In the world of plastic manufacturing, there are two primary methods that designers must consider: injection molding and 3D printing. Both processes have their advantages and disadvantages, and the choice between them can greatly affect the final product. Injection molding is a long-established technique that involves injecting melted plastic into a mold, where it cools and solidifies to form the desired shape.

It is fast, accurate, and ideal for the mass production of high-volume products. On the other hand, 3D printing is a more recent innovation that involves creating objects layer by layer from a digital file. It offers greater flexibility and customization, as well as the ability to produce low volumes of products quickly and easily.

In this article, we will compare and contrast these two methods of plastic manufacturing and discuss the design considerations that are unique to each process.

By understanding the differences between injection molding and 3D printing, designers can make informed decisions and create products that are optimized for their chosen manufacturing method.

- Designing for Plastic Manufacturing

- Injection Molding

- 3d Printing

- Comparing Injection Molding and 3d Printing

- How can MRP and ERP Help Plastic Manufacturers?

- How can Deskera Help You?

- Key Takeaways

- Related Articles

Designing for Plastic Manufacturing

Designing for plastic manufacturing involves creating a product design that can be efficiently and effectively produced using plastic manufacturing techniques. This process requires consideration of factors such as the type of plastic material to be used, the manufacturing method, and the design's ability to be molded or printed.

Designers must consider aspects such as the required tolerances, draft angles, wall thickness, and part geometry to ensure that the product can be manufactured to the desired specifications. By designing for plastic manufacturing, designers can create products that meet quality standards, are produced efficiently, and are cost-effective to manufacture.

It also helps to ensure that the final product is aesthetically pleasing, functional, and safe for its intended use. Ultimately, designing for plastic manufacturing is essential for creating products that meet customer needs while also meeting production requirements and minimizing waste.

Injection Molding

Injection molding is a manufacturing process used to create plastic parts or products in large quantities. It involves melting plastic pellets in a heated barrel, then injecting the molten plastic under high pressure into a mold cavity. The plastic then cools and solidifies to form the desired shape of the product. Injection molding is highly automated and can produce complex, intricate shapes with high accuracy and consistency.

It is commonly used to manufacture a wide variety of plastic products, from small parts to large components, including toys, medical equipment, automotive parts, and more. Injection molding has several advantages over other plastic manufacturing methods, including high production speed, low labor costs, and the ability to produce parts with tight tolerances and excellent surface finishes.

Additionally, it is highly repeatable, allowing for the consistent production of identical parts. However, injection molding can be expensive to set up initially and may require specialized tooling and equipment.

Advantages of Injection Molding

Injection molding offers several advantages over other plastic manufacturing methods, including:

- Speed: Injection molding is a fast and efficient process that can produce large quantities of parts quickly. This makes it an ideal manufacturing process for high-volume production runs.

- Accuracy: Injection molding produces parts with high accuracy and consistency. The molds in injection molding are designed to produce parts with tight tolerances, ensuring that each part is produced to the exact specifications required.

- Mass production: Injection molding is an efficient process for mass-producing identical parts. Once the mold is set up, the process can be automated, allowing for the production of thousands or even millions of parts with minimal human intervention.

- Material versatility: Injection molding can be used with a wide range of plastic materials. This includes thermoplastics, thermosets, and elastomers. This allows for a high degree of flexibility in choosing the right material for each application.

- Surface finish: Injection molding can produce parts with excellent surface finishes, making it ideal for parts that require a smooth or polished surface.

Overall, injection molding is a highly versatile and efficient manufacturing process that is ideal for producing high-quality, precision parts in large quantities.

Examples of Products Commonly Made Through Injection Molding

Injection molding is a popularly used manufacturing process that can produce a vast range of plastic products. Some of the most common products made through injection molding include:

- Automotive parts: This area implements injection molding to produce various automotive parts, such as dashboards, interior trims, door panels, and more.

- Consumer goods: Many consumer goods, such as kitchenware, toys, and electronic casings, are made using injection molding.

- Medical equipment: Injection molding is ideal for producing medical equipment such as syringes, medical tubing, and other devices that require high precision and consistency.

- Packaging: Injection molding is used to produce packaging products, such as bottle caps, containers, and lids.

- Electrical components: Electrical components such as connectors, switches, and housings are often produced through injection molding.

- Building and construction materials: Injection molding is used to produce a variety of building and construction materials, including PVC pipes, fittings, and other components.

- Aerospace and defense: Many aerospace and defense components are made using injection molding, including housing for electronics, sensors, and communication devices.

These are some examples of products commonly made through injection molding. The versatility and flexibility of the injection molding process make it a preferred choice for manufacturing a wide range of plastic products.

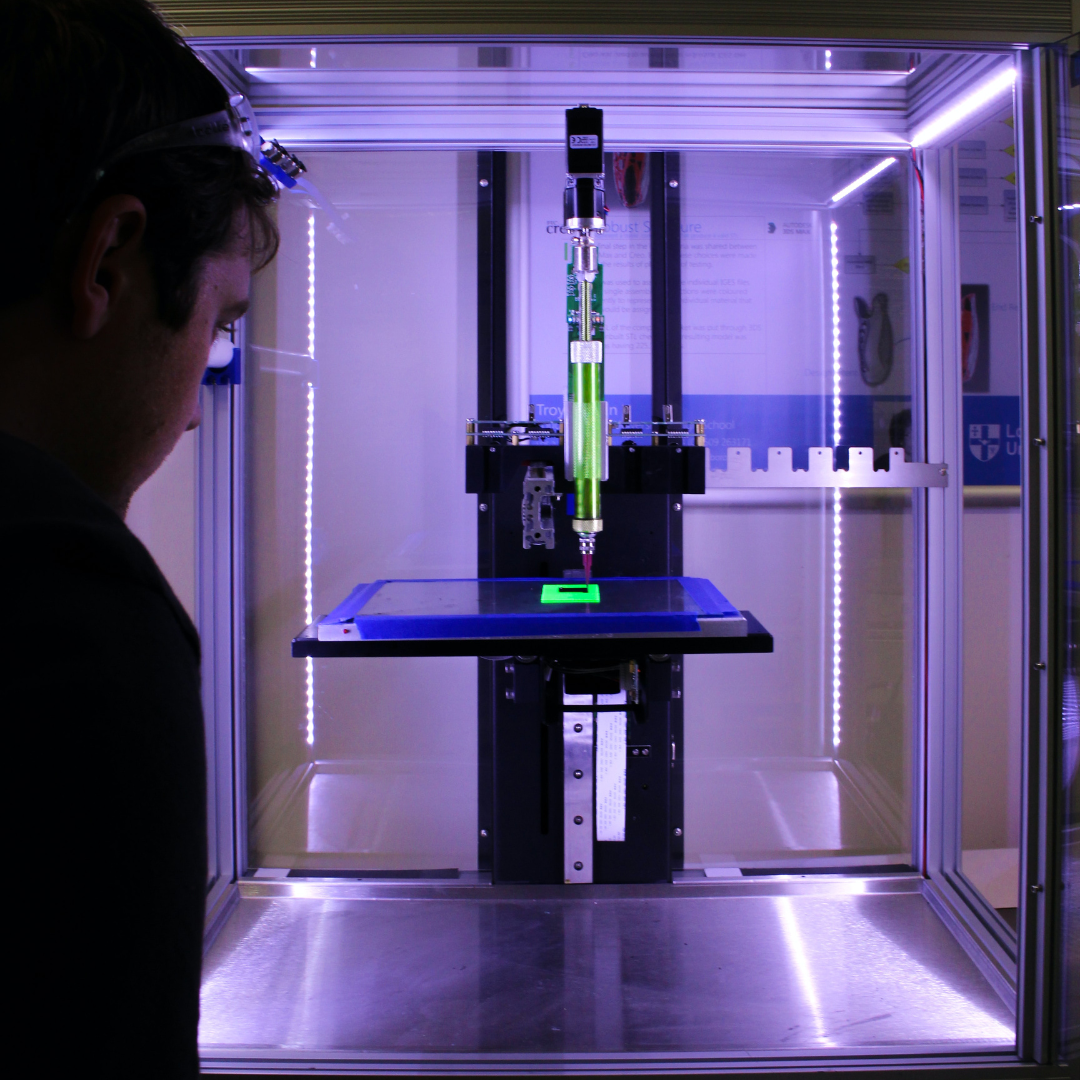

3d Printing

3D printing is an increasingly popular technology for plastic manufacturing because it offers several advantages over traditional manufacturing methods. Specifically, 3D printing allows for the creation of complex, customized, and low-volume plastic products with high precision and accuracy.

In plastic manufacturing, 3D printing can be used to create prototypes of plastic parts or products quickly and cost-effectively. Designers can quickly produce multiple iterations of a product design, allowing them to test and refine the design before committing to costly tooling for mass production.

3D printing is also ideal for producing low-volume, specialized plastic products, such as custom medical implants or dental aligners, that require a high degree of precision and customization. These products can be produced quickly and at a lower cost compared to traditional manufacturing methods.

Additionally, 3D printing can produce plastic parts with intricate geometries and fine details that would be difficult or impossible to produce with traditional injection molding techniques. This makes it an ideal technology for creating one-of-a-kind or highly customized plastic products.

Overall, 3D printing is a powerful tool in plastic manufacturing that allows designers and manufacturers to create highly customized, intricate plastic products quickly and cost-effectively.

Advantages of Injection Molding

A widely used plastic manufacturing process, injection molding offers several advantages, including:

- High efficiency: Injection molding is a highly efficient process that can produce large quantities of identical parts quickly and accurately. This makes it ideal for mass production runs.

- Precision and accuracy: Injection molding produces parts with high precision and accuracy. These molds used in the process are designed to produce parts with tight tolerances, ensuring that each part is produced to the exact specifications required.

- Material versatility: Injection molding can be used with a wide range of plastic materials. This allows for a high degree of flexibility in choosing the right material for each application.

- Minimal waste: Injection molding produces very little waste material, making it a more environmentally friendly process than other manufacturing methods.

- Low labor costs: Once the mold is set up, the injection molding process can be largely automated, reducing the need for manual labor and minimizing production costs.

- Consistent quality: Injection molding produces parts with consistent quality, ensuring that each part is identical to the others in the production run.

Injection molding is a highly efficient, precise, and versatile plastic manufacturing process that offers several advantages over other methods. It is widely used in a variety of industries, including automotive, medical, and consumer goods manufacturing.

Examples of Products Commonly Made Through Injection Molding

Injection molding is a widely used manufacturing process that can produce a vast range of plastic products. Some of the most common products made through injection molding include:

- Automotive parts: Injection molding is commonly used to produce various automotive parts, such as dashboards, interior trims, door panels, and more.

- Consumer goods: Many consumer goods, such as kitchenware, toys, and electronic casings, are made using injection molding.

- Medical equipment: Injection molding is ideal for producing medical equipment such as syringes, medical tubing, and other devices that require high precision and consistency.

- Packaging: Injection molding is used to produce packaging products, such as bottle caps, containers, and lids.

- Electrical components: Electrical components such as connectors, switches, and housings are often produced through injection molding.

- Building and construction materials: Injection molding is used to produce a variety of building and construction materials, including PVC pipes, fittings, and other components.

- Aerospace and defense: Many aerospace and defense components are made using injection molding, including housing for electronics, sensors, and communication devices.

These are just a few examples of products commonly made through injection molding. The versatility and flexibility of the injection molding process make it a preferred choice for manufacturing a wide range of plastic products.

Comparing Injection Molding and 3d Printing

Injection molding and 3D printing are two different plastic manufacturing processes that have their own unique advantages and disadvantages. Here are some key differences between the two processes:

- Cost: Injection molding is typically more cost-effective for large production runs, while 3D printing is better suited for low-volume production and prototyping.

- Speed: Injection molding is a faster process, producing large quantities of identical parts in a short amount of time, while 3D printing is a slower process that produces one part at a time.

- Complexity: 3D printing is better suited for creating complex, intricate shapes and designs, while injection molding is better suited for producing simple, geometric shapes.

- Material selection: Injection molding offers a wider selection of materials, including high-performance materials such as polycarbonate, nylon, and acetal, while 3D printing is limited to a smaller range of materials, typically plastics, and resins.

- Surface finish: Injection molding produces parts with a smooth, polished finish, while 3D printing produces parts with a slightly rougher surface finish.

- Tolerance and accuracy: Injection molding produces parts with tighter tolerances and higher accuracy, while 3D printing can have slight variations in accuracy and tolerances.

Ultimately, the choice between injection molding and 3D printing depends on the specific requirements of the project, including the required volume, complexity of the design, material selection, and other factors. Both processes have their own unique advantages and disadvantages and can be used effectively in a wide range of plastic manufacturing applications.

How can MRP and ERP Help Plastic Manufacturing

MRP (Material Requirements Planning) and ERP (Enterprise Resource Planning) systems can help plastic manufacturing in several ways:

- Material planning and inventory management: MRP and ERP systems can help with inventory management by providing real-time data on raw materials, finished goods, and work in progress. This information can be used to optimize inventory levels, reduce waste, and avoid stockouts.

- Production scheduling: MRP and ERP systems can help with production scheduling by providing visibility into the availability of materials and resources. This can help ensure that production is scheduled efficiently and that resources are allocated appropriately.

- Quality control: MRP and ERP systems can help with quality control by providing data on the quality of raw materials, work in progress, and finished goods. This information can be used to identify quality issues early on and take corrective action.

- Cost control: Both systems can help with cost control by providing visibility into costs associated with raw materials, labor, and overhead. This information can be used to identify areas where costs can be reduced and to track the impact of cost-saving measures.

- Customer service: MRP and ERP systems can help with customer service by providing visibility into order status, delivery dates, and inventory levels. This can help ensure that customers receive accurate and timely information about their orders.

MRP and ERP systems can help plastic manufacturers improve efficiency, reduce costs, and improve customer service, which can help them remain competitive in a challenging market.

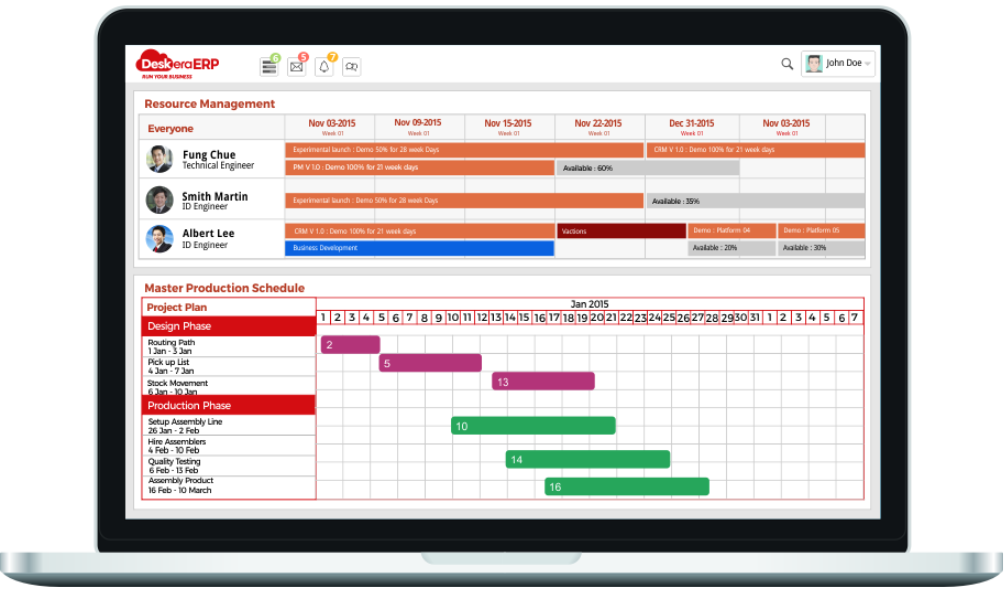

How can Deskera Help You?

Deskera ERP and MRP systems help you to keep your business units organized. The system's primary functions are as follows:

- Keep track of your raw materials and final items inventories

- Control production schedules and routings

- Keep a bill of materials

- Produce thorough reports

- Make your own dashboards

Deskera's integrated financial planning tools enable investors to better plan and track their investments. It can assist investors in making faster and more accurate decisions.

Deskera Books allows you to better manage your accounts and finances. Maintain good accounting practices by automating tasks like billing, invoicing, and payment processing.

Deskera CRM is a powerful solution that manages your sales and helps you close deals quickly. It not only enables you to perform critical tasks like lead generation via email, but it also gives you a comprehensive view of your sales funnel.

Deskera People is a straightforward tool for centralizing your human resource management functions.

Key Takeaways

- Injection molding is a high-volume manufacturing process that can produce large quantities of parts quickly, while 3D printing is a low-volume process that is better suited for prototyping and small-scale production runs.

- Injection molding requires tooling to be created before production can begin, which can be expensive and time-consuming.

- 3D printing does not require tooling, making it more cost-effective for small-scale production runs and prototyping.

- Injection molding can produce parts with more consistent and precise dimensions, while 3D printing may have slight variations due to the layer-by-layer printing process.

- Injection molding is better suited for producing complex parts with tight tolerances, while 3D printing is better suited for producing geometrically simple parts with looser tolerances.

- Injection molding is better suited for producing parts with a smooth surface finish, while 3D printing may require additional post-processing steps to achieve a smooth surface finish.

- Injection molding is better suited for producing parts with high mechanical strength, while 3D printing materials may have lower strength and durability.

- Injection molding can use a wider range of plastic materials than 3D printing, including materials that are not compatible with 3D printing processes.

- Injection molding is better suited for producing large parts, while 3D printing has size limitations.

- Designing for injection molding requires careful consideration of factors such as draft angles, wall thickness, and gate placement while designing for 3D printing requires consideration of factors such as layer height, infill density, and support structures.

- The choice between injection molding and 3D printing depends on factors such as production volume, part complexity, surface finish requirements, material selection, and cost considerations.

Related Articles