According to a recent National Retail Federation (NRF) study, US retailers lose billions of dollars yearly due to overstocks, stockouts, and other inventory-related issues. This equates to billions of dollars in lost revenue each year.

Effective demand planning is a necessary process that helps companies mitigate these losses by accurately predicting customer demand for their products and services.

By clearly understanding what customers want and when they want it, companies can make informed decisions about inventory levels and avoid the costs associated with overstock and stockouts.

In this article, we will discuss the importance of demand planning for better inventory management, including the benefits, best practices, and challenges involved. By understanding the key concepts and techniques involved in demand planning, companies can develop more effective strategies for managing their inventory and meeting the needs of their customers.

Here’s what we shall cover in this post:

- What is Demand Planning?

- Optimize With Inventory on Demand

- Steps for Developing a Demand Planning Strategy

- Demand Planning Methods

- What does a Demand Planner Do?

- Demand Planning Best Practices for Better Inventory Management

- Challenges in Demand Planning to Manage Inventory

- Conclusion

- Key Takeaways

What is Demand Planning?

Demand planning is the process of predicting the future demand for a product or service based on various factors such as historical sales, market trends, and customer behavior.

- It is an essential aspect of inventory management that helps businesses make informed decisions about how much product to manufacture or purchase when to do it, and how to distribute it.

- Demand planning aims to align the supply of goods with customer demand to ensure enough inventory to meet customer needs while reducing excess stock.

- Accurate demand planning is critical for businesses because it helps reduce the risk of stock shortages and overproduction.

- By predicting demand, companies can ensure that they have the right amount of inventory on hand to meet customer needs, which can improve customer satisfaction and increase sales.

On the other hand, overproduction can result in excess inventory and wasted resources, leading to increased costs and reduced profits.

Optimize With Inventory on Demand

Inventory on demand is a management method that helps businesses optimize their inventory levels by keeping only the amount of stock needed to meet current customer demand.

This approach allows companies to reduce the cost of excess inventory and improve overall inventory management.

- Supports Just-In-Time (JIT) Inventory Management: Inventory on demand supports Just-In-Time (JIT) inventory management, which is an approach to inventory management that involves keeping only the minimum amount of inventory needed to meet customer demand. JIT helps reduce inventory carrying costs and improves supply chain efficiency.

- Supports Sales and Marketing Efforts: Inventory on demand provides businesses with the information they need to make informed decisions about production, purchasing, and distribution, supporting sales and marketing efforts.

- Increases Visibility and Control: Inventory on demand helps businesses gain visibility into their inventory levels and improve control over their inventory management processes, reducing the risk of stock shortages and improving overall supply chain efficiency.

- Enhances Responsiveness: Inventory on demand helps businesses respond more quickly to changes in customer demand, ensuring that they have the right products in stock when customers want them.

- Supports Inventory Optimization: Inventory on demand supports inventory optimization, which involves balancing inventory costs and stock shortage costs to find the optimal inventory level. Inventory optimization helps businesses improve their overall inventory management and increase profits.

Steps for Developing a Demand Planning Strategy

Gather Data

The first step in developing a demand planning strategy is to gather data. This data can include historical sales data, market research, and information about the competitive landscape. This data will provide a foundation for making informed decisions about production, purchasing, and distribution.

Analyze Data

The next step is to analyze the data that has been gathered. This analysis should focus on identifying trends, patterns, and other information that can inform the demand planning process.

For example, research may reveal that sales of a particular product are highest during a specific time of year or that a new competitor has entered the market.

Develop a Demand Forecast

The next step is to develop a demand forecast based on the gathered and analyzed data. This forecast should be based on the best available information and consider factors such as seasonality, trends, and market conditions.

Determine Inventory Levels

The next step is determining the appropriate inventory levels for each product based on the demand forecast. This will involve balancing the costs of inventory and the costs of stock shortages to find the optimal inventory level.

Implement Inventory Management Processes

Once the appropriate inventory levels have been determined, the next step is implementing inventory management processes. This may involve using software or other tools to track inventory levels, setting up processes for ordering new inventory, and establishing procedures for monitoring and adjusting inventory levels as needed.

Evaluate the Demand Planning Strategy

The final step is to evaluate the demand planning strategy on an ongoing basis. This evaluation should focus on determining the accuracy of the demand forecast, the effectiveness of the inventory management processes, and the overall impact on customer satisfaction, profits, and supply chain efficiency.

Continuously Improve

It is essential to improve the demand planning strategy over time continuously. This can involve making changes based on the evaluation results, incorporating new data and information, and adjusting the approach as needed.

Demand Planning Methods

Moving Average Method

The moving average method is a simple method that uses a moving average of past demand to predict future demand. This method can be used to smooth out fluctuations in demand, making it a helpful approach for products with moderate variability in demand.

Weighted Moving Average Method

The weighted moving average method is similar to the moving average method but assigns greater weight to more recent data. This method can be used to reflect changes in demand that have occurred more recently, making it a helpful approach for products with rapidly changing demand.

Exponential Smoothing Method

The exponential smoothing method is a more sophisticated method that uses an exponential formula to smooth out fluctuations in demand. This method can be used to adjust the forecast based on past demand and can be helpful for products with moderate to high variability in demand.

Trend Projection Method

The trend projection method is a method that uses historical data to identify trends in demand and then projects these trends into the future. This method can predict demand for products experiencing significant growth or decline and can be helpful for products with high variability in demand.

Regression Analysis Method

The regression analysis method is a statistical method that uses historical data to identify relationships between demand and other factors, such as price or advertising. This method can be used to identify trends and patterns in demand and can be helpful for products with moderate to high variability in demand.

Causal Modeling Method

The causal modeling method is a method that uses historical data and information about other factors, such as promotions or events, to predict demand. This method can be used to identify the impact of these factors on demand and can be helpful for products with moderate to high variability in demand.

Judgmental Method

The judgmental method is a method that relies on the expertise and judgment of the demand planner. This method can be used to incorporate subjective factors, such as market intelligence or personal experience, into the demand planning process.

What does a Demand Planner Do?

A demand planner is a professional responsible for forecasting and planning the demand for products and services. The demand planner is critical in ensuring that a company's inventory levels are aligned with customer demand, helping minimize costs, optimize sales, and improve customer satisfaction.

Here are the key responsibilities of a demand planner:

- Forecasting demand: A demand planner is responsible for forecasting the demand for products and services, considering factors such as sales trends, market conditions, and customer behavior.

- Developing demand plans: Based on the demand forecast, the demand planner develops a demand plan that outlines the expected demand for each product over a specific time.

- Collaborating with sales and marketing: The demand planner works closely with sales and marketing teams to ensure that demand plans are aligned with company goals and objectives.

- Managing inventory levels: The demand planner ensures that inventory levels are maintained at optimal levels, considering factors such as lead times, safety stock, and capacity constraints.

- Monitoring and analyzing demand trends: The demand planner regularly monitors and analyzes demand trends to identify opportunities for improvement and make necessary adjustments to the demand plan.

- Managing the supply chain: The demand planner works closely with suppliers and logistics teams to ensure that the supply chain is aligned with the demand plan and that product deliveries are on time and at the correct cost.

- Communicating with stakeholders: The demand planner communicates regularly with stakeholders, including management, sales and marketing teams, suppliers, and logistics teams, to ensure that everyone knows the demand plan and any changes that may impact it.

- Utilizing technology: The demand planner uses technology and software, such as demand planning software, to automate and streamline the demand planning process.

Demand Planning Best Practices for Better Inventory Management

Effective demand planning can help minimize costs, improve customer satisfaction, and optimize sales. Here are some best practices for demand planning:

- Collaborate with cross-functional teams: Collaboration between sales, marketing, and supply chain teams is essential for effective demand planning. The demand planner should work closely with these teams to gather relevant data, understand market trends, and develop a demand plan aligned with company goals and objectives.

- Utilize technology: Technology and software, such as demand planning software, can automate and streamline the demand planning process. The demand planner should be familiar with the latest technology and tools and use them to gather and analyze data, develop demand plans, and monitor progress.

- Regularly review and update the demand plan: The demand plan should be reviewed and updated regularly to reflect changes in market conditions, customer behavior, and company goals. The demand planner should be proactive in identifying trends and making necessary adjustments to the demand plan.

- Consider historical data and trends: Historical data and trends are a valuable source of information for demand planning. The demand planner should consider this data when developing the demand plan, considering factors such as seasonality, promotions, and other events that may impact demand.

- Incorporate forecasting methods: Several forecasting methods can be used for demand planning, each with its own advantages and limitations. The demand planner should know these methods and choose the best approach for the analyzed product and market.

Challenges in Demand Planning to Manage Inventory

Demand planning is essential for inventory management and ensuring that products and services are available to customers when and where they are needed.

However, demand planning also comes with its own set of challenges that can impact the accuracy of the demand plan and lead to inefficiencies in the supply chain. Here are some of the challenges in demand planning:

- Uncertainty and volatility in demand: Changes in market conditions, customer behavior, and economic conditions can create uncertainty and volatility in demand. This can make it challenging to develop an accurate demand plan and manage inventory levels effectively.

- Limited data and resources: The demand planner may have limited data and resources available to develop the demand plan. This can make it difficult to gather relevant information, analyze trends, and make informed decisions.

- Integration with other processes and systems: Demand planning should be integrated with other processes and systems within the company, including sales and marketing, supply chain, and logistics. However, this can be challenging if different departments use different systems and processes.

- Limited visibility into demand signals: The demand planner may have limited visibility into demand signals, such as customer orders and shipments, which can impact the accuracy of the demand plan.

- Inaccurate forecasting: Inaccurate forecasting can lead to incorrect demand plans and impact inventory levels. This can result in stockouts, overstocks, and inefficient use of resources.

- Resistance to change: Companies may resist change, making it challenging to implement new demand planning processes or technologies. This can limit the ability to improve demand planning accuracy and efficiency.

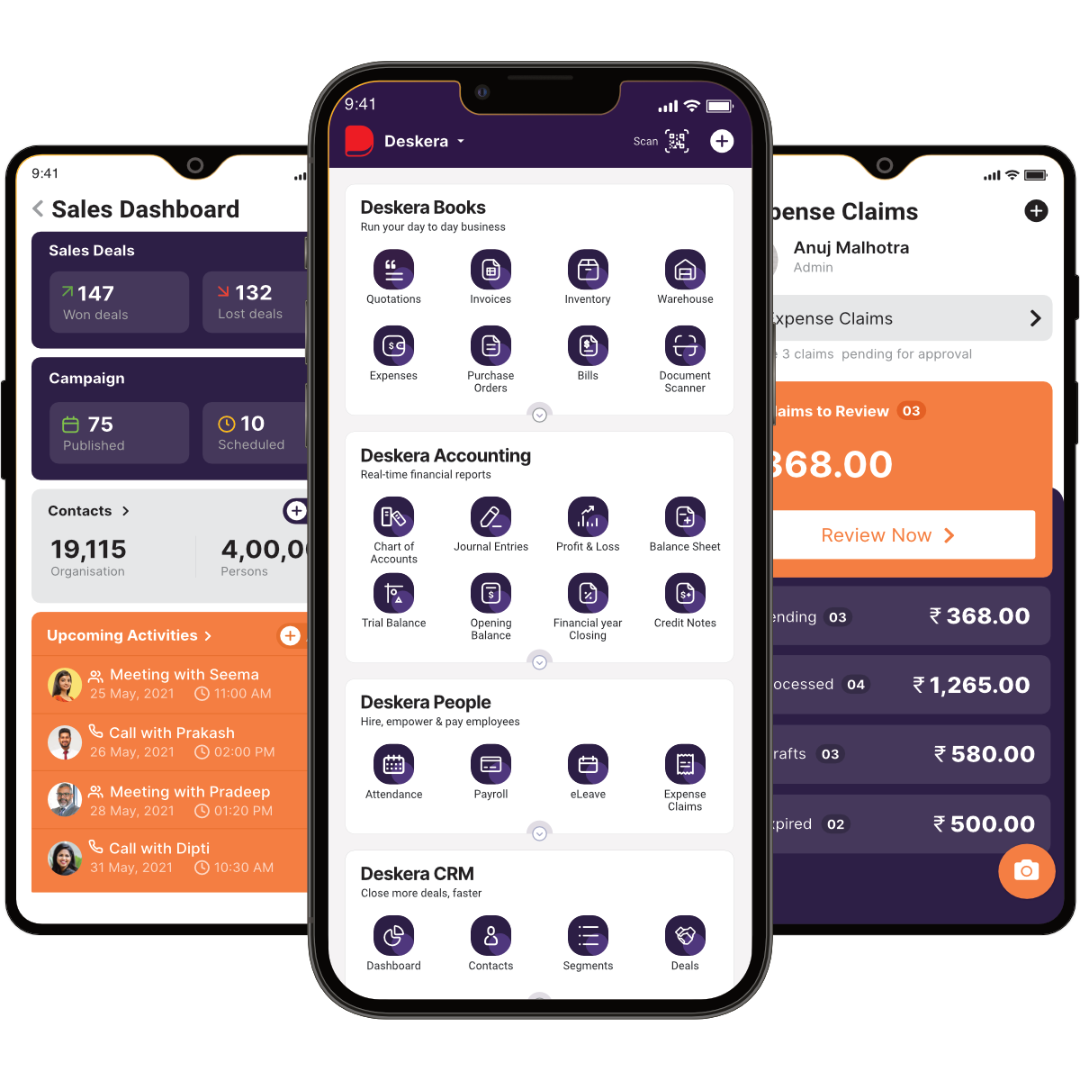

How Deskera Can Assist You?

Deskera ERP is a comprehensive system that allows you to maintain inventory, manage suppliers, and track supply chain activity in real-time, as well as streamline a variety of other corporate operations.

Deskera ERP and MRP system can help you:

- Manage production plans

- Maintain Bill of Materials

- Generate detailed reports

- Create a custom dashboard

Deskera Books enables you to manage your accounts and finances more effectively. Maintain sound accounting practices by automating accounting operations such as billing, invoicing, and payment processing.

Deskera CRM is a strong solution that manages your sales and assists you in closing agreements quickly. It not only allows you to do critical duties such as lead generation via email, but it also provides you with a comprehensive view of your sales funnel.

Deskera People is a simple tool for taking control of your human resource management functions. The technology not only speeds up payroll processing but also allows you to manage all other activities such as overtime, benefits, bonuses, training programs, and much more. This is your chance to grow your business, increase earnings, and improve the efficiency of the entire production process.

Conclusion

Demand planning is a vital component of effective inventory management. By accurately forecasting demand for products and services, companies can ensure that they have the right products available in the right place at the right time, reducing the risk of stockouts or overstocks.

Demand planners can make informed decisions through data analysis and technology that lead to more efficient supply chain operations and improved customer satisfaction. By staying up-to-date with the latest trends and developments in demand planning, companies can continue to improve their processes and stay ahead of the competition.

In today's fast-paced business environment, demand planning has become increasingly important. Companies that invest in this process and implement best practices will see significant benefits in terms of reduced costs, improved customer satisfaction, and increased profitability.

Whether you are a small business just starting out or a large multinational corporation, demand planning is a critical component of effective inventory management that should be considered.

Key Takeaways

- Companies can gain a complete picture of customer demand by using tools like data mining, predictive analytics, and machine learning.

- The demand planning process should be collaborative across the entire supply chain, from manufacturers and suppliers to logistics providers and retailers.

- By working together, companies can ensure that their demand planning processes are aligned with their overall business objectives.

- Companies should regularly review and update their demand planning processes to stay ahead of the competition and respond to changing market conditions.

- A well-designed demand planning strategy can improve customer satisfaction, reduce costs, and increase profitability.

- Companies that invest in demand planning technology and training for their employees will see the greatest benefits.

- Artificial intelligence and machine learning are becoming increasingly common in demand planning, allowing companies to make more informed and accurate predictions.

Related Articles