In order to ensure the smooth running of your business, you need to be able to measure and monitor order management performance. But measuring order management performance can be a daunting task, especially if you are not familiar with the various metrics that are available.

Order management performance has a significant impact on the efficiency of your business. It determines how well your customers are being served and whether inventory is being moved correctly. There are a number of important metrics that you need to track in order to improve your order management performance.

If you want to achieve optimal order management performance, you need to use the right metrics. You need to evaluate customer satisfaction, order fulfillment time, inventory levels, and other factors. By knowing what these numbers mean and how they relate to each other, you can identify areas for improvement and make necessary changes.

In today’s guide, we’ll thoroughly learn about 9 important metrics for evaluating order management performance. Let’s take a look at the table of content below:

- What is Order Management?

- Order Management Performance

- 9 Crucial Metrics for Evaluating Order Management System

- How You Can Improve Order Management Metrics?

- Important Benefits of Tracking Order Management Performance Metrics

- Frequently Asked Questions (FAQs) Associated with Order Management Performance Metrics

- Wrapping Up

- How Deskera Can Assist You?

Let's get started!

What is Order Management?

Order management refers to the process of efficiently and effectively handling customer orders from the point of initiation to fulfillment and beyond. It involves the coordination and execution of various activities, such as order processing, inventory management, logistics, and customer service, to ensure that orders are accurately and promptly fulfilled while meeting customer expectations.

The order management process typically includes the following key steps:

Order Placement: Customers place orders through various channels, such as online platforms, phone calls, or in-person interactions. The order information, including product details, quantities, and customer preferences, is collected and recorded.

Order Processing: Once an order is received, it undergoes processing, which involves verifying the order details, checking product availability, and determining pricing, discounts, and promotions. This step may also involve order validation, such as fraud checks and credit verification.

Inventory Management: During order processing, the availability of products is checked against the inventory. Inventory levels need to be accurately tracked to ensure that the requested products are in stock and can be fulfilled. In cases where products are out of stock, appropriate actions such as backorders or alternative product suggestions may be considered.

Order Fulfillment: After order processing and inventory confirmation, the order moves to the fulfillment stage. This involves picking the ordered items from the inventory, packaging them securely, and preparing them for shipment or delivery. Fulfillment can be handled internally or outsourced to third-party logistics providers.

Shipping and Delivery: Once the order is packaged, it is shipped through a chosen carrier or delivery service. Tracking information is provided to the customer, allowing them to monitor the progress of their shipment. Timely and reliable delivery is crucial for customer satisfaction.

Order Tracking and Customer Communication: Throughout the order management process, proactive communication with customers is essential. Order tracking updates, including shipping status and estimated delivery dates, should be provided to keep customers informed. This helps manage customer expectations and enables them to plan accordingly.

Order Returns and Exchanges: Handling returns and exchanges are an integral part of order management. When customers wish to return or exchange a product, a streamlined process should be in place to handle such requests efficiently. This includes managing return authorization, processing refunds or replacements, and ensuring proper inventory management for returned items.

Order Analytics and Performance Measurement: To continuously improve order management processes, businesses need to track and analyze relevant data and performance metrics. This includes monitoring key metrics like order cycle time, order accuracy, inventory turnover, and customer satisfaction. These insights can help identify bottlenecks, optimize inventory levels, improve fulfillment efficiency, and enhance overall customer experience.

Effective order management enables businesses to streamline operations, reduce costs, improve customer satisfaction, and maintain healthy inventory levels. By optimizing the order management process, businesses can enhance their competitiveness, strengthen customer relationships, and drive growth in the long run.

Order Management Performance

Order management performance refers to the effectiveness and efficiency with which an organization manages its orders throughout the entire order lifecycle, from placement to fulfillment and beyond. It encompasses various aspects of order processing, inventory management, fulfillment, and customer service.

Furthermore, evaluating and improving order management performance is crucial for businesses to meet customer expectations, reduce costs, and optimize operational efficiency.

9 Crucial Metrics for Evaluating Order Management System

Following, we key components that contribute to order management performance:

Cost per Order

Cost per Order (CPO) is a financial metric that measures the average cost incurred by a business to process and fulfill a single order. It provides insights into the efficiency and cost-effectiveness of the order management process.

Calculating and monitoring the Cost per Order helps businesses identify areas of cost optimization and improve profitability. Here is a detailed explanation of the Cost per Order:

Calculation of Cost per Order:

To calculate the Cost per Order, you need to consider the direct and indirect costs associated with order processing. Here are the key cost components to include in the calculation:

Direct Costs:

a. Labor Costs: Calculate the labor costs associated with order processing, including wages, salaries, and benefits of employees involved in order entry, verification, picking, packing, and shipping.

b. Material Costs: Include the costs of packaging materials, shipping labels, invoices, and any other physical materials used in the order fulfillment process.

c. Shipping Costs: Consider the costs associated with shipping the order to the customer, including shipping fees, packaging, and handling charges.

Indirect Costs:

a. Overhead Costs: Allocate a portion of the overhead costs related to order management, such as rent, utilities, equipment, and maintenance expenses. Divide these costs by the total number of orders to determine the share per order.

b. Technology Costs: Include the costs associated with order management software, order tracking systems, and other technology tools used in the order placement process.

c. Customer Service Costs: Consider the costs of customer service support related to order inquiries, changes, and issue resolution.

Once you have collected the relevant cost data, calculate the total cost incurred for a specific period (e.g., monthly or annually) and divide it by the total number of orders processed during that period.

Interpreting Cost per Order:

A higher Cost per Order indicates higher expenses incurred to process and fulfill each order. It may be a result of inefficient processes, excessive labor or material costs, or suboptimal utilization of resources. Conversely, a lower Cost per Order indicates more efficient operations and cost-effective order processing.

Strategies for Minimizing Cost per Order:

Process Automation: Implement order management systems and automation tools to streamline order processing. Automating repetitive tasks, such as order entry, verification, and inventory management, reduces manual labor costs and improves overall efficiency.

Supply Chain Optimization: Optimize your supply chain to minimize shipping and transportation costs. Negotiate better rates with shipping providers, consolidate orders, and optimize packaging to reduce material and shipping expenses.

Efficient Inventory Management: Implement effective inventory management practices to avoid overstocking or stockouts. Accurate demand forecasting, just-in-time inventory, and effective inventory control can minimize carrying costs and reduce wastage.

Workflow Analysis: Conduct a thorough analysis of your order management process to identify bottlenecks and areas for improvement. Streamline workflows, eliminate redundant steps, and reduce error rates to optimize efficiency and reduce costs.

Employee Training: Invest in training and development programs for your staff to improve their productivity and accuracy. Well-trained employees can process orders more efficiently, reducing the overall cost per order.

Vendor Negotiation: Negotiate favorable terms and pricing with suppliers and vendors. Bulk purchasing, volume discounts, and strategic partnerships can help lower material costs and improve cost per order.

Technology Investment: Continuously evaluate and invest in technologies that can improve order management efficiency. Implementing advanced order management systems, inventory tracking tools, and customer relationship management (CRM) software can streamline processes and reduce costs.

Continuous Improvement: Foster a culture of continuous improvement by regularly reviewing and analyzing cost-per-order data. Set performance targets, track progress, and implement cost-saving initiatives based on data-driven insights.

By consistently monitoring and optimizing the Cost per Order, businesses can improve operational efficiency, reduce costs, and enhance profitability while maintaining customer satisfaction and order accuracy.

Internal Order Cycle Time

Internal Order Cycle Time refers to the duration it takes for an order to be processed and fulfilled within an organization. It encompasses all the internal processes involved, from the time an order is received until it is ready for shipment or delivery. Monitoring and optimizing the internal order cycle time is essential for improving operational efficiency, customer satisfaction, and overall business performance.

The formula to calculate the Internal Order Cycle Time is as follows:

To calculate the Internal Order Cycle Time, subtract the date and time the order was placed from the date and time the order was shipped. The result will be the duration or time taken for the order to move through the internal processes and be ready for shipment.

Note: It's important to ensure that the time and date values are in a consistent format and timezone to obtain an accurate calculation.

Here is a detailed explanation of Internal Order Cycle Time:

Order Processing:

Order processing involves activities such as order entry, verification, and validation of customer information, product selection, and pricing. It also includes any necessary approvals or authorizations before moving forward with order fulfillment. Efficient and accurate order processing is crucial to ensure the smooth flow of orders through the internal systems.

Inventory Allocation:

Once an order is processed, the next step is to allocate inventory for the order. This involves checking the availability of products, updating inventory records, and reserving the necessary items. Efficient inventory allocation ensures that products are ready for fulfillment and minimizes the risk of stockouts or delays.

Order Fulfillment:

Order fulfillment encompasses picking, packing, and preparing orders for shipment or delivery. It involves locating the products in the warehouse, verifying the order details, packaging the items securely, and generating necessary documentation, such as shipping labels and invoices. Furthermore, streamlining the order fulfillment process helps ensure accuracy and efficiency in preparing orders for the next stage.

Quality Control and Inspection:

Before an order is shipped or delivered to the customer, it should undergo quality control and inspection processes. This step involves checking for product defects, verifying order accuracy, and ensuring that the items meet the required quality standards. Thorough quality control helps reduce the risk of shipping incorrect or defective products to customers.

Shipping and Delivery Preparation:

Once the order has passed the quality control stage, it is prepared for shipping or delivery. This involves coordinating with logistics providers, arranging transportation, and generating shipping documents. The order is then handed over to the shipping carrier or prepared for internal delivery. Efficient shipping and delivery preparation help ensure timely and accurate order delivery.

Order Tracking and Customer Communication:

Throughout the internal order cycle, it is crucial to track the status of orders and maintain open communication with customers. Providing order tracking information, updates on order progress, and addressing customer inquiries or concerns help enhance customer satisfaction and manage expectations.

Monitoring and Optimizing Internal Order Cycle Time:

Establish Baseline Metrics: Start by measuring and documenting the current internal order cycle time. Capture data on each stage of the process, including the time taken at each step, any bottlenecks or delays encountered, and the overall time from order receipt to order fulfillment.

Identify Bottlenecks and Inefficiencies: Analyze the data collected to identify areas of inefficiency or bottlenecks in the internal order cycle. Look for recurring issues, delays, or unnecessary steps that can be optimized or eliminated to streamline the process.

Process Automation and Standardization: Implement technology solutions and automation tools to streamline manual tasks and standardize processes. Automation can help reduce human error, improve speed and accuracy, and free up resources for more value-added activities.

Workflow Optimization: Review the sequence and flow of activities within the internal order cycle. Identify opportunities for process reengineering or optimization to eliminate unnecessary steps, consolidate tasks, or parallelize activities to reduce overall cycle time.

Integration and Collaboration: Foster collaboration and integration between departments involved in the order management process. Improve communication and information sharing to ensure smooth handoffs between teams and minimize delays caused by miscommunication or coordination issues.

Employee Training and Development: Invest in training programs to enhance employee skills and knowledge. Well-trained and competent staff can perform tasks more efficiently, reducing cycle time and improving overall productivity.

Performance Monitoring and Continuous Improvement: Continuously monitor internal order cycle time metrics to assess the effectiveness of implemented changes. Set performance targets, track progress, and implement ongoing improvements based on data-driven insights and customer feedback.

By monitoring and optimizing the internal order cycle time, businesses can improve operational efficiency, reduce order processing delays, enhance customer satisfaction, and ultimately drive overall business success.

Order Fulfilment Cycle Time

Order Fulfillment Cycle Time refers to the duration it takes for an order to be processed and delivered to the customer. It includes all the steps involved, from the time an order is received until it is successfully delivered. Calculating the Order Fulfillment Cycle Time helps businesses assess their efficiency in fulfilling customer orders and identify areas for improvement. Here is the formula and a detailed explanation of the Order Fulfillment Cycle Time:

The formula for Order Fulfillment Cycle Time:

The Order Fulfillment Cycle Time is obtained by subtracting the date and time the order was placed from the date and time the order was delivered to the customer.

Explanation of Order Fulfillment Cycle Time:

Time & Date Order Placed: This refers to the date and time when the customer placed the order. It marks the beginning of the order fulfillment process.

Time & Date Order Delivered: This represents the date and time when the order is successfully delivered to the customer. It marks the end of the order fulfillment process.

Calculating the Order Fulfillment Cycle Time by subtracting the time and date the order was placed from the time and date the order was delivered provides the duration it took to fulfill the order.

Interpreting Order Fulfillment Cycle Time:

The Order Fulfillment Cycle Time represents the overall time it took for the order to be processed, prepared, and delivered to the customer. A shorter Order Fulfillment Cycle Time generally indicates more efficient operations and faster delivery. However, it is important to note that the desired cycle time may vary based on industry standards, customer expectations, and the type of products being fulfilled.

Strategies for Optimizing Order Fulfillment Cycle Time:

Streamline Order Processing: Optimize the order processing steps, such as order entry, verification, and validation, to minimize delays and errors. Automate routine tasks and implement efficient order management systems to expedite the process.

Efficient Inventory Management: Maintain accurate inventory records and implement effective inventory management practices. Ensure that products are readily available for order fulfillment, minimizing delays caused by stockouts or replenishment issues.

Streamlined Order Fulfillment Process: Evaluate and streamline the order fulfillment process, including picking, packing, and shipping. Eliminate unnecessary steps, optimize workflows, and utilize technology to improve speed and accuracy.

Collaborate with Suppliers: Build strong relationships with suppliers to ensure timely and reliable product availability. Collaborate closely to address potential supply chain bottlenecks and reduce lead times.

Optimized Shipping and Logistics: Evaluate shipping options, carrier performance, and logistics processes to optimize delivery speed and accuracy. Utilize real-time tracking systems and efficient shipping methods to provide timely updates to customers.

Continuous Improvement: Continuously monitor Order Fulfillment Cycle Time and analyze the data to identify areas for improvement. Use customer feedback and performance metrics to drive continuous improvement initiatives and enhance order fulfillment efficiency.

By optimizing the Order Fulfillment Cycle Time, businesses can enhance customer satisfaction, increase operational efficiency, and maintain a competitive edge in the marketplace.

On-time Shipping Rate

On-time Shipping Rate is a metric that measures the percentage of orders shipped and delivered to customers within the promised timeframe. It indicates the reliability and efficiency of the shipping process in meeting customer expectations.

The formula for calculating the On-time Shipping Rate is as follows:

To calculate the On-time Shipping Rate, divide the number of orders that were shipped and delivered on time by the total number of orders shipped, and then multiply by 100 to express it as a percentage.

Explanation of On-time Shipping Rate:

Number of Orders Shipped on Time: This refers to the count of orders that were shipped and delivered to customers within the promised timeframe. These are orders where the shipping process was completed and the products reached the customers as expected, without any delay.

Total Number of Orders Shipped: This represents the overall count of orders that were shipped during the specified period. It includes all orders shipped, regardless of whether they were delivered on time or experienced delays.

Calculating the On-time Shipping Rate by dividing the number of orders shipped on time by the total number of orders shipped provides the percentage of orders that were successfully delivered within the promised timeframe.

Interpreting On-time Shipping Rate:

The On-time Shipping Rate indicates the proportion of orders that were delivered to customers as promised. A higher On-time Shipping Rate signifies a more reliable and efficient shipping process, which contributes to customer satisfaction and builds trust. It demonstrates a business's ability to meet delivery commitments and fulfill customer expectations.

Strategies for Improving On-time Shipping Rate:

Accurate Order Processing: Ensure accurate and timely order processing, including order verification, inventory allocation, and picking. Streamline the order management process to minimize errors and delays in initiating the shipping process.

Efficient Warehouse Operations: Optimize warehouse operations to expedite order fulfillment. Implement efficient picking, packing, and labeling processes to minimize processing time and improve overall shipping speed.

Inventory Visibility and Management: Maintain accurate and real-time inventory visibility to prevent stockouts and ensure product availability for timely shipping. Implement inventory management systems to monitor stock levels, track replenishment needs, and avoid delays caused by insufficient inventory.

Effective Logistics and Carrier Selection: Choose reliable logistics partners and carriers known for their on-time delivery performance. Evaluate their track record, transit times, and service quality to ensure timely and efficient shipping.

Streamlined Order Handoff: Establish effective communication channels and processes between order processing, fulfillment, and shipping teams. Streamline the handoff of orders from one department to another to minimize delays and miscommunications.

Proactive Shipment Tracking: Implement shipment tracking systems and provide customers with tracking information. Proactively communicate shipping updates and potential delays to customers, allowing them to stay informed and manage their expectations.

Continuous Improvement: Regularly monitor and analyze shipping performance metrics, including On-time Shipping Rate. Identify trends, root causes of delays, and areas for improvement. Implement corrective actions, process enhancements, and employee training to continually improve shipping efficiency and reliability.

By improving the On-time Shipping Rate, businesses can enhance customer satisfaction, increase trust, and maintain strong customer relationships. Timely and reliable shipping contributes to positive customer experiences and strengthens the overall reputation of the business.

Purchasing Frequency

Purchasing Frequency is a metric that measures how often customers make purchases within a specific time period. It provides insights into customer behavior, loyalty, and engagement with a business.

The formula for calculating Purchasing Frequency is as follows:

To calculate the Purchasing Frequency, divide the total number of purchases made within a specific time period by the number of unique customers who made those purchases.

Explanation of Purchasing Frequency:

Total Number of Purchases: This represents the count of all purchases made by customers within the specified time period. It includes repeat purchases made by the same customer.

Number of Unique Customers: This refers to the count of distinct or unique customers who made purchases during the same time period. It excludes repeat customers to avoid double-counting.

Calculating the Purchasing Frequency by dividing the total number of purchases by the number of unique customers provides the average number of purchases per customer within the specified time period.

Interpreting Purchasing Frequency:

Purchasing Frequency indicates how often, on average, customers make purchases. A higher Purchasing Frequency suggests higher customer engagement, loyalty, and a stronger relationship with the business. Furthermore, it demonstrates that customers are more likely to make repeat purchases and have a higher propensity to engage with the brand.

Strategies to Increase Purchasing Frequency:

Customer Segmentation and Personalization: Segment customers based on their preferences, behaviors, and purchase history. Use personalized marketing strategies to encourage repeat purchases and engage customers with relevant offers or recommendations.

Loyalty Programs: Implement a loyalty program that rewards customers for their repeat purchases. Offer incentives, discounts, or exclusive perks to encourage customers to make more frequent purchases and foster a sense of loyalty.

Email Marketing and Remarketing: Utilize email marketing campaigns to stay top-of-mind with customers and remind them of new products, promotions, or exclusive offers. Use remarketing techniques to reach out to customers who have shown interest but have not made a recent purchase.

Upselling and Cross-selling: Encourage customers to add complementary products to their orders through upselling and cross-selling strategies. Recommend related or upgraded items during the purchasing process to increase the average order value and potentially trigger more frequent purchases.

Proactive Customer Support: Provide excellent customer service and support to enhance the overall customer experience. Address customer inquiries promptly, resolve issues efficiently, and build trust and loyalty, leading to increased purchasing frequency.

Exclusive Events and Promotions: Organize special events, flash sales, or limited-time promotions to create a sense of urgency and encourage customers to make more frequent purchases. Exclusive offers for loyal customers can drive repeat business and increase their purchasing frequency.

Continuous Improvement and Analysis: Regularly analyze customer data, purchase patterns, and feedback to identify trends, preferences, and areas for improvement. Use data-driven insights to refine marketing strategies, product offerings, and overall customer experience to drive increased purchasing frequency.

By focusing on strategies to increase Purchasing Frequency, businesses can drive customer loyalty, increase revenue, and build a strong customer base that engages with the brand more frequently.

Average Order Value (AOV)

Average Order Value (AOV) is a metric that measures the average monetary value of each customer's order. It provides insights into customer spending habits and helps businesses understand the value and profitability of their orders.

The formula for calculating Average Order Value is as follows:

To calculate the Average Order Value, divide the total revenue generated within a specific time period by the total number of orders placed during that same time period.

Explanation of Average Order Value:

Total Revenue: This represents the sum of all revenue generated from customer orders within the specified time period. It includes the total monetary value of all products or services sold.

Total Number of Orders: This refers to the count of all orders placed by customers during the same time period. It includes both unique and repeat orders.

Calculating the Average Order Value by dividing the total revenue by the total number of orders provides the average monetary value of each customer's order within the specified time period.

Interpreting Average Order Value:

The Average Order Value indicates the typical amount of money customers spend per order. A higher Average Order Value suggests that customers tend to spend more with each transaction, which can lead to increased revenue and profitability. It helps businesses assess their pricing strategy, cross-selling or upselling effectiveness, and overall customer spending patterns.

Strategies to Increase Average Order Value:

Cross-selling and Upselling: Recommend additional or complementary products to customers during the purchasing process. Highlight related items, upgrades, or bundles that can enhance the customer's order and increase the total order value.

Volume Discounts and Bundles: Offer discounts or incentives for customers who purchase larger quantities or opt for bundled packages. Encourage customers to increase their order size to take advantage of cost savings or additional value.

Free Shipping Thresholds: Set a minimum order value for free shipping. This incentivizes customers to add more items to their cart to reach the threshold, increasing the average order value.

Loyalty Programs and Incentives: Implement loyalty programs that reward customers for reaching specific spending milestones or making repeat purchases. Offer exclusive discounts, rewards, or early access to new products to incentivize customers to increase their order value.

Personalized Recommendations: Leverage customer data and purchase history to provide personalized product recommendations. Use algorithms or machine learning to suggest relevant items that align with customer preferences, driving higher order value through personalized recommendations.

Limited-time Offers and Upsell Promotions: Create limited-time offers or promotions that encourage customers to upgrade their purchase or add higher-value items to their order. Highlight the value proposition and time sensitivity to drive increased spending.

Product Bundling and Cross-category Promotion: Bundle complementary products or promote cross-category purchases to encourage customers to explore and buy from different product lines. This can lead to higher order values by enticing customers to purchase items they may not have considered initially.

Enhanced Customer Experience: Provide exceptional customer service and support throughout the purchasing process. Respond to customer inquiries promptly, offer personalized assistance, and ensure a smooth and enjoyable customer journey. Satisfied customers are more likely to make larger purchases.

By implementing strategies to increase Average Order Value, businesses can boost their revenue, maximize customer spending, and improve overall profitability. Continuous monitoring and analysis of AOV can help identify trends, measure the impact of pricing or promotional strategies, and refine tactics to drive increased order values.

Order Picking Accuracy

Order Picking Accuracy is a metric that measures the percentage of orders that are picked and fulfilled accurately without any errors or discrepancies. It reflects the precision and reliability of the order fulfillment process.

The formula for calculating Order Picking Accuracy is as follows:

To calculate the Order Picking Accuracy, divide the number of orders that were picked and fulfilled accurately by the total number of orders that were picked, and then multiply by 100 to express it as a percentage.

Explanation of Order Picking Accuracy:

Number of Orders Picked and Fulfilled Accurately: This refers to the count of orders that were picked and fulfilled with no errors or discrepancies. These orders were accurately packed and contained all the correct items, quantities, and specifications as requested by the customer.

Total Number of Orders Picked: This represents the overall count of orders that were picked for fulfillment. It includes all orders that were prepared for shipment, regardless of whether they had errors or discrepancies.

Calculating the Order Picking Accuracy by dividing the number of accurately picked and fulfilled orders by the total number of orders picked provides the percentage of orders that were successfully fulfilled without errors.

Interpreting Order Picking Accuracy:

Order Picking Accuracy indicates the level of precision and reliability in the order fulfillment process. A higher Order Picking Accuracy implies that the fulfillment team consistently picks and packs orders accurately, minimizing errors and discrepancies. This contributes to customer satisfaction, reduces returns or exchanges, and helps maintain a positive brand reputation.

Strategies to Improve Order Picking Accuracy:

Adequate Training: Provide comprehensive training to warehouse personnel involved in the order-picking process. Ensure they understand the correct procedures, product identification, handling, and packaging requirements to minimize errors.

Standardized Processes: Implement standardized picking procedures, including clear guidelines for order verification, item identification, and packaging. Establish checklists, visual aids, or barcode scanning systems to assist in accurate order picking.

Quality Control Checks: Incorporate quality control checks at various stages of the picking process to verify accuracy. Conduct random checks, sample inspections, or utilize technology-based scanning systems to ensure the correct items are picked.

Efficient Warehouse Layout: Organize the warehouse layout in a logical and efficient manner. Group products by category or popularity to minimize confusion and reduce the risk of picking errors.

Order Verification and Double-Checking: Implement a two-person verification process or utilize technology-based systems for order verification. Have a separate team member cross-check the picked items against the order details to ensure accuracy before packaging.

Technology Integration: Utilize technology solutions, such as barcode scanning systems or warehouse management systems (WMS), to automate and streamline the picking process. These systems can help reduce human error, improve accuracy, and provide real-time inventory visibility.

Continuous Improvement: Regularly review and analyze picking accuracy metrics. Identify patterns, root causes of errors, and areas for improvement. Implement corrective actions, process enhancements, and employee training to continually improve picking accuracy.

By focusing on improving Order Picking Accuracy, businesses can enhance operational efficiency, reduce order errors, improve customer satisfaction, and maintain a high level of order fulfillment accuracy

Rate of Returns

Rate of Returns, also known as Return Rate or Return Percentage, is a metric that measures the percentage of orders or products that are returned by customers. It provides insights into customer satisfaction, product quality, and the effectiveness of the order fulfillment process.

The formula for calculating the Rate of Returns is as follows:

To calculate the Rate of Returns, divide the number of returned orders by the total number of orders, and then multiply by 100 to express it as a percentage.

Explanation of Rate of Returns:

Number of Returned Orders: This refers to the count of orders that are returned by customers due to various reasons, such as product defects, incorrect orders, dissatisfaction with the product, or any other issues.

Total Number of Orders: This represents the overall count of orders placed within the specified time period or for a specific product. It includes all orders, regardless of whether they were returned or not.

Calculating the Rate of Returns by dividing the number of returned orders by the total number of orders provides the percentage of orders that were returned.

Interpreting Rate of Returns:

The rate of Returns indicates the proportion of orders that were returned by customers. A higher Rate of Returns suggests potential issues with product quality, inaccurate order fulfillment, or customer dissatisfaction.

Furthermore, monitoring and analyzing this metric helps businesses identify areas for improvement and take corrective actions to reduce returns, enhance customer satisfaction, and improve overall operational efficiency.

Strategies to Minimize Rate of Returns:

Quality Assurance: Implement stringent quality control measures to ensure that products meet or exceed customer expectations. Conduct thorough inspections, testing, and product validation processes to minimize defects and improve product quality.

Accurate Order Fulfillment: Enhance order fulfillment processes to ensure accurate picking, packing, and shipping. Double-check orders for accuracy and completeness to minimize incorrect shipments or missing items.

Clear and Accurate Product Information: Provide detailed and accurate product information, including descriptions, specifications, sizing guides, and images. This helps set proper customer expectations and reduces the likelihood of returns due to inaccurate product information.

Customer Support and Communication: Offer responsive and effective customer support channels to address customer inquiries, concerns, and issues promptly. Clear communication can help resolve problems, prevent returns, and improve customer satisfaction.

Product Reviews and Feedback: Encourage customers to provide product reviews and feedback. This information can help identify potential issues, address product-related concerns, and make necessary improvements to reduce returns.

Transparent Return Policy: Establish a clear and customer-friendly return policy that provides ease of return, exchange, or refund. Transparent policies create trust and confidence in the purchasing process, reducing the likelihood of returns due to complicated or unclear return procedures.

Product Education and Usage Guidelines: Provide comprehensive product education, usage guidelines, and instructions to customers. Clear instructions on product assembly, usage, and maintenance can reduce returns caused by customer errors or misunderstandings.

Continuous Improvement: Continuously analyze return data, identify patterns, and root causes of returns. Use this information to implement corrective actions, such as product improvements, process enhancements, or training programs, to minimize returns and improve overall customer satisfaction.

By focusing on strategies to minimize the Rate of Returns, businesses can reduce operational costs, enhance customer satisfaction, and improve overall profitability. Continuous monitoring and analysis of return data can help identify trends, implement necessary improvements, and enhance the overall customer experience.

Perfect Order Rate

Perfect Order Rate (POR) is a metric that measures the percentage of orders that are fulfilled without any errors or issues across various aspects, including order accuracy, on-time delivery, complete shipment, and proper documentation. It reflects the overall efficiency and effectiveness of the order management and fulfillment processes.

The formula for calculating Perfect Order Rate is as follows:

To calculate the Perfect Order Rate, divide the number of orders that meet all the criteria for a perfect order by the total number of orders, and then multiply by 100 to express it as a percentage.

Explanation of Perfect Order Rate:

Number of Perfect Orders: This refers to the count of orders that are fulfilled without any errors or issues across various criteria. These criteria typically include order accuracy, on-time delivery, complete shipment, proper documentation, and any other specific requirements defined by the business.

Total Number of Orders: This represents the overall count of orders placed within the specified time period or for a specific product. It includes all orders, regardless of whether they meet the criteria for a perfect order.

Calculating the Perfect Order Rate by dividing the number of perfect orders by the total number of orders provides the percentage of orders that meet all the defined criteria for a perfect order.

Interpreting Perfect Order Rate:

Perfect Order Rate reflects the level of accuracy and efficiency in the order fulfillment process. A higher Perfect Order Rate indicates that the majority of orders are fulfilled without any errors or issues, leading to higher customer satisfaction, increased operational efficiency, and improved overall business performance.

Strategies to Improve Perfect Order Rate:

Accurate Order Processing: Implement rigorous order verification and validation processes to ensure accuracy in order entry, pricing, and customer information. Regularly review and update order management systems to reduce errors and improve data accuracy.

Efficient Inventory Management: Optimize inventory management practices to minimize stockouts and ensure product availability for timely fulfillment. Accurate inventory tracking and real-time visibility can help avoid situations where items are missing or unavailable for order fulfillment.

Robust Quality Control: Incorporate quality control checks at various stages of the order fulfillment process. Conduct thorough inspections, testing, and verification processes to minimize errors and ensure the delivery of high-quality products to customers.

Streamlined Order Fulfillment: Analyze and optimize order fulfillment workflows, including picking, packing, and shipping processes. Implement efficient systems, tools, and technologies to enhance speed, accuracy, and overall efficiency.

Effective Communication: Establish clear and effective communication channels between departments involved in the order fulfillment process, such as order processing, inventory management, and logistics. Efficient communication helps prevent errors, address issues promptly, and ensure smooth handoffs between teams.

Continuous Improvement: Regularly monitor and analyze order-related metrics, including order accuracy, on-time delivery, and customer feedback. Use this data to identify areas for improvement, implement corrective actions, and drive continuous process enhancements.

Customer Feedback and Surveys: Collect customer feedback to identify pain points and areas for improvement in the order fulfillment process. Implement post-order surveys or feedback mechanisms to gain insights into customer satisfaction levels and areas where the perfect order criteria can be further refined.

By focusing on strategies to improve the Perfect Order Rate, businesses can enhance customer satisfaction, improve operational efficiency, and strengthen their reputation for delivering accurate and error-free orders. Continuous monitoring, analysis, and improvement of the order fulfillment process contribute to achieving higher Perfect Order Rates and driving overall business success.

How You Can Improve Order Management Metrics?

Improving order management metrics is crucial for enhancing operational efficiency, customer satisfaction, and overall business performance. Here are some detailed strategies to improve key order management metrics:

Order Cycle Time:

- Streamline order processing: Implement automated systems and standardized procedures to reduce manual errors and expedite order processing.

- Improve inventory management: Optimize inventory levels to ensure products are readily available, reducing delays caused by stockouts.

- Enhance communication and collaboration: Foster clear communication channels between departments involved in the order management process to minimize delays and streamline workflows.

Order Accuracy:

- Robust quality control: Implement rigorous quality checks at each stage of order fulfillment to minimize errors and discrepancies.

- Invest in training and development: Provide comprehensive training to employees on order processing, product knowledge, and accuracy in fulfilling customer requests.

- Utilize technology solutions: Implement barcode scanning systems or automated order management systems to improve accuracy and minimize manual errors.

Inventory Turnover:

- Optimize inventory management: Utilize inventory forecasting tools to ensure optimal stock levels, minimize excess inventory, and improve turnover.

- Analyze demand patterns: Conduct regular analysis of customer demand to identify trends and adjust inventory levels accordingly.

- Develop relationships with suppliers: Collaborate with suppliers to reduce lead times, ensure timely replenishment, and minimize stockouts.

Stockout Rate:

- Improve demand forecasting: Utilize historical data, market trends, and customer insights to forecast demand accurately and avoid stockouts.

- Establish safety stock levels: Maintain safety stock to buffer against unexpected fluctuations in demand or delays in replenishment.

- Utilize real-time inventory tracking: Implement systems that provide real-time visibility into inventory levels to proactively address potential stockouts.

On-Time Delivery:

- Efficient logistics management: Optimize transportation and logistics processes to minimize delays and ensure timely delivery.

- Track shipments: Utilize tracking systems to monitor shipments and proactively address any potential issues or delays.

- Collaborate with carriers: Develop strong partnerships with reliable carriers to ensure on-time delivery and effective communication.

Order Fill Rate:

- Improve demand forecasting: Accurately forecast customer demand to ensure sufficient stock availability and minimize backorders.

- Optimize inventory management: Implement just-in-time inventory strategies to ensure products are available for order fulfillment.

- Monitor and address backorders: Regularly monitor backorders and proactively communicate with customers to manage expectations and minimize delays.

Order Return Rate:

- Enhance product information: Provide detailed and accurate product descriptions, specifications, and sizing charts to reduce returns caused by customer dissatisfaction or misunderstandings.

- Improve quality control: Implement rigorous quality checks to reduce the likelihood of defective or damaged products being shipped.

- Optimize packaging: Utilize appropriate packaging materials and methods to ensure products arrive in optimal condition and reduce return rates.

Customer Complaints:

- Implement a customer feedback system: Provide multiple channels for customers to express their concerns and feedback, allowing timely resolution and improvement.

- Monitor and analyze complaints: Regularly review and analyze customer complaints to identify recurring issues and implement appropriate solutions.

- Enhance customer service: Train customer service representatives to handle complaints professionally and provide satisfactory resolutions to customers.

- Continuous monitoring, analysis, and improvement of order management processes are essential for achieving better metrics. Implementing these strategies will lead to improved efficiency, customer satisfaction, and ultimately, business success.

Important Benefits of Tracking Order Management Performance Metrics

Tracking order management performance metrics offers several key benefits for businesses. Here are the main benefits of tracking order management performance metrics:

Improved Operational Efficiency: By tracking metrics such as order cycle time, order accuracy, and inventory turnover, businesses can identify inefficiencies in their order management processes. This enables them to streamline operations, reduce errors, and optimize resource allocation, resulting in improved overall operational efficiency.

Enhanced Customer Satisfaction: Order management performance metrics provide insights into customer-centric factors such as on-time delivery, order fill rate, and order accuracy. By monitoring and improving these metrics, businesses can ensure timely and accurate order fulfillment, leading to higher customer satisfaction levels and improved customer loyalty.

Increased Cost Savings: Tracking metrics like cost per order and return rate allows businesses to identify areas of cost inefficiencies within their order management processes. By pinpointing the root causes of high costs, businesses can implement cost-saving measures and process improvements, leading to reduced operational expenses and increased profitability.

Better Inventory Management: Metrics such as inventory turnover, stockout rate, and order fill rate provide valuable information about inventory levels and availability. By tracking these metrics, businesses can optimize inventory management, minimize stockouts, reduce excess inventory, and ensure adequate product availability for customer orders.

Effective Decision-Making: Order management performance metrics serve as a valuable source of data for making informed decisions. By tracking and analyzing these metrics, businesses can identify trends, spot areas for improvement, and make data-driven decisions to optimize their order management processes, supply chain, and customer service strategies.

Improved Supplier Relationships: Metrics like on-time delivery and stockout rate can be used to evaluate the performance of suppliers. By tracking these metrics, businesses can identify suppliers who consistently meet delivery commitments and minimize stockouts, leading to more reliable supply chain partnerships and improved supplier relationships.

Continuous Process Improvement: Tracking order management performance metrics provides a benchmark for measuring performance and progress over time. By monitoring these metrics regularly, businesses can identify areas for improvement, set performance goals, and implement targeted process improvements to enhance overall order management efficiency and effectiveness.

Competitive Advantage: By consistently tracking and improving order management performance metrics, businesses can gain a competitive edge in the marketplace. Meeting or exceeding customer expectations in areas such as on-time delivery, order accuracy, and customer satisfaction can differentiate a business from its competitors and attract new customers.

Overall, tracking order management performance metrics enables businesses to identify areas of improvement, optimize operations, enhance customer satisfaction, and drive overall business success. It provides the data and insights needed to make informed decisions, implement process improvements, and stay ahead in a competitive market.

Frequently Asked Questions (FAQs) Associated with Order Management Performance Metrics

Following, we’ve discussed important frequently asked questions (FAQs) associated with order management performance metrics. Let’s learn:

Q: What are Key Performance Indicators (KPIs) for order management?

A: Key Performance Indicators (KPIs) for order management are metrics used to measure and evaluate the performance of order management processes. Some common KPIs include Order Cycle Time, Order Accuracy, Inventory Turnover, Stockout Rate, On-Time Delivery, Order Fill Rate, Order Return Rate, and Customer Complaints.

Q: Why are order management KPIs important?

A: Order management KPIs are important because they provide insights into the efficiency, accuracy, and effectiveness of order management processes. By tracking and analyzing these metrics, businesses can identify areas for improvement, optimize operations, enhance customer satisfaction, and drive overall business success.

Q: How do you calculate order management KPIs?

A: The calculation of order management KPIs depends on the specific metric being measured. Each KPI has its own formula and units of measurement. For example, Order Cycle Time is calculated as the duration from order placement to order fulfillment, while Order Accuracy is measured as the percentage of orders processed without errors. The formulas and calculations for each KPI can be found in their respective explanations.

Q: How frequently should order management KPIs be tracked?

A: The frequency of tracking order management KPIs depends on the business's specific needs and the dynamics of the industry. However, it is generally recommended to track KPIs regularly to monitor performance and identify trends. Tracking KPIs on a monthly or quarterly basis is common, but some businesses may choose to track them more frequently, such as weekly or even daily, to enable more proactive decision-making.

Q: How can I improve order management KPIs?

A: Improving order management KPIs involves implementing strategies and best practices specific to each metric. For example, to improve Order Cycle Time, streamlining order processing and optimizing inventory management can be beneficial. To enhance Order Accuracy, investing in training, implementing quality control checks, and utilizing technology solutions can help. Detailed strategies for improving each order management KPI are provided in their respective explanations.

Q: Are there any software or tools available to track order management KPIs?

A: Yes, there are various software solutions and tools available that can help businesses track and monitor order management KPIs. These tools often provide real-time visibility into order status, inventory levels, and performance metrics. They can help automate processes, streamline operations, and generate reports and analytics for better decision-making. Examples of such tools include order management systems (OMS), customer relationship management (CRM) software, and enterprise resource planning (ERP) systems.

Q: Can order management KPIs vary by industry?

A: Yes, order management KPIs can vary by industry. While certain KPIs such as Order Cycle Time, Order Accuracy, and On-Time Delivery are relevant across industries, some metrics may be more specific to certain sectors. For example, in retail or e-commerce, metrics like Order Fill Rate and Return Rate may carry greater significance, whereas in manufacturing, metrics related to inventory turnover and supply chain efficiency may be more relevant.

Q: How can order management KPIs help with decision-making?

A: Order management KPIs provide objective data and insights that can inform decision-making. By analyzing these metrics, businesses can identify areas for improvement, allocate resources effectively, set performance targets, and make informed decisions regarding process optimization, inventory management, supplier selection, customer service enhancements, and more.

Q: What steps can be taken to ensure accurate tracking and measurement of order management KPIs?

A: To ensure accurate tracking and measurement of order management KPIs, businesses should establish clear and standardized measurement methodologies. This includes defining the metrics, establishing data collection procedures, implementing reliable tracking systems, and ensuring data accuracy and consistency. Regular audits and reviews can help identify and address any issues or discrepancies in tracking and measurement.

Q: How can order management KPIs be used to assess supplier performance?

A: Order management KPIs can be utilized to assess supplier performance by measuring metrics such as On-Time Delivery, Stockout Rate, and Order Accuracy. By tracking these metrics specifically for supplier-related orders, businesses can evaluate the reliability, efficiency, and accuracy of their suppliers' order fulfillment processes. This assessment can help in supplier selection, contract negotiations, and ongoing supplier relationship management.

Q: Are there any industry benchmarks for order management KPIs?

A: Industry benchmarks for order management KPIs can vary, and it is advisable to consider benchmarks specific to your industry or sector. Industry associations, research reports, and professional networks can be valuable sources for obtaining benchmark data. However, it's important to note that benchmarks should be used as reference points and businesses should focus on continuous improvement based on their own historical performance and specific business objectives.

Q: How can order management KPIs be used for continuous improvement?

A: Order management KPIs serve as performance indicators and provide a basis for continuous improvement. By tracking these metrics over time, businesses can identify trends, patterns, and areas of underperformance. This allows for targeted process improvements, employee training, and adjustments to strategies and systems to enhance order management efficiency, accuracy, and customer satisfaction over time. Regular review and analysis of KPIs support a culture of continuous improvement within an organization.

Tracking and utilizing order management KPIs can bring valuable insights, inform decision-making, drive operational improvements, and ultimately contribute to the success of a business's order management processes.

Wrapping Up

In conclusion, tracking and analyzing order management performance metrics are essential for businesses to evaluate and optimize their order management processes. The various KPIs discussed in this article, such as Order Cycle Time, Order Accuracy, Inventory Turnover, Stockout Rate, On-Time Delivery, Order Fill Rate, Order Return Rate, and Customer Complaints, provide valuable insights into different aspects of order management.

By monitoring these metrics, businesses can identify areas for improvement, enhance operational efficiency, improve customer satisfaction, reduce costs, and gain a competitive advantage. Each metric provides specific benefits and requires targeted strategies for improvement, such as streamlining processes, implementing quality control measures, optimizing inventory management, enhancing communication, and leveraging technology solutions.

Efficient order management leads to improved operational performance, increased customer satisfaction, and better financial outcomes. It enables businesses to fulfill customer orders accurately and timely, maintain optimal inventory levels, minimize returns and stockouts, and address customer complaints promptly. By continuously tracking, analyzing, and improving order management metrics, businesses can drive continuous process enhancements and achieve their goals of delivering exceptional customer experiences and maximizing overall performance.

To achieve success in today's competitive landscape, businesses must prioritize order management performance, utilize data-driven insights, and adopt proactive strategies to improve key metrics. By doing so, they can enhance their order management capabilities, strengthen customer relationships, and position themselves for sustained growth and success.

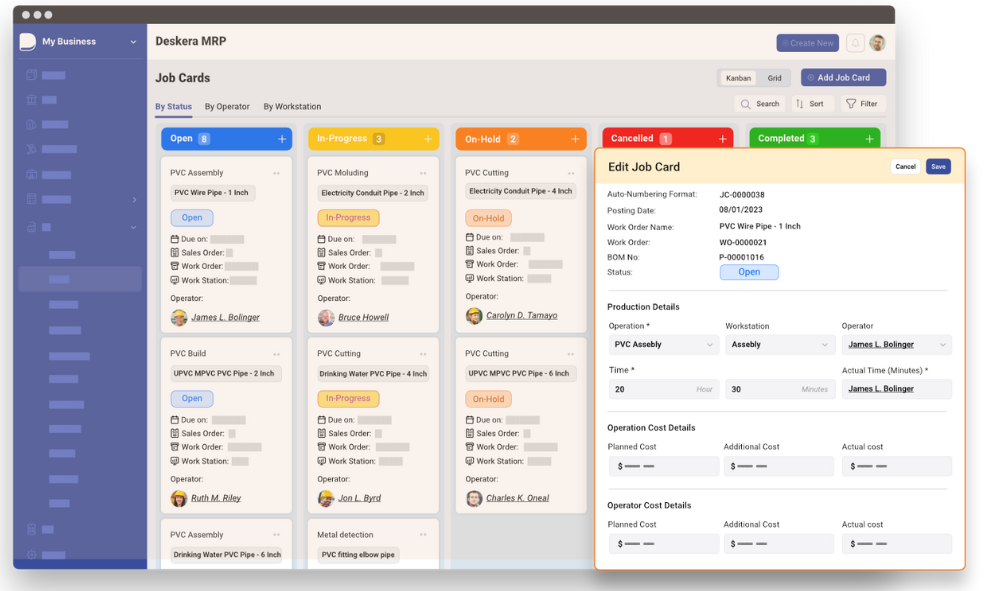

How Deskera Can Assist You?

Deskera ERP and MRP systems help you to keep your business units organized. The system's key features of demand forecasting with Deskera include as follows:

- Establish Demand Forecasting Process

- Automate Data Collection

- Monitor Market Trends

- Analyze Historical Data

- Estimate Future Demand

- Adjust Production Levels

- Manage Supply Chain...and much more!

- Deskera's integrated financial planning tools enable investors to better plan and track their investments. It can assist investors in making faster and more accurate decisions.

- Deskera CRM is a powerful solution that manages your sales and helps you close deals quickly. It not only enables you to perform critical tasks like lead generation via email, but it also gives you a comprehensive view of your sales funnel.

- Deskera Books allows you to better manage your accounts and finances. Maintain good accounting practices by automating tasks like billing, invoicing, and payment processing.

- Deskera People is a straightforward tool for centralizing your human resource management functions.

Final Takeaways

We've arrived at the last section of this guide. Let's have a look at some of the most important points to remember:

- Order management refers to the process of efficiently and effectively handling customer orders from the point of initiation to fulfillment and beyond. It involves the coordination and execution of various activities, such as order processing, inventory management, logistics, and customer service.

- Cost per Order (CPO) is a financial metric that measures the average cost incurred by a business to process and fulfill a single order. It provides insights into the efficiency and cost-effectiveness of the order management process.

- Internal Order Cycle Time refers to the duration it takes for an order to be processed and fulfilled within an organization. It encompasses all the internal processes involved, from the time an order is received until it is ready for shipment or delivery. Monitoring and optimizing the internal order cycle time is essential for improving operational efficiency, customer satisfaction, and overall business performance.

- Once an order is processed, the next step is to allocate inventory for the order. This involves checking the availability of products, updating inventory records, and reserving the necessary items. Efficient inventory allocation ensures that products are ready for fulfillment and minimizes the risk of stockouts or delays.

- The Order Fulfillment Cycle Time represents the overall time it took for the order to be processed, prepared, and delivered to the customer. A shorter Order Fulfillment Cycle Time generally indicates more efficient operations and faster delivery. However, it is important to note that the desired cycle time may vary based on industry standards, customer expectations, and the type of products being fulfilled.

- On-time Shipping Rate is a metric that measures the percentage of orders shipped and delivered to customers within the promised timeframe. It indicates the reliability and efficiency of the shipping process in meeting customer expectations.

- The Average Order Value indicates the typical amount of money customers spend per order. A higher Average Order Value suggests that customers tend to spend more with each transaction, which can lead to increased revenue and profitability. It helps businesses assess their pricing strategy, cross-selling or upselling effectiveness, and overall customer spending patterns.

Related Articles