Have you ever wondered why some businesses always seem to have just the right amount of stock, while others constantly face shortages or excess inventory? The answer lies in demand forecasting—a strategic process that helps businesses anticipate future customer demand with accuracy. By predicting what, when, and how much customers are likely to buy, businesses can reduce waste, optimize resources, and increase profitability.

Demand forecasting isn’t just about predicting sales—it’s about understanding what your customers will want, when they’ll want it, and how much they’ll need.

In today’s fast-changing markets, demand forecasting isn’t just a nice-to-have—it’s a necessity. From retail and manufacturing to services and e-commerce, every industry relies on accurate forecasts to align production, manage supply chains, and make smarter financial decisions. Without it, companies risk overstocking, understocking, or missing out on growth opportunities altogether.

This guide will walk you through everything you need to know about demand forecasting, including its types, methods, techniques, and best practices. Whether you’re a growing startup or an established enterprise, understanding demand forecasting can help you turn uncertainty into strategic advantage.

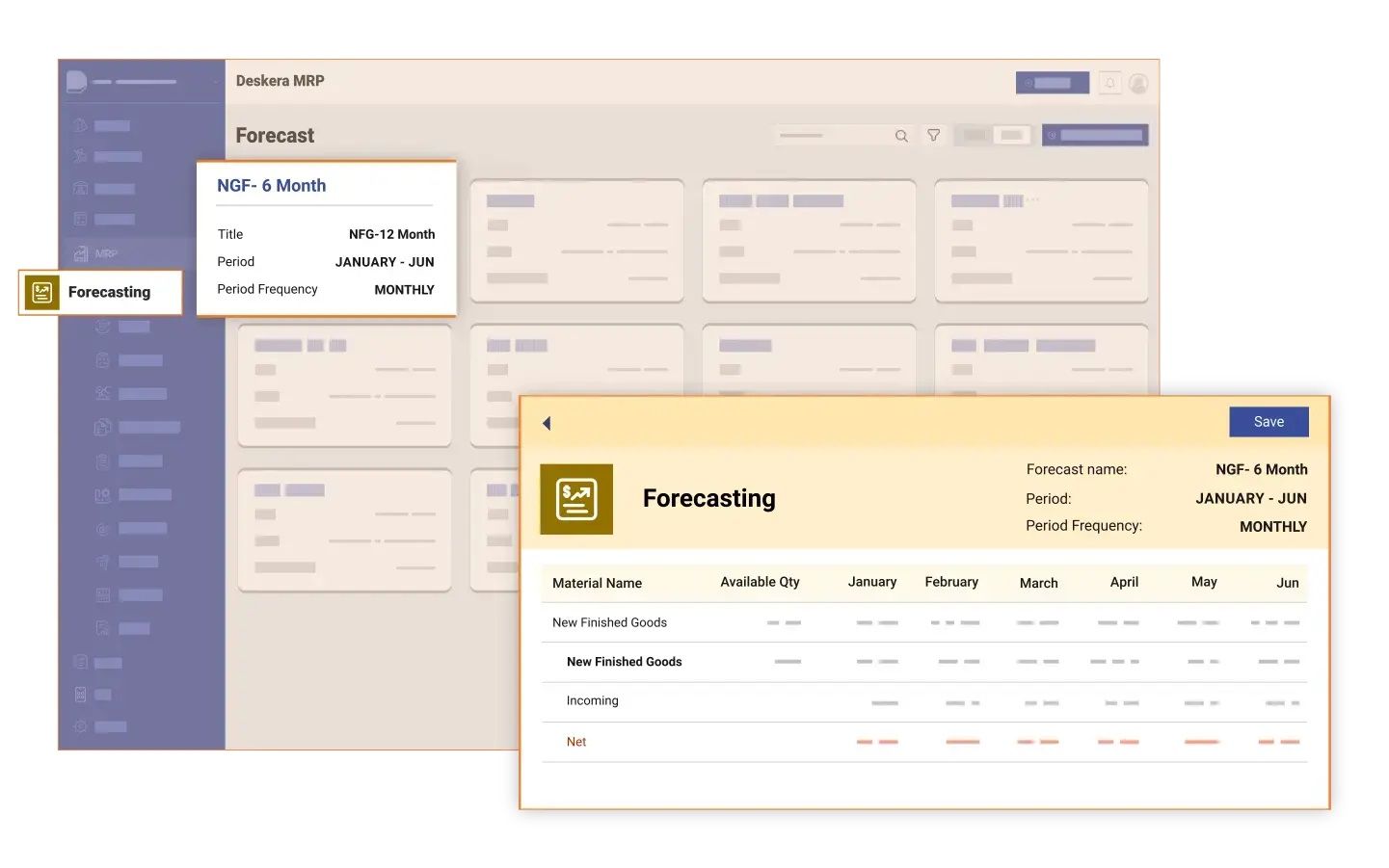

To make this process seamless, tools like Deskera MRP come into play. Deskera’s cloud-based manufacturing software integrates demand forecasting with production planning, inventory management, and procurement. With features like AI-driven insights, automation, and real-time reporting, businesses can make data-backed decisions and meet customer demand efficiently.

What is Demand Forecasting?

At its core, demand forecasting is the process of predicting customer demand for a product or service within a defined time frame. It helps businesses anticipate what customers will want, how much they’ll purchase, and when they’re likely to make those purchases. This predictive process is essential for making informed decisions about production, inventory, staffing, and overall resource allocation.

Demand forecasting can be applied at different levels:

- Product-specific forecasting – e.g., estimating how many units of a particular smartphone model will sell in the next quarter.

- Category-level forecasting – e.g., predicting total sales of luxury sedans in a given year.

- Aggregate forecasting – e.g., estimating total automobile demand across a country.

Importantly, demand forecasting isn’t limited to existing products. Companies can also forecast demand for new offerings by using market research, consumer surveys, and competitor analysis. This flexibility makes it a valuable tool across industries, whether you’re managing weekend snack sales at a grocery store or planning nationwide distribution of vehicles.

In essence, demand forecasting gives businesses the power to reduce uncertainty. By blending historical sales data, market insights, and statistical techniques, organizations can better prepare for customer needs, avoid costly stockouts or overstocks, and strategically plan for growth.

Demand Forecasting vs. Demand Planning

Have you ever wondered why some businesses always seem to have the right products at the right time while others struggle with stockouts or overstocks? The difference often comes down to understanding demand forecasting and demand planning—two closely related but distinct processes that together ensure smooth operations and satisfied customers.

Deskera MRP can integrate both processes in one platform, enabling businesses to generate AI-driven forecasts and automatically convert them into actionable plans, optimizing inventory, production, and procurement efficiently.

Key Factors Affecting Demand Forecasting

The accuracy of a forecast depends on how well you account for both controllable factors inside your business and unpredictable shifts in the market.

Demand forecasting is influenced by multiple factors that can significantly impact the accuracy and reliability of predictions. By understanding these factors, businesses can select the right forecasting methods, make informed decisions, and optimize operations. The most critical factors include:

Deskera MRP helps businesses tackle these challenges by leveraging historical data, market trends, and predictive insights to generate more accurate and actionable demand forecasts, ensuring better planning and inventory optimization.

Types of Demand Forecasting

Demand forecasting covers a broad range of approaches, each suited to different business contexts. While not every forecast fits neatly into one category, most fall within six key types. These types can be viewed across three dimensions: passive vs. active methods, short-term vs. long-term horizons, and internal vs. external focus.

1. Passive Demand Forecasting

Passive forecasting relies primarily on historical sales data and established trends. It’s a “set it and forget it” approach where forecasts are largely automated, assuming that past patterns will continue into the future.

- Best For: Companies with stable demand in non-volatile markets.

- Advantages: Easy to automate, cost-effective, requires minimal intervention.

- Limitations: Ineffective for fast-growing or highly dynamic industries where demand shifts rapidly.

Works well for businesses with predictable growth and consistent market conditions.

2. Active Demand Forecasting

Active forecasting is highly customized and dynamic. Instead of defaulting to past models, it integrates new information, specialized knowledge, and tailored statistical techniques to adapt to changing conditions.

- Best For: Fast-growing companies, startups, or industries with frequent disruptions.

- Advantages: More flexible, responsive, and capable of incorporating external signals.

- Limitations: Requires more effort, expertise, and continuous data input.

Essential for businesses in competitive or rapidly evolving markets.

3. Artificial Intelligence Forecasting

AI and machine learning (ML) represent a middle ground between passive and active forecasting. They automate much of the process while still adapting to new conditions using algorithms. For example, ERP systems may incorporate AI to enhance forecast accuracy without constant human intervention.

- Best For: Businesses with large datasets and complex demand drivers.

- Advantages: Learns and improves over time, handles complexity, reduces manual work.

- Limitations: Requires investment in data infrastructure and technical expertise.

A modern approach that bridges automation and adaptability.

4. Short-Term Demand Forecasting

Short-term forecasts typically cover a few months up to one year. They focus on immediate needs such as inventory management, staffing, and upcoming promotions.

- Best For: Day-to-day operations and seasonal planning.

- Advantages: Higher accuracy than long-term forecasts, useful for tactical decisions.

- Limitations: Limited in scope, may overlook long-term growth opportunities.

- Helps businesses optimize near-term resource allocation.

5. Long-Term Demand Forecasting

Long-term forecasts extend over several years. While they are less precise, they are valuable for strategic planning, expansion, and investment decisions.

- Best For: Strategic roadmaps, capacity planning, and investment analysis.

- Advantages: Provides direction for growth and “what-if” scenario planning.

- Limitations: Uncertainty increases with time, making projections less reliable.

- Useful even when imperfect, as it prepares organizations for multiple possible futures.

6. Internal (Micro-Level) Demand Forecasting

Internal forecasting focuses on a company’s own data, such as past sales, customer orders, financial metrics, and sales team projections. It provides granular insights at the product or departmental level.

- Best For: Product-level planning, budget forecasting, and operational efficiency.

- Advantages: Data-rich, tailored to the company’s unique situation.

- Limitations: May overlook external market forces.

- Ideal for improving internal efficiency and aligning operations with expected demand.

7. External (Macro-Level) Demand Forecasting

External forecasting examines broader industry and economic trends. It considers customer demographics, competitive dynamics, regulatory changes, and macroeconomic conditions to estimate demand.

- Best For: Business expansion, new market entry, and risk assessment.

- Advantages: Accounts for external influences that impact demand.

- Limitations: Data may be harder to obtain and less specific to the company.

- Provides a big-picture view that complements internal forecasts.

In practice, businesses often use a blend of these forecasting types. For example, a company might combine internal short-term forecasts with external long-term projections, while layering in AI to refine accuracy. The right mix depends on stability, growth stage, and industry dynamics.

Demand Forecasting Methods

Choosing the right demand forecasting method is essential for accurate business planning. Different methods suit different industries, data availability, and forecast horizons. Broadly, these methods are categorized into qualitative, quantitative, advanced, and hybrid approaches.

1. Qualitative Methods

When historical data is scarce or markets are new, qualitative methods provide valuable insights by leveraging expert opinions, customer feedback, and market research. Instead of relying on numbers, these approaches emphasize human judgment and experience.

- Market Research: Involves surveys, focus groups, and interviews to gather insights from potential customers. It is particularly useful for new product launches or unfamiliar regions.

- Expert Opinion (Delphi Method): Experts provide forecasts through multiple rounds of questionnaires, with feedback incorporated after each round.

- Sales Force Estimates: Sales representatives forecast demand based on direct customer interactions and regional market conditions.

Best Used For: New products, uncertain markets, or when reliable data is unavailable.

Advantage: Provides insights into preferences, trends, and early signals of demand shifts.

Choosing the right forecasting method is not about complexity, but about finding what best fits your business data and goals.

2. Quantitative Methods

Quantitative methods rely on historical data and statistical techniques to generate demand forecasts. These are more objective than qualitative approaches, making them effective when data is abundant and reliable.

- Time Series Analysis: Detects patterns and seasonality in past data to project future demand. Techniques include moving averages, exponential smoothing, and ARIMA models.

- Causal Models: Establish links between demand and influencing variables such as price, promotions, or GDP growth. Regression analysis is commonly applied.

Best Used For: Products with stable demand patterns or industries where external variables significantly influence demand.

Advantages: Offers measurable, data-driven forecasts that are easy to validate and refine.

Limitation: Less effective in volatile markets where past patterns don’t predict future outcomes.

3. Advanced Methods

With the rise of big data and computing power, advanced methods such as AI and simulations have gained prominence. These methods analyze vast datasets, detect complex patterns, and simulate different scenarios.

- Machine Learning & AI-Based Forecasting: Uses neural networks, decision trees, and ensemble models to uncover hidden relationships in demand data.

- Simulation Models: Techniques like Monte Carlo simulate thousands of potential scenarios, helping businesses assess uncertainty.

Best Used For: Industries with complex demand drivers, such as e-commerce, logistics, and manufacturing.

Advantages: Can process large datasets, adapt to changing conditions, and provide higher accuracy than traditional methods.

Limitation: Requires significant data and technical expertise.

4. Hybrid Methods

Since no single method is perfect, hybrid methods combine multiple approaches to improve forecast reliability. These methods balance the strengths of both qualitative insights and quantitative precision.

- Combination Forecasting: Merges expert judgment with statistical models—for example, integrating sales team estimates with time series analysis.

- Weighted Forecasting: Assigns weights to different models depending on their accuracy in past predictions.

Best Used For: Businesses operating in dynamic environments where demand is influenced by both human behavior and statistical trends.

Advantages: Produces more balanced and resilient forecasts.

Limitation: More complex to manage, as it requires careful coordination of different forecasting sources.

Demand Forecasting Techniques

While methods provide the overall approach to forecasting, techniques are the actual tools and models applied to generate predictions. These techniques vary in complexity—from simple averages to advanced statistical and AI-based models. Businesses select techniques depending on data availability, demand variability, and forecasting goals. Below are the most widely used demand forecasting techniques.

1. Moving Averages

The moving average technique smooths out fluctuations in historical demand by averaging data over a set number of periods. For example, a three-month moving average calculates the average demand of the last three months and updates it continuously.

- Best Used For: Products with stable demand patterns and limited seasonality.

- Advantages: Easy to understand and apply, reduces noise from short-term fluctuations, highlights long-term trends.

- Limitation: Not suitable for highly seasonal or volatile demand, as it lags behind sudden shifts.

- Simple yet effective for short-term forecasting in stable markets.

2. Exponential Smoothing

Exponential smoothing assigns decreasing weights to older data points, giving more importance to recent demand. Variants include:

- Simple Exponential Smoothing – for stable demand.

- Holt’s Linear Trend Model – for trend-based demand.

- Holt-Winters Seasonal Model – for demand with seasonality.

- Best Used For: Products where recent demand better indicates future trends.

- Advantages: More responsive than moving averages, adaptable for trends and seasonality.

- Limitation: Requires parameter selection (smoothing constants), which may impact accuracy.

- Versatile and widely used for short- to medium-term demand forecasting.

3. Regression Analysis

Regression analysis is a causal forecasting technique that examines the relationship between demand and one or more independent variables such as price, promotions, income levels, or economic indicators.

- Simple Regression: Relates demand to one variable (e.g., price).

- Multiple Regression: Considers multiple factors simultaneously (e.g., price, advertising, season).

- Best Used For: Markets where external factors strongly influence demand.

- Advantages: Helps identify cause-and-effect relationships and predict demand under changing conditions.

- Limitation: Requires reliable data on independent variables and assumptions about linear relationships.

- Powerful for understanding what drives demand and planning accordingly.

4. ARIMA (Auto-Regressive Integrated Moving Average)

ARIMA models are advanced time series techniques that combine autoregression, differencing, and moving averages to forecast demand. They are particularly effective in handling complex trends and seasonality.

- Best Used For: Medium- to long-term forecasting where historical data is plentiful.

- Advantages: Can capture both short-term fluctuations and long-term patterns.

- Limitation: Requires statistical expertise and model validation to avoid overfitting.

Ideal for businesses with rich historical data and relatively stable demand drivers.

5. Neural Networks & Machine Learning

Machine learning techniques, including neural networks, random forests, and ensemble models, analyze massive datasets to uncover hidden, non-linear patterns in demand. Neural networks mimic the human brain by learning relationships across multiple variables.

- Best Used For: Complex, fast-changing industries like e-commerce or supply chain logistics.

- Advantages: Highly accurate, adaptive, and capable of processing vast, unstructured data.

- Limitation: Data-intensive, requires technical expertise, and can be a “black box” with limited interpretability.

- Suitable for businesses investing in advanced analytics and digital transformation.

6. Naïve Forecasting

Naïve forecasting assumes that future demand will be the same as the most recent observed value. For example, if sales last month were 1,000 units, the forecast for the next month is also 1,000.

- Best Used For: Short-term forecasts in stable markets or as a benchmark model.

- Advantages: Extremely simple, requires no statistical knowledge or tools.

- Limitation: Ignores trends, seasonality, and external influences, making it less reliable for long-term planning.

- Useful as a baseline to compare with more advanced techniques.

7. Seasonal Indexes

Seasonal indexing adjusts forecasts to account for recurring seasonal demand patterns. By calculating seasonal factors from historical data, businesses can scale forecasts up or down during high- and low-demand periods.

- Best Used For: Products with predictable demand cycles (e.g., holidays, back-to-school season).

- Advantages: Enhances accuracy for seasonal industries like retail, tourism, and agriculture.

- Limitation: Requires several years of consistent historical data to identify stable seasonal patterns.

- Essential for industries where seasonality plays a dominant role.

8. Econometric Models

Econometric models extend regression by including multiple equations and variables, simulating the interactions between demand drivers like GDP, inflation, consumer spending, and interest rates.

- Best Used For: Macro-level forecasting in industries influenced by economic policy or global trends.

- Advantages: Provides insights into how changes in the economy impact demand.

- Limitation: Complex to design, requiring specialized econometric knowledge and reliable data.

- Valuable for long-term planning in manufacturing, finance, and energy sectors.

9. Judgmental Forecasting

Judgmental forecasting uses managerial or expert intuition rather than strict models. It includes brainstorming sessions, executive reviews, and informal predictions.

- Best Used For: New product launches, emerging markets, or crisis scenarios where data is limited.

- Advantages: Flexible, quick to implement, and can incorporate insights not captured in data.

- Limitation: Highly subjective, prone to biases and inconsistent accuracy.

- Best applied in combination with data-driven methods.

10. Collaborative Forecasting (CPFR)

Collaborative Planning, Forecasting, and Replenishment (CPFR) is a technique where businesses share data across the supply chain with suppliers, distributors, and retailers.

- Best Used For: Supply chains where collaboration reduces uncertainty and improves alignment.

- Advantages: Improves transparency, reduces stockouts, and aligns production with market demand.

- Limitation: Requires strong relationships, trust, and data integration across partners.

- Powerful for modern, interconnected supply chains.

11. Monte Carlo Simulation

Monte Carlo simulation generates thousands of random demand scenarios based on probability distributions of demand drivers. It estimates not just a single forecast but a range of possible outcomes.

- Best Used For: High-uncertainty environments like finance, energy, and complex manufacturing.

- Advantages: Quantifies risk and provides a probability range rather than a single forecast.

- Limitation: Requires statistical expertise and computational resources.

- Excellent for risk analysis and scenario planning.

12. Panel Consensus Forecasting

This technique aggregates demand forecasts from multiple stakeholders (sales, marketing, finance, operations) to form a unified projection.

- Best Used For: Cross-functional organizations where different teams hold unique insights.

- Advantages: Builds consensus, reduces bias from single sources, and integrates diverse viewpoints.

- Limitation: Can be time-consuming and subject to negotiation rather than pure accuracy.

- Strengthens alignment across departments for strategic planning.

Choosing the Right Demand Forecasting Method

Selecting the right demand forecasting method is essential for businesses to predict future demand accurately and make informed operational and strategic decisions.

The choice of method depends on factors such as product type, data availability, forecast horizon, and business goals. The following considerations can guide you in choosing the most suitable forecasting approach.

1. Understand the Nature of Your Product and Market

Product Lifecycle Stage: Determine whether your product is new, mature, or declining. New products often require qualitative methods like market research, while mature products are better suited for quantitative approaches like time series analysis.

Market Dynamics: Evaluate the volatility and competitiveness of your market. Rapidly changing markets may need advanced methods such as causal models or machine learning to account for multiple influencing factors.

2. Assess Data Availability and Quality

Historical Data: Robust historical sales data is critical for quantitative methods like time series analysis. Incomplete or inconsistent data can reduce forecast accuracy.

External Data Sources: Consider access to external indicators such as economic trends, market insights, and customer behavior, which are essential for causal or advanced forecasting models.

3. Define the Forecasting Time Horizon

Short-Term Forecasting: For weeks or months ahead, moving averages, exponential smoothing, or sales force estimates are often effective.

Long-Term Forecasting: For forecasts extending beyond a year, consider methods that incorporate broader trends and external factors, such as causal models or simulation techniques.

4. Determine the Complexity of Demand Patterns

Stable Demand Patterns: Products with consistent demand over time can be forecasted using simpler approaches like moving averages or basic time series analysis.

Complex Demand Patterns: Irregular or seasonal demand may require exponential smoothing with seasonal adjustments or machine learning models for higher accuracy.

5. Evaluate the Need for Accuracy and Detail

High Accuracy Required: For high-cost or perishable goods, advanced methods like machine learning or combination forecasting provide precise predictions.

Moderate Accuracy Sufficient: For less critical applications, expert opinion or simple moving averages may suffice.

6. Consider the Resources and Expertise Available

Technical Expertise: Advanced methods need specialized skills and tools. Ensure your team has the capability or access to external support.

Budget and Time Constraints: Simpler methods are often faster and more cost-effective, while sophisticated methods require greater investment in software, time, and training.

7. Match the Method to Business Objectives

Operational Efficiency: For day-to-day operations like inventory management and production scheduling, time series analysis or exponential smoothing can provide the required precision.

Strategic Planning: For long-term planning, methods like causal models or simulation techniques, which consider multiple influencing factors, are more suitable.

8. Consider a Hybrid Approach

Combining Methods: Sometimes a combination of methods delivers the best results. For instance, time series analysis can guide short-term forecasts, while expert opinion or causal models support long-term strategic planning.

Example Scenarios

- New Product Launch: Market research and expert opinion help forecast demand when historical data is unavailable.

- Seasonal Products: Exponential smoothing with seasonal adjustments can capture predictable fluctuations in holiday items.

- Stable, Mature Products: Moving averages or simple time series analysis can be used for routine forecasting of products with consistent demand.

Choosing the right demand forecasting method requires a careful analysis of your product, market, data availability, and business objectives. By aligning your approach with these factors, businesses can improve forecast accuracy, optimize resource allocation, enhance customer satisfaction, and boost overall financial performance.

Comparison of Demand Forecasting Techniques

To make it easier to evaluate, here’s a comparison of major demand forecasting techniques based on their category, description, best use cases, advantages, and limitations:

Benefits of Demand Forecasting

Demand forecasting is a critical tool that allows businesses to anticipate future demand and make informed operational and strategic decisions. Companies that implement effective demand forecasting can unlock multiple benefits, from better inventory management to enhanced decision-making and financial planning.

When done right, demand forecasting transforms guesswork into strategy, helping businesses reduce waste and maximize profitability.

Below are the key advantages of demand forecasting explained in detail.

Informed Scaling

Accurate demand forecasting helps businesses scale their operations at the right pace. Growing too slowly can lead to unmet customer needs, while growing too fast can be expensive and drain cash reserves. By understanding future demand trends, businesses can plan operational capacity appropriately, mitigating the risks of overexpansion or under-preparedness.

Budgeting and Financing

Demand forecasts allow businesses to create budgets that align with anticipated customer needs. They guide investment decisions related to inventory, production, staffing, and equipment. Additionally, robust forecasts help differentiate between temporary demand spikes and long-term trends, aiding decisions about borrowing or attracting investors. Lenders and investors are also more likely to support businesses backed by credible demand insights.

Inventory Management

Demand forecasting is crucial for managing inventory efficiently across various types of goods, including perishable items, packaged goods, or service-based offerings. Benefits include:

- Reducing storage costs: Avoid overproduction or over-ordering, saving on storage and carrying costs.

- Reducing stockouts: Minimize the risk of backorders and lost sales.

- Efficient reordering: Forecasts help determine the right time and quantity for restocking.

- Improved inventory positioning: Geographic and product-level forecasts enable optimal inventory placement in warehouses and stores.

- Better revenue management: Businesses relying on services or experiences, like hotels or golf courses, can optimize pricing and promotions based on forecasted demand.

Better High-Level Decisions

Accurate demand forecasts provide actionable insights for strategic business decisions. Companies can decide whether to discontinue or launch products, expand into new markets, or invest in new product lines. Both micro-level operational choices and macro-level strategic planning benefit from precise demand insights.

Improved Customer Satisfaction

By predicting demand accurately, businesses can ensure product availability when customers need it. This reliability reduces delays or stockouts, leading to higher customer satisfaction and loyalty.

Cost Savings

Aligning production, procurement, and inventory with forecasted demand reduces waste, lowers storage costs, and minimizes expenses from emergency orders or expedited shipping. Over time, these efficiencies generate significant cost savings.

Optimized Resource Allocation

Demand forecasting allows companies to deploy resources—labor, materials, and capital—more effectively. By aligning resources with predicted demand, businesses can operate more efficiently and increase profitability.

Better Financial Planning and Budgeting

Reliable forecasts inform revenue projections, investment decisions, and cash flow management. Businesses can plan financial strategies with greater accuracy, reducing uncertainty and risk.

Enhanced Decision-Making

Data-driven forecasting empowers leaders to make informed operational and strategic decisions, from production scheduling to marketing campaigns. This improves alignment with market demand and enhances overall business performance.

Increased Agility and Responsiveness

Companies that leverage demand forecasting can quickly adapt to market changes, whether a sudden demand surge or unexpected downturn. Reliable forecasts provide the agility needed to maintain a competitive edge in dynamic markets.

Risk Reduction

Demand forecasting helps identify potential risks in operations and supply chains before they occur. Early detection of demand fluctuations allows businesses to mitigate financial, operational, and inventory-related risks.

Supplier Relationship Management

With accurate forecasts, businesses can communicate more effectively with suppliers. Predictable orders strengthen supplier partnerships, reduce lead times, and often result in better pricing and priority access to materials.

Market Expansion and Product Launch Planning

Demand forecasting helps companies assess the potential of new markets or products. By estimating demand in different regions or customer segments, businesses can optimize launch strategies and resource allocation for new initiatives.

Sustainability and Waste Reduction

By producing and stocking only what is likely to be sold, demand forecasting reduces overproduction and excess inventory, contributing to more sustainable business operations and lower environmental impact.

Workforce Planning

Forecasting demand enables better workforce management. Businesses can align staffing levels with predicted demand, avoiding underutilization or overstaffing, which improves productivity and reduces labor costs.

Competitive Advantage

Businesses with accurate demand forecasting are better positioned to respond faster and more effectively than competitors. Timely insights into market trends and consumer needs allow for proactive strategy adjustments that strengthen market position.

Key Challenges in Demand Forecasting and How to Overcome Them

No forecast is perfect, but businesses that adapt quickly to change are the ones that thrive.

Demand forecasting is essential for businesses, but it comes with a variety of challenges that can affect accuracy and decision-making. Each challenge can be addressed using specific strategies, tools, and best practices to improve forecasting outcomes.

1. Data Quality and Availability

Challenge: Accurate forecasting depends on high-quality data, yet businesses often face incomplete, outdated, or inconsistent datasets.

Solution:

- Implement Data Management Systems: Centralize and clean data to ensure accuracy and consistency.

- Regular Data Audits: Conduct audits to identify and correct inaccuracies.

- Invest in Data Analytics Tools: Leverage analytics tools to process large datasets, fill gaps, and identify trends.

2. Rapidly Changing Market Conditions

Challenge: Economic shifts, technological advances, and sudden changes in consumer preferences can disrupt forecasts.

Solution:

- Adopt Agile Forecasting Methods: Update forecasts frequently based on real-time data.

- Use Scenario Planning: Prepare for multiple potential market conditions.

- Monitor Market Indicators: Continuously track key market metrics and adjust forecasts as needed.

3. Unpredictable External Events

Challenge: Natural disasters, pandemics, and political instability can drastically alter demand patterns.

Solution:

- Build Flexibility into Supply Chains: Design systems that can adapt quickly to changes.

- Create Contingency Plans: Prepare plans for different external events.

- Use Real-Time Data: Incorporate live data and external signals to adjust forecasts.

4. Long Lead Times

Challenge: Industries like manufacturing often face long lead times that complicate accurate forecasting.

Solution:

- Implement Just-In-Time (JIT) Systems: Reduce reliance on long-term forecasts and enable responsive production.

- Use Advanced Planning Tools: Optimize production schedules based on forecasted demand.

- Collaborate with Suppliers: Improve lead time estimates and align production with demand.

5. Seasonal and Cyclical Variations

Challenge: Distinguishing between regular seasonal patterns and other demand changes can be tricky.

Solution:

- Apply Seasonal Adjustment Techniques: Use methods like exponential smoothing with seasonality.

- Analyze Multiple Years of Data: Identify consistent seasonal patterns over time.

- Integrate Marketing and Sales Input: Factor in planned promotions or events affecting demand.

6. Product Life Cycle Variability

Challenge: Different product lifecycle stages have varying demand patterns.

Solution:

- Use Life Cycle-Based Forecasting Models: Apply models like the Bass diffusion model for new products.

- Monitor Product Performance Closely: Adjust forecasts as products progress through lifecycle stages.

- Forecast with Flexibility: Revise forecasts frequently, especially during introduction and decline phases.

7. Complexity of Demand Drivers

Challenge: Demand is influenced by multiple factors such as pricing, marketing, and economic conditions.

Solution:

- Use Causal Models: Apply regression analysis to understand relationships between variables.

- Leverage Machine Learning: Handle complex, nonlinear interactions between demand drivers.

- Segment the Market: Analyze demand drivers by specific customer or geographic segments.

8. Technological Disruptions

Challenge: Rapid technological advances can disrupt existing demand patterns.

Solution:

- Stay Informed on Trends: Monitor technology trends and anticipate their impact on demand.

- Invest in Predictive Analytics: Forecast how new technologies may influence product demand.

- Diversify Product Portfolio: Reduce risk by offering multiple product options.

9. Inaccurate Forecasting Models

Challenge: Using outdated or inappropriate forecasting models can lead to errors.

Solution:

- Regularly Review and Update Models: Ensure models remain accurate and relevant.

- Conduct Back Testing: Evaluate models against historical data.

- Experiment with Multiple Models: Identify which model provides the most accurate forecasts.

10. Organizational Misalignment

Challenge: Lack of coordination between departments can lead to inconsistent forecasting inputs.

Solution:

- Foster Cross-Departmental Collaboration: Encourage communication across sales, marketing, and supply chain teams.

- Implement Integrated Business Planning (IBP): Align all functions toward shared forecasting goals.

- Standardize Forecasting Procedures: Develop consistent processes and tools across departments.

11. Data Wrangling Challenges

Challenge: Accessing and preparing high-quality data from legacy systems or multiple sources can be time-consuming.

Solution:

- Consolidate data sources and implement automated ETL processes.

- Standardize data formats for seamless integration into forecasting tools.

12. Selection Bias

Challenge: Forecasts based on surveys or expert input can be skewed if respondents are not representative.

Solution:

- Ensure diverse and representative data collection.

- Use statistical adjustments to correct for known biases.

13. “Bad” Recordkeeping

Challenge: Historical data may not have been collected with forecasting in mind, leading to errors.

Solution:

- Audit and clean historical data before using it for forecasts.

- Maintain records with future forecasting requirements in mind.

14. Pivoting and Business Agility

Challenge: Frequent changes in business strategy or product presentation can make demand unpredictable.

Solution:

- Include internal operational signals in forecasting models.

- Build dynamic models that can quickly adapt to strategic shifts.

By identifying these challenges and applying the corresponding strategies, businesses can improve forecasting accuracy, optimize inventory, enhance financial performance, and make more informed decisions.

How to Forecast Demand: A Step-by-Step Guide

A forecast is only as strong as the process behind it—structured steps ensure accuracy and reliability.

Demand forecasting is not a one-time task—it’s an ongoing process that requires clarity, reliable data, and the right methods. Below is a step-by-step guide that businesses can follow to forecast demand effectively and improve decision-making.

1. Define the Objectives

The first step is to establish why you are forecasting demand. Clarity here shapes the entire process.

- Identify the purpose: Do you want to optimize inventory, plan production schedules, or set sales targets?

- Set measurable goals: For example, “reduce stockouts by 15%” or “increase forecast accuracy by 10%.”

- Decide on the scope: Will the forecast cover all product lines, or focus on specific regions or segments?

- Align with business needs: Determine whether the forecast should be conservative, ambitious, or neutral, based on company strategy.

2. Collect and Analyze Data

Accurate forecasting relies on relevant and high-quality information.

- Gather historical data: Past sales, customer orders, and inventory levels are crucial starting points.

- Consider external factors: Market trends, seasonality, competitor moves, and economic indicators can all influence demand.

- Segment the data: Break it into product categories, customer groups, or regions for more precise insights.

- Validate data quality: Ensure accuracy, consistency, and completeness before moving to the next step.

3. Choose a Forecasting Method

The method depends on your data availability, product type, and goals.

- Qualitative methods: Use when historical data is limited (e.g., expert judgment, Delphi technique, or market surveys).

- Quantitative methods: Apply when data is available. Popular techniques include:

- Moving Averages: Smooths out fluctuations.

- Exponential Smoothing: Responds quickly to recent trends.

- Regression Analysis: Explains demand through variables like pricing or marketing.

- Machine Learning Models: Handle complex, non-linear demand patterns.

4. Create the Demand Forecast

Once you’ve chosen a method, it’s time to build the forecast.

- Develop scenarios: Create best-case, worst-case, and most-likely forecasts.

- Leverage software tools: Demand forecasting software or ERP systems like Deskera MRP can automate calculations, integrate real-time data, and improve accuracy.

- Validate assumptions: Compare results against historical performance and current conditions.

5. Implement and Monitor the Forecast

A forecast is only valuable if applied correctly.

- Integrate into operations: Use forecasts to plan procurement, inventory, staffing, and budgeting.

- Track accuracy: Compare actual demand to forecasts using KPIs like Mean Absolute Deviation (MAD) or Mean Squared Error (MSE).

- Adjust dynamically: Refine forecasts in response to new data, unexpected events, or market shifts.

6. Review and Improve Continuously

Forecasting is iterative—it gets better with regular refinement.

- Post-forecast analysis: Assess where forecasts aligned or deviated from reality.

- Update models and data: Revise assumptions, add new data sources, and adapt methods to market changes.

- Collect feedback: Involve teams across sales, operations, and finance to align forecasts with business objectives.

- Commit to improvement: Treat forecasting as a continuous cycle of learning and refining.

By following these steps, businesses can create reliable demand forecasts that improve operational efficiency, reduce risks, and support smarter decision-making.

Best Practices for Effective Demand Forecasting

Demand forecasting is both an art and a science. While historical data and advanced models can give you direction, aligning forecasts with real-world conditions, technology, and cross-departmental insights ensures maximum accuracy.

Implementing best practices not only reduces the risk of overstocking or understocking but also enhances customer satisfaction, operational efficiency, and long-term profitability.

1. Use Multiple Forecasting Methods

- Diversify techniques: Relying on a single method can limit accuracy. Combine qualitative methods (e.g., expert judgment, surveys) with quantitative ones (e.g., time series, regression) to balance insights.

- Test and compare: Regularly benchmark models against historical data to identify the most effective ones for different products or markets.

2. Incorporate Real-Time Data

- Leverage real-time analytics: Dynamic markets require live updates from sales, marketing, and customer behavior data.

- Respond quickly: Immediate integration of promotions, campaigns, or competitor moves into forecasts helps refine short-term predictions.

3. Segment Your Forecast

- Break down demand: Create separate forecasts for product categories, customer groups, or regions.

- Customize methods: Seasonal products may need time series models, while new launches might benefit more from expert judgment.

4. Regularly Review and Adjust Forecasts

- Track forecast accuracy: Use metrics like MAPE, MAD, or MSE to evaluate and refine predictions.

- Stay agile: Be ready to adjust forecasts in response to sudden demand shifts, market disruptions, or new product launches.

5. Collaborate Across Departments

- Gather broad insights: Sales teams offer customer knowledge, marketing contributes promotional data, and finance provides macroeconomic insights.

- Ensure alignment: Cross-functional collaboration ensures forecasts support overall business goals.

6. Account for External Factors

- Monitor macroeconomic indicators: Inflation, consumer spending, and industry shifts can strongly influence demand.

- Track competitors: Keep tabs on pricing changes, promotions, and product launches in your industry.

7. Incorporate Seasonality and Cyclicality

- Adjust for seasonality: Use historical data to plan around predictable demand peaks (e.g., holidays, festivals).

- Recognize cycles: Factor in longer-term patterns like industry growth phases or economic cycles.

8. Utilize Advanced Forecasting Tools

- Invest in AI and ML: Machine learning algorithms can analyze large, complex datasets and capture non-linear demand patterns.

- Automate workflows: Reduce human error and free analysts to focus on interpreting insights rather than manual calculations.

9. Build Flexibility into Your Supply Chain

- Maintain buffer stock: Protect against unexpected demand spikes or supply chain delays.

- Agility in operations: Shorten lead times and strengthen supplier relationships to respond quickly to demand changes.

10. Conduct Scenario Planning

- Prepare multiple outcomes: Develop best-case, worst-case, and most-likely scenarios for uncertainty.

- Run sensitivity analysis: Evaluate how changes in variables (like price, marketing spend, or economic conditions) affect demand.

11. Maintain Consistent and Complete Data

- Standardize data practices: Ensure data collection and storage follow consistent rules across departments.

- Audit regularly: Identify missing, duplicate, or inconsistent entries that could distort forecasts.

12. Reduce Manual Errors With Automation

- Centralize systems: Use ERP or forecasting software to aggregate data from multiple sources.

- Automate reporting: Minimize errors in calculations and streamline communication with stakeholders.

13. Align Forecasting With Strategic Goals

- Set clear direction: Define how forecasts will influence decisions such as inventory planning, market entry, or resource allocation.

- Focus on critical metrics: Avoid wasting resources forecasting discontinued products or irrelevant markets.

14. Collaborate With Different Teams

- Cross-functional synergy: Sales, marketing, operations, and finance each hold unique insights.

- Regular updates: Collaborative review meetings keep forecasts aligned with ongoing business developments.

Effective demand forecasting requires discipline, technology, and collaboration. Businesses that consistently apply these best practices not only forecast with greater accuracy but also gain a strategic advantage by aligning supply with demand in an ever-changing market.

Great forecasting combines the power of data with human judgment—it’s science enhanced by experience.

How can Deskera MRP Help You With Demand Forecasting?

Deskera MRP can significantly enhance your demand forecasting capabilities by leveraging advanced tools and features designed to improve accuracy and efficiency.

Here's how Deskera MRP can help with demand forecasting:

1. Automated Data Collection and Integration

Deskera MRP simplifies the process of data collection by automatically gathering data from various sources, including sales orders, inventory levels, and production schedules. This real-time data integration allows you to generate accurate demand forecasts quickly, reducing manual effort and the risk of errors.

2. Advanced Forecasting Models

The platform offers robust forecasting models that analyze historical data to predict future demand. Deskera MRP uses machine learning algorithms and statistical methods to identify trends and patterns, providing you with reliable forecasts that can adapt to changes in the market.

3. Scenario Planning and What-If Analysis

Deskera MRP enables you to create multiple forecast scenarios to plan for different market conditions. Whether you're preparing for a best-case, worst-case, or most likely scenario, the platform allows you to simulate various outcomes and adjust your strategies accordingly.

4. Integration with Supply Chain Management

By integrating demand forecasts with supply chain management, Deskera MRP helps you align production schedules, optimize inventory levels, and reduce lead times. This integration ensures that your business is always prepared to meet customer demand without overstocking or stockouts.

5. Real-Time Reporting and Dashboards

Deskera MRP provides real-time reporting and interactive dashboards, giving you instant access to key metrics and insights. These tools allow you to monitor demand forecasts, track accuracy, and make data-driven decisions that support your business goals.

6. Collaborative Planning

Deskera MRP facilitates cross-departmental collaboration by allowing teams to share data and insights within a unified platform. This collaboration ensures that sales, marketing, finance, and operations are aligned, leading to more accurate and cohesive demand forecasts.

Key Takeaways

- Demand forecasting is more than just predicting sales—it’s about aligning supply with customer needs, improving financial planning, and enabling smarter decision-making for long-term business growth.

- Internal factors like pricing, promotions, and product portfolio, along with external ones like market trends, seasonality, and economic shifts, directly impact the accuracy of demand forecasts.

- Businesses can apply different forecasting types such as short-term, medium-term, long-term, passive, and active forecasting—each serving a unique purpose, from daily operations to long-range planning.

- Organizations can choose between qualitative methods (expert judgment, Delphi method, market surveys) and quantitative methods (time series analysis, regression models, econometric approaches) based on data availability.

- Techniques like moving averages, exponential smoothing, causal models, machine learning, and trend projection offer diverse levels of accuracy. The right technique depends on your industry and data maturity.

- Effective demand forecasting helps businesses reduce costs, optimize inventory, improve customer satisfaction, support strategic planning, and maximize profitability, making it a vital tool for sustainable growth.

- Poor data quality, sudden market changes, and unpredictable global events pose challenges. Businesses need agile models, better data integration, and advanced analytics to minimize errors.

- A systematic approach—objective setting, data collection, method selection, forecast generation, monitoring, and feedback loop—ensures structured and reliable demand predictions.

- Leveraging multiple models, real-time data, AI/ML tools, scenario planning, and cross-department collaboration ensures accuracy, adaptability, and strategic alignment with business goals.

By utilizing Deskera MRP, businesses can improve their demand forecasting accuracy, reduce costs, and enhance overall operational efficiency. This comprehensive approach helps companies stay ahead of market trends and better meet customer needs.

Related Articles