the time to understand these challenges will be better equipped to create products that meet their clients' needs and expectations.

Optimizing your Design for Cost-Effectiveness

Designing for wood manufacturing requires careful consideration of several factors. One of the most important of these is cost-effectiveness. To optimize your design for cost-effectiveness in wood manufacturing, you need to focus on minimizing material waste, maximizing production efficiency, and reducing labor costs. Let's discuss some key strategies for achieving these goals.

Use Standardized Materials

Using standardized materials is one of the most effective ways to reduce material waste and keep costs down. When you use standardized materials, you can take advantage of economies of scale and bulk purchasing discounts. This can help you save money on raw materials and reduce waste by allowing you to use leftover materials on other projects.

Design for Efficiency

Designing for efficiency is another important strategy for cost-effective wood manufacturing. This means designing your products in a way that maximizes production efficiency and minimizes waste.

For example, you can design products that can be cut from a standard sheet of plywood or other wood product, which will help reduce waste and save time during production.

Use Computer-Aided Design (CAD) Software

Computer-Aided Design (CAD) software can be an invaluable tool for optimizing your designs for cost-effectiveness. CAD software allows you to create detailed, accurate models of your products, which can help you identify potential issues before you begin manufacturing. This can help you avoid costly mistakes and ensure that your products are designed for maximum efficiency and cost-effectiveness.

Choose the Right Joinery Techniques

Choosing the right joinery techniques can also help you optimize your designs for cost-effectiveness. Certain joinery techniques, such as dowel joints or biscuit joints, can be faster and more cost-effective than others, such as mortise-and-tenon joints. By selecting the right joinery techniques for your products, you can save time and reduce labor costs.

Streamline Production Processes

Streamlining your production processes is another key strategy for optimizing your designs for cost-effectiveness. This means identifying bottlenecks in your production line and finding ways to eliminate them. For example, you can use automated cutting machines or other equipment to speed up production and reduce labor costs.

Consider Outsourcing

Finally, you may want to consider outsourcing some aspects of your wood manufacturing process to save money. For example, you can outsource cutting or finishing tasks to a third-party manufacturer, which can help you reduce labor costs and free up time to focus on other aspects of your business.

In conclusion, designing for cost-effectiveness in wood manufacturing requires a careful balance between minimizing material waste, maximizing production efficiency, and reducing labor costs. By following the strategies outlined in this blog post, you can optimize your designs for cost-effectiveness and improve your bottom line.

Collaborating with other Designers and Stakeholders in the Manufacturing Process.

Designing for wood manufacturing requires a collaborative effort between designers and stakeholders involved in the process. Let's explore the benefits of collaboration and provide tips on how to effectively collaborate with other designers and stakeholders to ensure a successful wood manufacturing process.

Benefits of Collaboration

Collaboration is essential in wood manufacturing because it helps to ensure that the final product is of high quality, meets design specifications, and is cost-effective. Here are some benefits of collaboration:

- Improved Product Design: Collaboration between designers and stakeholders can help to improve the overall design of the product. By sharing ideas, expertise, and knowledge, designers can create products that are functional, aesthetically pleasing, and meet the needs of the end-users.

- Reduced Costs: Collaboration can also help to reduce costs by identifying potential issues early in the design process. This allows designers to make adjustments before the product is manufactured, reducing the risk of costly errors or redesigns.

- Faster Time-to-Market: Collaboration can help to speed up the time-to-market of the product. By involving stakeholders early in the design process, designers can ensure that the product meets manufacturing requirements and is ready for production.

- Improved Communication: Collaboration can help to improve communication between designers and stakeholders. By working together, designers can gain a better understanding of the manufacturing process, and stakeholders can provide valuable feedback on the design.

Tips for Collaborating with Other Designers and Stakeholders:

- Identify Stakeholders: The first step in collaborating with other designers and stakeholders is to identify who they are. This includes anyone involved in the design and manufacturing process, such as engineers, product managers, and manufacturing personnel.

- Involve Stakeholders Early: It is important to involve stakeholders early in the design process. This allows them to provide feedback on the design and identify any potential issues before the product is manufactured.

- Share Ideas and Knowledge: Collaboration is about sharing ideas and knowledge. Designers should be open to feedback and willing to listen to the ideas of stakeholders. This can help to improve the overall design of the product.

- Define Roles and Responsibilities: It is important to define roles and responsibilities for each stakeholder involved in the process. This helps to ensure that everyone knows what is expected of them and can work together more efficiently.

- Use Collaborative Tools: Collaborative tools can help to streamline the collaboration process. This includes tools such as project management software, communication tools, and file-sharing platforms.

- Regularly Review and Evaluate Progress: It is important to regularly review and evaluate progress to ensure that the project is on track. This can help to identify any issues early in the process and make adjustments as necessary.

Collaborating with other designers and stakeholders is essential in the wood manufacturing process. By working together, designers can create products that are of high quality, meet design specifications, and are cost-effective.

To effectively collaborate, it is important to identify stakeholders, involve them early in the process, share ideas and knowledge, define roles and responsibilities, use collaborative tools, and regularly review and evaluate progress.

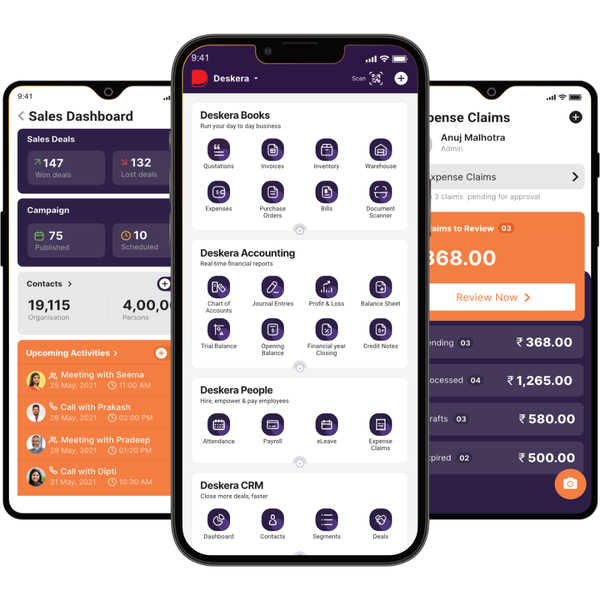

How Can Deskera Assist You?

As a manufacturer, you must keep track of your inventory stock. The condition of your inventory has a direct impact on production planning. It also has a direct impact on people and machinery use and capacity utilization.

Deskera MRP is the one tool that lets you do all of the above. With Deskera, you can:

- Control production schedules

- Compile a Bill of Materials

- Produce thorough reports

- Make your dashboard

Deskera ERP is a complete solution that allows you to manage suppliers and track supply chain activity in real-time. It also allows you to streamline a range of other company functions.

Deskera Books allows you to manage your accounts and finances better. It helps maintain good accounting standards by automating billing, invoicing, and payment processing tasks.

Deskera CRM is a powerful tool that organizes your sales and helps you close deals rapidly. It enables you to perform crucial tasks like lead generation via email and gives you a comprehensive view of your sales funnel.

Deskera People is a straightforward application for centralizing your human resource management activities. Not only does the technology expedite payroll processing, but it also helps you to handle all other operations such as overtime, benefits, bonuses, training programs, and much more.

Key Takeaways:

- Sustainable wood is becoming increasingly popular as people become more conscious of the environment and their impact on it.

- Sustainable wood is a great choice for furniture and home décor, as it helps reduce our impact on the environment.

- When it comes to sustainability, wood is one of the most abundant and renewable resources available to us.

- With the increasing concern about global warming and deforestation, it's important to make sure the wood we buy is sourced from sustainable sources.

- Many companies are now labeling their wood with labels that indicate where the wood was sourced and how it was harvested. Look for labels that say FSC-certified, SFI-certified, or PEFC-certified.

Related Articles: