According to the most recent data from the Bureau of Labor Statistics, the number of US companies impacted by dead stock has risen drastically in the past year.

In April 2021, the number of businesses with more than 50 percent of their inventory in dead stock was 8.3 percent, up from 6.8 percent in April 2020.

Dead stock is wrong for a company because it ties up capital and resources that could be used more effectively elsewhere. It also reduces the space available to store new products and can lead to a loss of revenue due to the cost of storing and holding the dead stock. Additionally, it can create negative brand perception due to the perception of having out-of-date or unwanted stock.

Dead stock is a term used to describe products no longer in production, usually due to a company going out of business or discontinuing a product line. This article will discuss the concept of dead stock and its related factors.

- What is Dead Stock?

- 5 Ways to Avoid Dead Stock

- What to do with Dead Stock?

- Overview of Inventory Management

- 6 Causes of Dead Stock

- Impact of Dead Stock on Inventory Management

- Strategies to Reduce Dead Stock

- Eliminating Dead Stock with Inventory Management Software

- Conclusion

- How can Deskera Help You?

- Key Takeaways

- Related Articles

What is Dead Stock?

Dead stock is inventory that is not sold or expected to be sold in the future. This includes items that are out of season, have been discontinued, or are no longer in demand. Dead stock can be a significant financial burden to a company, as it ties up resources that could be used elsewhere.

Dead stock often represents a large financial loss for companies, as they have spent money producing and stocking the inventory but cannot recover the cost of the goods by selling them.

5 Ways to Avoid Dead Stock

Now that we know the hazards of dead stock, let’s look at how you can avoid it.

Monitor Inventory Levels Regularly

To prevent dead stock, keeping a close eye on inventory levels and trends is essential. Monitor inventory regularly to understand when and how much to order. This will ensure you don’t end up with too much or too little stock.

Analyze Sales Data

Analyzing sales data can help you identify which products are selling quickly and which are not. This can help you adjust the amount of inventory you order for each product.

Implement Just-in-Time Inventory Management

Just-in-time inventory management is a technique that helps to reduce the amount of inventory held by an organization. It ensures that stock is delivered just in time for use so that you only order what you need and don’t end up with excess stock.

Utilize Automated Reordering Systems

Automated reordering systems can help to reduce the risk of dead stock by automatically ordering new stock when the existing stock reaches a certain level. This helps ensure you never run out of stock and don’t end up with too much.

Utilize Discounts and Promotions

Offering discounts and promotions on certain items can help reduce the risk of dead stock by encouraging customers to purchase products they may otherwise not be sold. This is especially useful for products that are seasonal or have low demand.

What to do with Dead Stock?

Dead stock is inventory that a business has acquired but which will never be sold due to obsolescence, overstock, or other reasons. Dealing with dead stock can be a difficult and frustrating process, but it is an important part of inventory management.

Identify Dead Stock

To properly manage dead stock, businesses should first identify it. This can be done by running regular inventory reports and analyzing them to find items that have not sold in a certain period (usually several months).

Once identified, businesses should determine the cause of the dead stock. Was it due to overstocking? Was the item out of date? Is it something that the company no longer carries? Understanding why an item is no longer selling is key in preventing similar items from becoming dead stock in the future.

Once a business has identified and understood the cause of the dead stock, it’s time to determine what to do with it. There are several options, depending on the item in question.

Donate: One option is to donate the items to a charitable organization. This is a great way to eliminate unwanted inventory while also giving back to the community.

Clearance Sale: Another option is to hold a clearance sale. This can be done both in-store and online. Offering items at a discounted rate can help to move them quickly and reduce inventory levels.

Return to Suppliers: A third option is to return the items to the manufacturer or supplier. Many suppliers will accept returns of dead stock, especially if the items are still in good condition. This can help reduce the amount of inventory a business holds and sometimes even result in a refund.

Dispose of: Finally, a business can simply dispose of the dead stock. This is often the most cost-effective solution, but it should be done with care and consideration for the environment.

Managing dead stock is an important part of inventory management. With proper identification, understanding, and disposal, businesses can reduce the amount of dead stock they carry and prevent their inventory from becoming a burden.

Overview of Inventory Management

Inventory management is the process of overseeing and controlling the ordering, storage, and use of materials or products. It includes managing raw materials, parts, finished products, and the associated inventory control systems and procedures. It is an important part of the supply chain management process, as it helps to ensure that the right amount of inventory is available at the right time and place.

Inventory management involves tracking materials or products from the point of purchase to the point of sale. This includes monitoring the quantity and quality of inventory and managing the lead time, backorders, and other associated costs. It also involves setting and tracking inventory levels and making decisions about the size and frequency of inventory replenishment.

Goal of Inventory Management

The goal of inventory management is to maintain an optimal balance between inventory costs and customer service levels. This can be achieved by ensuring that the right amount of inventory is available at the right time and place while minimizing the risk of stockouts.

Organizations must consider factors such as inventory turnover, lead time, and cost of goods sold to achieve this. Inventory management requires a thorough understanding of the organization’s supply chain and operations. It also requires the ability to forecast and predict future demand, as well as the ability to respond quickly to changes in demand.

Organizations must also consider the cost of inventory, including the cost of purchasing, storing, and handling inventory. Additionally, they must consider the cost of obsolescence, which is the cost associated with inventory that is no longer useful.

Consider Risks in Inventory Management

Organizations must also consider the potential risks associated with inventory management. This includes the risk of stockouts, which can lead to customer dissatisfaction and decreased revenue. Additionally, organizations must be aware of the potential for theft or damage to inventory.

Mitigate Risks in Inventory Management

To mitigate these risks, organizations must ensure that they have proper inventory control systems and procedures in place. In short, inventory management is a critical component of the supply chain process, as it helps to ensure that the right amount of inventory is available at the right time and place.

Organizations can effectively manage their inventories through proper planning and forecasting to minimize stockouts and maximize customer satisfaction.

6 Causes of Dead Stock

Avoiding dead stock begins with recognizing the causes. The organizations must undertake measures that help them identify these causes.

This section enumerates five causes of dead stock. Let’s take a look.

- Poor inventory management: Poor inventory management can lead to dead stock, as companies may not have the right systems in place to accurately track and monitor their stock levels.

- Excess stock: Companies may hold too much stock, which can lead to dead stock. This is especially true if the stock is perishable or seasonal since it may not be able to be sold before its expiration date.

- Outdated stock: Outdated stock can quickly become dead stock if companies don't actively monitor and adjust their inventory levels to reflect demand.

- Unforeseen events: Unforeseen events, such as a natural disaster or sudden changes in market trends, can lead to dead stock if companies don't have the means to quickly adjust their stock levels in response.

- Poor forecasting: Companies may not accurately forecast their future demand, leading to an excess of stock that can't be sold in time. If a company overestimates the demand for a particular product, it can result in dead stock.

- Quality Issues: Poor product quality can lead to customer dissatisfaction and make it more difficult to sell the product. If a company is unable to meet customer expectations due to poor quality, it can lead to an excess of unsold inventory, which can lead to dead stock. Quality assurance is important in reducing dead stock by ensuring that customers receive a product that meets their expectations.

Impact of Dead Stock on Inventory Management

Dead stock is inventory that is not selling and is sitting in a warehouse or on store shelves. This inventory can significantly negatively impact inventory management because it ties up inventory capital that could be better used for other purposes.

- Dead stock can lead to a build-up of obsolete items which can create storage and organizational problems, leading to higher inventory carrying costs.

- Dead stock can lead to a decrease in cash flow because the inventory is not being sold, resulting in a loss of potential profit.

- Dead stock can also lead to inaccurate inventory counts, which can have wider implications for inventory forecasting and replenishment. This can lead to stock shortages and stock-outs, resulting in customer dissatisfaction and missed sales.

It also leads to higher storage and handling costs and eventually to the need to dispose of the stock. Having too much dead stock can also impact the accuracy of forecasts and the ability to meet customer demand.

Finally, it can also affect customer service levels, as it takes up space that could be used to store more in-demand items.

Cost Implications

Dead stock is inventory that has been sitting in storage for a long period of time, usually a year or more, without being sold. This can be a costly burden for businesses since the money tied up in the inventory is not used for other purposes.

As such, it is important to properly manage dead stock in order to minimize costs. This can be done by setting realistic inventory levels, performing regular reviews of inventory levels, and disposing of excess inventory. Doing so can help free up money tied up in dead stock and eliminate overhead costs. This will also help prevent the stock from becoming obsolete and further reducing its value.

- Storage expenses: Having too much dead stock can lead to a decrease in storage space and additional costs associated with storage.

- Staffing expenses: It can also require more time and effort to manage and possibly require more staffing resources.

Overall, dead stock can significantly impact inventory management, and businesses should take the necessary steps to minimize the cost implications.

Efficiency Problems

Dead stock can lead to several efficiency problems in inventory management.

- First, dead stock takes up valuable storage space, which could be better used to store other inventory that is more likely to sell.

- Second, it can tie up capital that could be used to purchase more profitable inventory.

- Third, it can lead to inaccurate inventory tracking since the dead stock is rarely updated in the system.

- Finally, stocking and managing dead stock can be labor-intensive and time-consuming, both of which add to operational costs.

Strategies to Reduce Dead Stock

Dead stock can have serious implications on the well-being of a business. Here are some strategies to combat and keep it in check:

Analyze Your Inventory

Track your sales and inventory data to identify items with low turnover. This will allow you to identify slow-selling items and prioritize them for action.

Here’s how you can proceed with a detailed analysis:

- Analyze Your Sales Data: Analyzing your sales data can help identify trends in customer buying patterns, which can help you adjust your inventory levels accordingly.

- Track Your Returns: Tracking your returns can help you identify which products are not selling and why. This can help you make decisions about which products to discontinue or discount.

- Adjust Your Ordering Process: Adjusting your ordering process can help you minimize dead stock. Consider ordering smaller quantities more frequently so that you can adjust your inventory levels based on demand.

- Utilize Discounts and Promotions: Offering discounts and promotions can help you move dead stock. Consider offering discounts or promotional offers to encourage customers to purchase items sitting in your inventory for too long.

Monitor Supplier Performance

Monitor your suppliers’ performance and stock levels to ensure they are providing you with what you need in a timely manner.

- Set Reasonable Expectations: Make sure you and your suppliers are on the same page. Set reasonable expectations for delivery times and quality of products. Make sure you also communicate any changes in demand promptly to your suppliers so they can adjust accordingly.

- Keep Communication Open: The best way to ensure your suppliers are performing is to maintain a good relationship with them. Regularly communicate with your suppliers and let them know when changes are needed or when there are issues that need to be addressed.

- Monitor Supplier Engagement: Keeping an eye on your suppliers is key to reducing dead stock. Make sure they meet deadlines and deliver the correct number and quality of products. Make sure they are also aware of seasonal or promotional changes that may affect demand.

Improve Forecasting and Planning

Improve forecasting and planning processes to ensure that you only order what you need and do not overstock.

- Establish clear inventory goals: Establish clear target inventory levels for each product or SKU, and review them on a regular basis. Make sure that your goals are realistic and achievable and that you have a plan in place for managing them.

- Utilize data-driven forecasting: Utilize historical data and predictive analytics to create accurate demand forecasts for each product or SKU. This will help you plan better and reduce the risk of overstocking or understocking.

- Automate replenishment: Automate the replenishment process so that inventory is restocked in a timely manner. This will help you avoid stockouts and reduce the need for emergency orders that result in excess inventory.

- Implement inventory optimization: Use inventory optimization techniques such as ABC Analysis and forecasting to identify slow-moving products and make decisions about how much inventory to keep on hand.

- Monitor inventory levels: Monitor inventory levels on a regular basis so you can identify any potential problems early and make the necessary adjustments.

- Review old inventory: Regularly review old inventory and consider selling off excess stock that might be sitting around for too long. This will help to reduce the risk of dead stock.

- Utilize vendors: Consider working with vendors who can help to reduce your inventory levels or provide flexible delivery schedules. This can help to reduce the risk of overstocking.

Adjust Pricing

Adjust the pricing of slow-moving items to make them more attractive to customers.

- Evaluate competitors’ pricing: Compare your dead stock items to those of your competitors. If the price difference is significant, it may be necessary to adjust prices to be more competitive.

- Consider promotional pricing: Consider offering promotional pricing on dead stock items to encourage buyers to purchase them. This could be as simple as offering discounts or bundling items together to create a more attractive offer.

- Adjust your pricing strategy: If the items are not selling despite being competitively priced, it may be necessary to adjust your pricing strategy. Consider reducing prices on dead stock items to move them more quickly and make room for new products.

- Track and measure results: Monitor sales data after making any pricing adjustments to determine whether they have the desired effect. If not, consider other approaches, such as inventory liquidation or donating the items to charity.

Donate or Sell to Discount Retailers

Donate or sell slow-moving stock to discount retailers or charities, often willing to take the stock off your hands for a reduced price. The following steps show how you can accomplish this:

- Reach out to discount retailers: Before you donate or sell to discount retailers, you should contact them to find out their donation or purchase policies. You should also inquire about the types of products they accept, as discount retailers may have specific requirements for items that can be sold or donated.

- Prepare your items: Before donating or selling to discount retailers, give them a thorough clean and repair any damages. This will help improve the probability of your items being accepted by the discount retailer.

- Offer discounts: Discount retailers are selling discounted items, so you may have to offer them a further discount on your products to get them to accept your donation or purchase.

- Provide product information: When you reach out to discount retailers with information about your items, be sure to provide as much information as possible. This includes product images, pricing, and any other relevant details.

- Negotiate: When selling or donating to discount retailers, you may be able to negotiate a better price for your items. Be sure to get all the details of the agreement in writing before you finalize the deal.

Invest in Technology

You can invest in technology that can help track and monitor inventory levels and sales data in real-time. This will aid in reacting quickly to changes in demand.

- Automate Inventory Management: Implementing an automated inventory management system will help you track stock levels in real-time and quickly identify when you have dead stock. Automation can also help you monitor and manage the accuracy of your inventory, reducing the chances of inaccurate stock counts.

- Improve Visibility: Improving your visibility into your inventory levels can help you identify when you have dead stock and give you a better understanding of the causes. You can use analytics to gain insight into customer demand and supply chain operations, helping you adjust your inventory levels to match demand.

- Utilize Predictive Analytics: Predictive analytics can help you forecast customer demand and adjust your inventory levels to match. This will help you reduce stock levels and avoid having too much or too little of an item.

- Invest in RFID Technology: Investing in RFID technology can help you track your inventory in real time and provide you with better visibility into stock levels. You can also use RFID to reduce theft and ensure the accuracy of stock counts.

- Implement Vendor-Managed Inventory: Vendor-managed inventory can help keep your inventory levels accurate and up to date. This will help you reduce dead stock and optimize inventory levels.

Eliminating Dead Stock with Inventory Management Software

Inventory management software can be a great tool for eliminating dead stock. Dead stock is inventory that is held for a long period and has not been sold or used. This can be a costly and inefficient process for businesses.

Inventory management software can help companies identify and eliminate dead stock. It can track inventory levels and sales trends, so businesses can see which items are selling and which ones are not. It can also provide visibility into how long certain items have been in inventory and when they are due to be restocked.

With the right inventory management software, businesses can prevent the buildup of dead stock and keep their inventory levels in check. This can help them save money, optimize storage space, and maintain a healthy inventory to meet customer demand.

Conclusion

Dead stock is an ever-growing problem in the retail industry. There is an estimated $100 billion of dead stock in the retail industry at any given time, and it only continues to increase. This results from overproduction, slow-moving inventory, and improper inventory management.

Dead stock not only leads to financial losses for retailers but also has a negative environmental impact. There are a variety of methods that retailers can use to reduce the amount of dead stock they have. These include increasing data analysis of inventory, utilizing safety stock, and offering discounts to customers.

Additionally, retailers should look into using technology such as radio-frequency identification to increase inventory accuracy. Overall, the dead stock is a significant problem in the retail industry. However, with the right strategies and technologies, retailers can greatly reduce their dead stock and the associated financial losses.

By taking the time to analyze their inventory and implement the proper strategies, retailers can ensure that they are maximizing their profits while reducing their environmental impact.

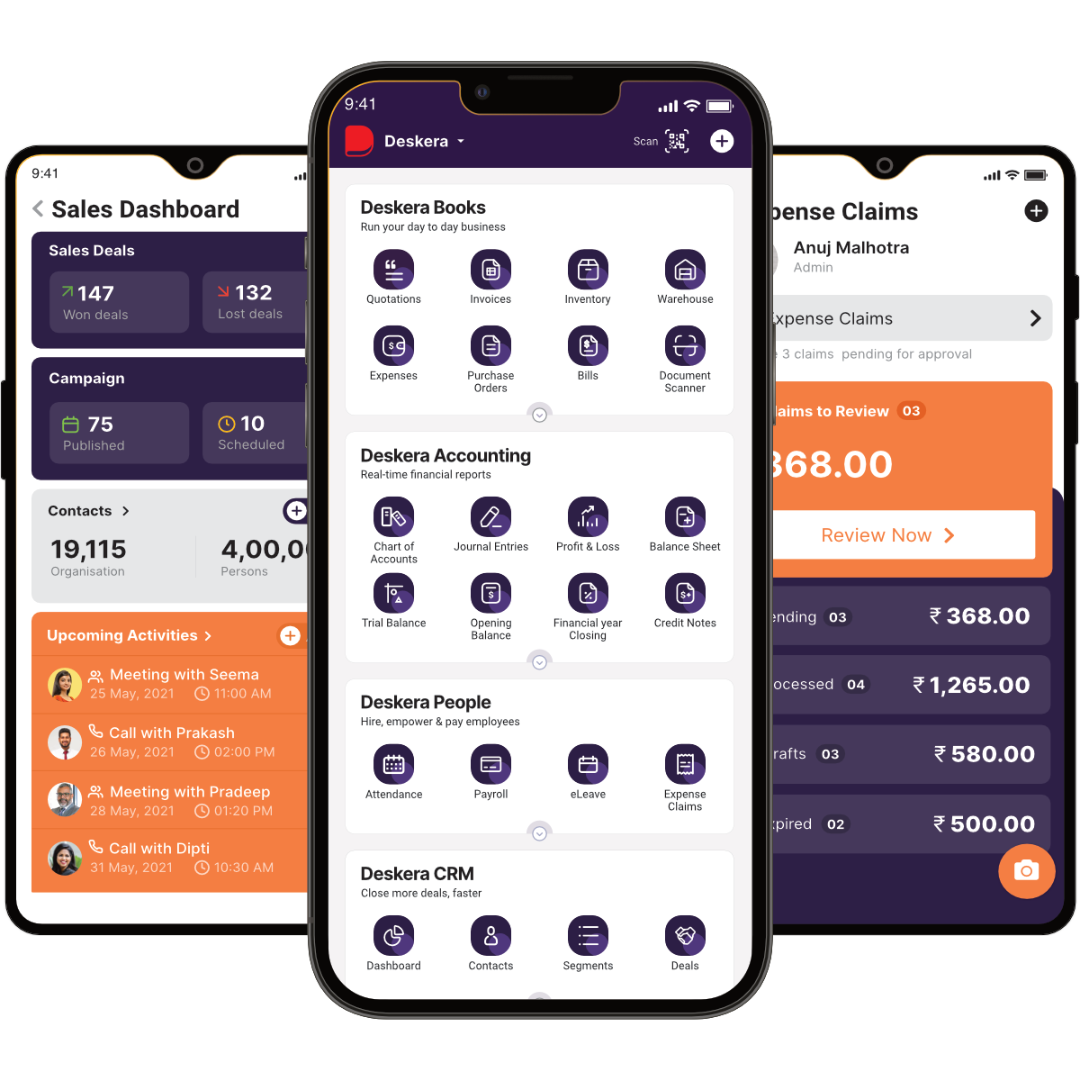

How can Deskera Help You?

Deskera can help prevent dead stock by providing real-time inventory visibility and analytics to enable better decision-making. It allows businesses to track stock movements, inventory levels, and stock forecasts in one place.

Deskera MRP is the one tool that lets you do all of the above. With Deskera, you can:

- Track raw materials and finished goods inventory

- Manage production plans and routings

- Maintain bill of materials

- Generate detailed reports

- Create custom dashboards

Deskera Books is an easy-to-use cloud-based accounting and bookkeeping software that helps small and medium-sized businesses manage their finances more efficiently. It helps businesses streamline their accounting processes, automate bookkeeping tasks, and generate insightful financial reports.

Deskera People is an integrated HR management system that helps you manage your workforce and HR operations. It provides features such as employee profiles, attendance tracking, payroll integration, performance reviews, leave management, and reporting.

Deskera CRM is a cloud-based customer relationship management (CRM) software designed to help businesses streamline their sales and customer management processes.

Key Takeaways

- Dead stock is wrong for a company because it ties up capital and resources that could be used more effectively elsewhere. It also reduces the space available to store new products and can lead to a loss of revenue due to the cost of storing and holding the dead stock.

- Dead stock often represents a large financial loss for companies, as they have spent money producing and stocking the inventory but cannot recover the cost of the goods by selling them.

- To prevent dead stock, keeping a close eye on inventory levels and trends is essential.

- Analyzing sales data can help you identify which products are selling quickly and which are not.

- Just-in-time inventory management is a technique that helps to reduce the amount of inventory held by an organization.

- Automated reordering systems can help to reduce the risk of dead stock by automatically ordering new stock when the existing stock reaches a certain level.

- Offering discounts and promotions on certain items can help reduce the risk of dead stock by encouraging customers to purchase products they may otherwise not be sold.

- To properly manage dead stock, businesses should first identify it. This can be done by running regular inventory reports and analyzing them to find items that have not sold in a certain period (usually several months).

- Clearance sales, donating, and disposing of are some of the ways in which you can deal with dead stock.

- Poor inventory management can lead to dead stock, as companies may not have the right systems in place to accurately track and monitor their stock levels.

- Companies may hold too much stock, which can lead to dead stock.

- Outdated stock can quickly become dead stock if companies don't actively monitor and adjust their inventory levels to reflect demand.

- Unforeseen events, such as a natural disaster or sudden changes in market trends, can lead to dead stock if companies don't have the means to quickly adjust their stock levels in response.

- Companies may not accurately forecast their future demand, leading to an excess of stock that can't be sold in time.

- Poor product quality can lead to customer dissatisfaction and make it more difficult to sell the product. If a company is unable to meet customer expectations due to poor quality, it can lead to an excess of unsold inventory.

- Dead stock can result in cost implications and efficiency problems.

- Analyzing inventory, monitoring supplier’s performance, and adjusting pricing are some of the methods adopted to manage dead stock.

Related Articles