Have you ever wondered how leading retailers, manufacturers, and procurement teams optimize their purchasing strategies to maximize efficiency and cost savings? The answer lies in Category Management—a strategic approach that organizes similar products or services into groups to enhance procurement, supplier management, and overall business performance. By segmenting purchases into well-defined categories, businesses can negotiate better contracts, streamline inventory, and improve customer satisfaction.

Category management is more than just organizing products—it’s about data-driven decision-making, supplier collaboration, and strategic sourcing. When implemented effectively, it helps businesses reduce costs, mitigate risks, and enhance operational efficiency. Whether in retail, manufacturing, or supply chain management, category management ensures that purchasing decisions align with broader business goals. From optimizing supplier relationships to analyzing market trends, this approach plays a crucial role in improving business profitability.

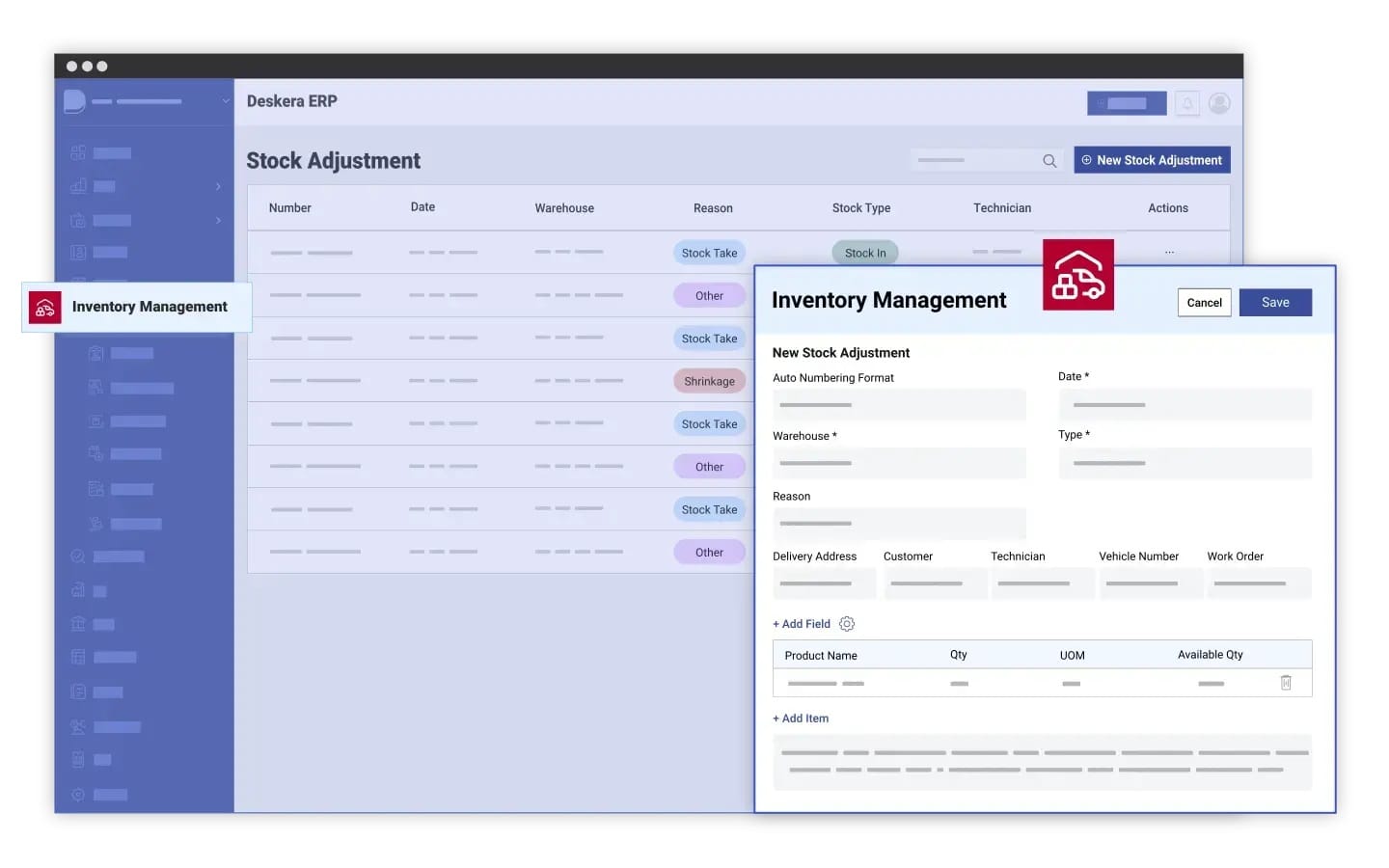

To manage procurement and inventory effectively, businesses need robust tools that automate workflows and provide real-time insights. Deskera ERP offers an all-in-one solution for inventory control, procurement, and supplier management, helping companies implement category management strategies seamlessly. With features like demand forecasting, automated purchasing, and AI-driven insights, Deskera ERP empowers businesses to make informed, data-backed decisions for efficient category management.

In this blog, we will explore everything you need to know about category management, from its key components and benefits to best practices and future trends. Whether you’re new to the concept or looking to refine your existing strategy, this guide will help you unlock the full potential of category management for your business.

What is Category Management?

Category management is a strategic approach to procurement and supply chain management that involves grouping similar products, services, or commodities into categories to optimize purchasing decisions and maximize value. Instead of managing purchases in isolation, businesses classify them based on characteristics such as type, value, supplier, risk, or department. This systematic approach allows organizations to gain better visibility into their spending patterns, improve supplier management, and enhance overall efficiency.

By organizing procurement into distinct categories, businesses can streamline processes, negotiate better contracts, and reduce the total cost of ownership (TCO) for each category. Research shows that firms that fully optimize category management can achieve up to $114 million in savings and a 500% return on investment, in addition to reducing supply chain risks. This approach fosters strategic sourcing, enables economies of scale, and ensures long-term supplier collaboration, ultimately leading to cost savings and improved procurement outcomes.

Unlike traditional sourcing, which focuses on one-time cost reductions, category management is an ongoing, data-driven process that aligns business objectives with supplier capabilities. It involves analyzing market trends, supplier performance, and category dynamics to develop sourcing strategies that deliver long-term value. Senior leaders play a key role in defining category strategies, ensuring that procurement decisions align with broader organizational goals.

With category management, organizations move from a reactive to a proactive procurement strategy, improving operational agility and reducing risks. By leveraging advanced procurement solutions like Deskera ERP, businesses can automate category management workflows, monitor category-specific metrics, and enhance supplier relationships through AI-driven insights. This structured approach to procurement empowers organizations to maximize efficiency, drive innovation, and achieve sustainable growth in today’s competitive market.

Category Management vs. Strategic Sourcing

While both category management and strategic sourcing focus on optimizing procurement and supplier relationships, they differ in their scope, objectives, and approach. Understanding these distinctions helps organizations align their procurement strategies with business goals more effectively.

1. Scope: Holistic vs. Transactional Approach

- Category Management takes a holistic and long-term view by organizing goods and services into categories based on similar characteristics. It focuses on end-to-end category performance, including supplier management, cost control, risk mitigation, and value maximization.

- Strategic Sourcing, on the other hand, is more transactional and event-driven. It aims to identify, evaluate, and negotiate with suppliers to secure the best terms for a specific sourcing need at a given time.

2. Objective: Value Optimization vs. Cost Savings

- The primary goal of category management is to optimize the total cost of ownership (TCO) while ensuring quality, supplier collaboration, and long-term value creation. It aligns procurement strategies with overall business goals.

- Strategic sourcing primarily focuses on cost savings, efficiency, and supplier selection. It aims to find the best supplier at the best price while meeting immediate procurement needs.

3. Approach: Continuous Management vs. One-Time Sourcing

- Category Management is an ongoing process that involves data analysis, market trends evaluation, supplier relationship management (SRM), and continuous performance tracking. It requires active engagement with suppliers and internal stakeholders to refine procurement strategies.

- Strategic Sourcing is typically a one-time or periodic activity, focusing on supplier selection and contract negotiation for a particular procurement need. Once the contract is secured, the process may not involve continuous supplier management.

4. Role of Senior Leadership

- In category management, senior executives play a crucial role in setting category strategies, defining objectives, and ensuring alignment with business priorities.

- Strategic sourcing is more operational and often led by procurement teams without the direct involvement of senior leadership beyond contract approvals.

Which Approach Is Better?

Both approaches are valuable, but category management provides a more comprehensive and strategic framework for procurement. While strategic sourcing helps secure favorable supplier contracts, category management ensures long-term value, cost efficiency, and risk management across the entire supply chain.

Organizations using Deskera ERP can streamline both category management and strategic sourcing, leveraging automation, real-time analytics, and supplier performance tracking to enhance procurement efficiency and drive cost savings.

Key Components of Category Management

Effective category management consists of several interconnected components that help businesses optimize procurement, streamline supplier relationships, and drive profitability. These components ensure that purchasing decisions are strategic, data-driven, and aligned with organizational goals.

1. Category Definition

Category management begins with clearly defining product or service categories based on shared characteristics, such as function, supplier type, or market demand. Proper segmentation helps organizations structure their procurement strategy, align inventory management with business needs, and ensure that each category contributes effectively to overall company objectives.

2. Strategic Sourcing

Strategic sourcing focuses on identifying, evaluating, and selecting the best suppliers to optimize cost, quality, and delivery performance. In category management, this involves negotiating long-term contracts, leveraging economies of scale, and ensuring suppliers align with the company's strategic goals. A well-executed strategic sourcing process enhances cost efficiency and strengthens supply chain resilience.

3. Supplier Relationship Management (SRM)

Strong supplier relationships are essential for mutual growth, innovation, and risk mitigation. SRM involves transparent communication, collaborative planning, and continuous performance evaluation. By fostering long-term supplier partnerships, businesses can improve service levels, reduce procurement risks, and create a more agile supply chain.

4. Data Analysis and Insights

Data analytics plays a crucial role in category management by providing insights into market trends, consumer behavior, and purchasing patterns. By leveraging advanced analytics tools, businesses can make informed decisions about product assortments, pricing strategies, and supplier selection. Data-driven insights also help in identifying cost-saving opportunities and improving procurement efficiency.

5. Performance Measurement and Optimization

Measuring category performance ensures continuous improvement and alignment with business objectives. Organizations use key performance indicators (KPIs) such as sales, profitability, customer satisfaction, and supplier performance to evaluate category effectiveness. Regular performance analysis helps identify inefficiencies, adjust strategies, and enhance overall procurement success.

By integrating these components, businesses can transform their procurement process from a reactive cost-cutting function into a proactive strategy for growth and efficiency. Leveraging Deskera ERP, organizations can automate category management workflows, track performance metrics in real-time, and gain AI-driven insights for better decision-making.

The 4 P’s of Category Management: A Holistic Approach

Successful category management is built on four key pillars—Planning, Procurement, Performance, and Promotion. These elements work together to streamline procurement, optimize supplier relationships, and enhance category performance. Let’s explore each in detail.

1. Planning: Defining Strategy and Objectives

The foundation of category management begins with strategic planning, where businesses define their goals, objectives, and category-specific strategies. This phase involves analyzing the category’s role within the organization, setting performance benchmarks, and developing actionable plans to optimize procurement, supplier engagement, and cost efficiency. Clear planning ensures alignment with overall business objectives and long-term sustainability.

2. Procurement: Sourcing and Supplier Contracting

Once the strategy is in place, the next step is procurement, which focuses on sourcing suppliers, negotiating contracts, and ensuring quality standards. This phase involves selecting the right suppliers, leveraging economies of scale, and fostering strong partnerships to drive cost savings and operational efficiency. A well-structured procurement process ensures organizations secure competitive pricing, high-quality products, and reliable supply chains.

3. Performance: Monitoring and Optimization

Category management doesn’t stop at procurement—continuous performance monitoring is essential. Organizations track key performance indicators (KPIs) such as supplier reliability, cost savings, product quality, and delivery timelines.

By analyzing data and supplier performance metrics, businesses can identify inefficiencies, optimize sourcing strategies, and enhance overall category performance. This phase ensures that category management efforts remain effective and aligned with business goals.

4. Promotion: Driving Awareness and Engagement

Beyond procurement and performance, successful category management involves promoting category initiatives within the organization and the market. This includes marketing strategies, stakeholder engagement, and internal communication to drive category adoption and maximize value. By aligning category initiatives with business growth strategies, companies can create a more competitive and resilient procurement function.

By integrating these 4 P’s, organizations can enhance cost efficiency, strengthen supplier relationships, and improve procurement performance. Leveraging tools like Deskera ERP, businesses can automate procurement workflows, track supplier performance, and gain real-time insights to make data-driven decisions.

The 8-Step Process of Category Management

Category management is a strategic approach that businesses use to manage product categories effectively. It helps optimize sales, profitability, and efficiency by treating each category as a separate business unit.

Here’s a structured 8-step process for implementing category management:

1. Define the Category

- The first step is to clearly define the category by grouping similar products or services.

- This definition impacts inventory planning, pricing, promotions, and overall strategy.

- Example: A supermarket may categorize products into "organic foods," "dairy products," or "frozen meals" to align with customer preferences.

2. Role Assessment

- Determine the role of each category in the business strategy.

- Categories can serve different roles, such as traffic drivers, revenue generators, or seasonal demand boosters.

- Example: A retail store might position "holiday decorations" as a seasonal traffic driver while treating "luxury skincare" as a high-margin category.

3. Performance Analysis

- Analyze the current performance of the category using key performance indicators (KPIs) such as sales, margins, and customer demand.

- Identify strengths, weaknesses, and opportunities for improvement.

- Example: An electronics retailer might compare the sales of gaming laptops vs. business laptops to refine marketing strategies.

4. Set Objectives and Targets

- Establish clear, measurable goals that align with the company’s overall business strategy.

- Goals could include increasing market share, improving profitability, or enhancing customer experience.

- Example: A beverage brand might aim to increase its energy drink category sales by 20% within a year through targeted promotions.

5. Strategy Development

- Develop tailored strategies to achieve the set objectives.

- Consider market trends, competition, and customer preferences.

- Example: A bookstore chain may enhance its "self-help" category by featuring bestsellers at checkout counters and hosting book signings.

6. Tactical Execution (4Ps of Category Management)

- Product (Assortment): Select the right mix of products.

- Price: Set competitive and value-driven pricing.

- Placement: Optimize shelf or online positioning.

- Promotions: Implement targeted marketing campaigns.

- Example: A grocery store may place gluten-free snacks in a health-conscious aisle to attract customers with dietary preferences.

7. Implementation

- Execute the planned strategies across all business units.

- Ensure store teams, suppliers, and marketing teams are aligned.

- Example: A supermarket launching a new organic category may train employees on product benefits and adjust store layouts for better visibility.

8. Review and Optimize

- Continuously monitor category performance and refine strategies based on data insights.

- Adjust pricing, product offerings, and marketing tactics as needed.

- Example: A fashion retailer may discontinue underperforming product lines and introduce trending designs based on seasonal sales data.

Category management is a dynamic process that requires strategic planning, execution, and continuous optimization. By following this 8-step process, businesses can enhance efficiency, meet consumer demands, and drive long-term profitability.

Benefits of Category Management

Category management offers a strategic framework for procurement and retail teams, driving efficiency, cost savings, and competitive advantage. Here are the key benefits:

1. Improved Insights and Spend Visibility

- Categorized spend provides businesses with a clearer understanding of costs, vendor performance, and market trends.

- Companies can track expenditures, identify savings opportunities, and optimize procurement decisions.

2. Increased Cost Savings

- Through supplier consolidation and volume-based negotiations, category management reduces procurement costs.

- Managers leverage economies of scale to secure better prices and long-term savings.

3. Reduced Risk Exposure

- By building long-term supplier relationships and understanding vendor reliability, businesses mitigate supply chain risks.

- Risk assessments and contingency planning help address market volatility and geopolitical uncertainties.

4. Greater Procurement Efficiency

- Digitalization and automation in category management reduce redundancies, streamline operations, and enhance response times.

- Teams can focus on value-added activities instead of repetitive administrative tasks.

5. Enhanced Supplier Relationships

- Category-based procurement fosters deeper, strategic partnerships with suppliers.

- Stronger relationships lead to better contract terms, innovative solutions, and improved supplier responsiveness.

6. Improved Margins and Sales Growth

- Understanding customer demand within each category allows businesses to optimize pricing, promotions, and product assortments.

- Negotiating better supplier terms and reducing markdowns on slow-moving inventory improves profit margins.

7. Better Compliance and Governance

- Category management ensures suppliers meet ethical, environmental, and legal standards.

- Clear policies and monitoring systems enhance adherence to regulatory and corporate responsibility requirements.

8. Increased Innovation and Market Insights

- Close collaboration with suppliers encourages new product ideas and efficiency improvements.

- Regular market analysis helps businesses stay ahead of industry trends and competitive shifts.

9. Alignment with Business Objectives

- Category management integrates procurement strategies with overall business goals.

- It helps drive revenue growth, enhance product differentiation, and improve customer satisfaction.

10. Scalability for Business Growth

- A structured approach enables businesses to expand efficiently by managing increased demand and supplier networks.

- Procurement teams can adapt seamlessly to new markets, product lines, and operational needs.

By implementing category management, businesses can enhance procurement strategies, strengthen supplier networks, and drive long-term success.

Challenges in Implementing Category Management

While category management offers significant benefits, its implementation can be complex and requires overcoming various challenges. Here are some of the key obstacles businesses face:

1. Resistance to Change

- Employees accustomed to traditional procurement methods may resist shifting to category management.

- Stakeholder buy-in across departments is essential to ensure smooth adoption.

- Change management strategies, effective communication, and training programs are necessary to drive acceptance.

2. Data Complexity and Integration Issues

- Category management depends on accurate spend analysis and supplier performance metrics.

- Managing large volumes of data from disparate sources can be challenging.

- Organizations need advanced analytics tools and skilled analysts to clean, interpret, and leverage data effectively.

3. Supplier Dependence and Risk Exposure

- Relying too heavily on a few key suppliers increases vulnerability to supply chain disruptions.

- Economic shifts, geopolitical issues, and operational failures can impact primary suppliers.

- Businesses must diversify their supplier base and implement contingency plans to mitigate risks.

4. Limited Market Visibility

- Some categories, especially in specialized or rapidly evolving industries, lack clear supplier market insights.

- Without proper visibility, businesses may struggle to secure competitive pricing or identify emerging suppliers.

- Continuous market research and supplier intelligence are needed to enhance strategic sourcing.

5. Balancing Standardization With Flexibility

- Standardized procurement processes drive efficiency but may limit adaptability to category-specific needs.

- Over-standardization can hinder innovation, while excessive flexibility may result in inconsistent practices.

- A balanced approach is needed to maintain procurement efficiency while allowing category-specific strategies.

6. Resource and Skill Constraints

- Managing categories effectively requires expertise in strategic sourcing, negotiation, and supplier management.

- Many procurement teams face budget constraints or lack specialized talent.

- Investing in training, expanding the team, or leveraging external expertise can help address these limitations.

7. Sustainability and Compliance Challenges

- Businesses are under growing pressure to align procurement with ESG (Environmental, Social, and Governance) standards.

- Ensuring suppliers meet sustainability and compliance requirements requires ongoing assessment and collaboration.

- Category managers must work closely with suppliers to track compliance, encourage sustainable practices, and meet corporate responsibility goals.

Overcoming these challenges requires a strategic approach, investment in technology and talent, and a commitment to continuous improvement. By addressing these obstacles, organizations can unlock the full potential of category management and drive long-term procurement success.

Best Practices for Successful Category Management

Category management is a strategic approach to procurement that focuses on optimizing spend across different product and service categories. Implementing an effective category management strategy requires careful planning and execution.

Here are some best practices to ensure success:

1. Establish a Dedicated Category Management Team

- Assign a category manager and a cross-functional team with stakeholders from procurement, finance, marketing, and sales.

- Ensure the team is responsible for overseeing market trends, supplier relationships, and category-specific strategies.

- Provide ongoing training and development to enhance category expertise.

2. Define and Standardize Category Taxonomy

- Create a consistent classification system across the organization to enhance visibility into spend.

- Align with universal standards like UNSPSC (United Nations Standard Products and Services Code) or develop internal categories tailored to business needs.

- Standardization helps in data accuracy, reporting, and strategic decision-making.

3. Leverage Automated Solutions for Data Centralization

- Utilize procurement software and analytics tools to consolidate spend data in a single platform.

- Ensure that real-time tracking and reporting capabilities are in place to improve decision-making.

- Use AI-driven insights to spot trends, automate tasks, and enhance supplier management.

4. Develop Category-Specific Strategies

- Define clear objectives and key performance indicators (KPIs) for each category.

- Implement strategies such as segmentation, SKU rationalization, and price optimization to maximize efficiency.

- Align category plans with the organization’s broader business goals and market conditions.

5. Engage Stakeholders and Ensure Cross-Departmental Collaboration

- Foster strong communication between procurement, finance, sales, and other departments.

- Use analytics tools and reports to demonstrate category management success and gain stakeholder buy-in.

- Encourage feedback loops to refine strategies continuously.

6. Build Strong Supplier Relationships

- Shift focus from cost-cutting alone to value-driven supplier collaborations.

- Establish long-term partnerships that foster innovation and supply chain resilience.

- Implement supplier performance management systems with regular evaluations and feedback mechanisms.

7. Incorporate Third-Party Data for Market Intelligence

- Use external data sources to complement internal insights and improve strategic sourcing decisions.

- Stay informed about supplier risks, pricing trends, and market fluctuations.

- Benchmark category performance against industry best practices.

8. Continuously Optimize the Category Lifecycle Process

- Regularly review category performance and refine strategies based on new data.

- Conduct periodic assessments to identify areas for improvement.

- Implement a structured feedback mechanism for internal and external stakeholders.

9. Utilize Technology to Enhance Efficiency

- Invest in procurement and category management software to streamline operations.

- Leverage AI and automation to analyze data, categorize spend, and make proactive recommendations.

- Implement digital dashboards for real-time visibility into category performance.

10. Monitor and Adjust Strategies as Needed

- Track KPIs such as cost savings, supplier performance, and procurement efficiency.

- Be flexible in adapting to market changes and organizational shifts.

- Conduct periodic audits to ensure compliance and continuous improvement.

By implementing these best practices, organizations can create a structured, data-driven approach to category management, leading to optimized procurement processes, cost savings, and improved supplier collaboration.

Key Features to Look for in Category Management Software

The right category management software can significantly enhance procurement functions by enabling more strategic decision-making and streamlining daily operations. Businesses must carefully evaluate software features to ensure they align with long-term goals and industry-specific needs.

Below are the essential features to look for when selecting category management software.

1. Comprehensive Data Analytics: Data-Driven Decision Making

In category management, data analytics is the foundation for strategic procurement. The software should provide robust tools that track spending patterns, analyze market trends, and evaluate supplier performance across various categories.

Key Features to Look For:

- Spend Analysis Dashboards: Helps track procurement expenditures, identify cost-saving opportunities, and optimize category budgets.

- Predictive Analytics: Leverages historical data and AI-driven insights to forecast demand, supplier performance, and potential market fluctuations.

- KPI Tracking: Monitors critical procurement metrics such as cost reduction, supplier efficiency, and contract compliance to ensure data-driven decision-making.

With comprehensive data analytics, procurement teams can move from reactive to proactive category management, making more informed and strategic choices.

2. Supplier Management: Strengthening Vendor Relationships

Building and managing strong supplier relationships is at the core of successful category management. Effective software should offer tools that monitor supplier performance, manage contracts, and facilitate communication.

Key Features to Look For:

- Supplier Scorecards: Tracks key performance indicators (KPIs) such as delivery timeliness, quality assurance, and compliance.

- Automated Supplier Onboarding: Streamlines the supplier approval process, reducing manual effort and improving operational efficiency.

- Contract Management Tools: Ensures smooth contract negotiation, renewal reminders, and compliance tracking.

A strong supplier management module ensures that procurement teams can maintain high-quality supplier relationships while mitigating risks associated with unreliable vendors.

3. Risk Assessment Capabilities: Proactive Supply Chain Risk Management

Risk assessment is a crucial element in category management, helping businesses anticipate and mitigate potential disruptions. The right software should offer comprehensive risk assessment tools that monitor supplier risk levels, assess market fluctuations, and flag potential supply chain disruptions.

Key Features to Look For:

- Automated Risk Alerts: Notifies users about supplier financial instability, geopolitical risks, or regulatory changes affecting procurement.

- Market Intelligence Tools: Provides insights into industry trends, supplier performance history, and potential risks before making sourcing decisions.

- Compliance Tracking: Monitors adherence to safety, ethical, and regulatory standards, ensuring suppliers meet legal and quality requirements.

With real-time risk assessment, businesses can take proactive measures to safeguard procurement operations against unexpected disruptions.

4. User-Friendly Interface: Ensuring Organization-Wide Adoption

A complex and difficult-to-navigate software interface can hinder adoption across an organization. Since category management software is used by cross-functional teams with varying technical expertise, a user-friendly design is critical.

Key Features to Look For:

- Intuitive Dashboard: Provides a centralized view of all category data, supplier performance, and procurement activities.

- Customizable Reports: Allows teams to generate reports tailored to their specific needs, making it easier to track progress and make informed decisions.

- Role-Based Access Controls: Ensures different team members can access only the relevant data, improving security and operational efficiency.

A well-designed, intuitive interface increases adoption rates, making it easier for procurement teams to leverage the software’s full potential.

5. Seamless System Integration: Breaking Down Data Silos

Category management software should not function in isolation. It should seamlessly integrate with other business systems, such as Enterprise Resource Planning (ERP) platforms, supplier networks, and financial software.

Key Features to Look For:

- ERP Integration: Ensures real-time data synchronization between procurement and financial departments for better budgeting and spend control.

- Supplier Network Integration: Enables easy access to supplier catalogs, reducing procurement lead time and improving supplier collaboration.

- API Connectivity: Supports custom integrations with third-party applications, allowing businesses to tailor workflows to their unique requirements.

By integrating with existing systems, category management software becomes a central hub for all procurement-related data, enhancing transparency and efficiency.

6. Sustainability & Compliance Tracking: Aligning Procurement with ESG Goals

As businesses prioritize sustainability and regulatory compliance, category management software should include features that track Environmental, Social, and Governance (ESG) metrics.

Key Features to Look For:

- Supplier Compliance Audits: Monitors supplier adherence to ethical labor practices, environmental standards, and industry regulations.

- ESG Performance Dashboards: Provides real-time insights into sustainability initiatives and supplier sustainability performance.

- Automated Compliance Reporting: Simplifies documentation and reporting for regulatory bodies and internal audits.

With built-in sustainability tracking, businesses can ensure procurement aligns with corporate social responsibility (CSR) initiatives and industry compliance standards.

7. Automation & AI-Driven Insights: Enhancing Efficiency and Future-Readiness

Automation and artificial intelligence (AI) have become game-changers in category management, helping businesses streamline operations and gain advanced insights.

Key Features to Look For:

- Automated Workflows: Reduces manual effort in supplier onboarding, contract renewals, and invoice processing.

- AI-Powered Market Intelligence: Identifies cost-saving opportunities, optimal sourcing strategies, and category trends based on historical and real-time data.

- Smart Recommendations: Provides step-by-step guidance on category strategy, sourcing decisions, and supplier negotiations.

By leveraging AI-driven insights and automation, businesses can enhance efficiency, minimize errors, and stay ahead of market changes.

Selecting category management software with these key features ensures a streamlined procurement process, improved supplier relationships, and enhanced decision-making. By focusing on data analytics, risk management, automation, and seamless integration, businesses can future-proof their procurement strategies and drive long-term efficiency.

By prioritizing these essential features, organizations can transform their category management approach—turning procurement into a strategic function that drives value across the supply chain.

7 Steps for Developing a Robust Category Management Plan

A well-defined category management plan is essential for optimizing procurement, improving supplier relationships, and reducing costs. The following seven steps outline a strategic approach, illustrated with an example of a hypothetical electronics manufacturer, TechNova Solutions.

1. Requirements Assessment: Identifying Procurement Gaps

The first step involves evaluating existing procurement practices to identify inefficiencies and improvement areas. Engaging with stakeholders helps set realistic goals and timelines.

Example: TechNova Solutions conducts an internal audit and identifies high procurement costs in its consumer electronics division, particularly for semiconductor chips used in smartphones and laptops.

2. Spend Analysis: Establishing a Performance Baseline

Analyzing current expenditures and categorizing spend data helps uncover cost-saving opportunities. This step includes classifying procurement costs and assessing supplier pricing trends.

Example: After analyzing procurement data, TechNova discovers that chipsets and display panels account for a significant portion of production costs. The company decides to consolidate suppliers to secure bulk discounts and improve negotiating power.

3. Category Segmentation and Prioritization

Segmenting procurement costs into specific categories—such as strategic importance, risk levels, and cost impact—allows businesses to prioritize areas with the highest value potential.

Example: TechNova prioritizes advanced semiconductor procurement, as supply chain disruptions in this category could significantly impact production. The company also focuses on sourcing sustainable packaging materials to align with its environmental goals.

4. Strategy Formulation: Developing Category-Specific Approaches

Once categories are segmented, businesses must develop tailored procurement strategies, considering demand forecasts, supplier relationships, and market risks.

Example: TechNova collaborates with key semiconductor manufacturers to establish long-term contracts, ensuring consistent supply and stable pricing. Additionally, the company explores alternative suppliers in different regions to mitigate geopolitical risks affecting semiconductor availability.

5. Implementation and Execution: Putting the Plan into Action

This step involves executing the category strategies by assigning responsibilities, setting performance benchmarks, and allocating resources efficiently.

Example: TechNova rolls out an automated supplier management platform, enabling seamless communication and order tracking. The company also introduces performance-based incentives for suppliers to enhance quality and delivery efficiency.

6. Performance Monitoring: Tracking and Adjusting Strategies

By continuously monitoring key performance indicators (KPIs), businesses can assess the effectiveness of their category management plan and make necessary adjustments.

Example: With its new supplier performance dashboard, TechNova tracks cost savings, supplier reliability, and defect rates. If a supplier fails to meet quality benchmarks, the company has contingency plans to shift orders to secondary suppliers.

7. Continuous Improvement: Adapting to Market Changes

A successful category management plan requires ongoing optimization through innovation, market research, and adoption of emerging best practices.

Example: TechNova establishes a category management task force that regularly reviews market trends and explores AI-driven procurement tools for smarter sourcing decisions. The company also expands its successful semiconductor strategy to other high-cost components, such as battery cells for electric devices.

Following these seven steps ensures a structured and dynamic category management plan that enhances procurement efficiency, strengthens supplier relationships, and delivers long-term cost savings. Businesses that continuously refine their strategies will maintain a competitive edge in an evolving market landscape.

Future Trends in Category Management

As businesses navigate evolving market conditions, category management is transforming to enhance efficiency, cost savings, and supplier collaboration.

Here are the key future trends shaping category management:

1. AI and Data-Driven Procurement

Artificial intelligence (AI) and big data analytics are revolutionizing category management by enabling predictive insights, automation, and intelligent decision-making.

For example, AI-powered spend analysis tools can detect cost-saving opportunities, predict supplier risks, and optimize procurement strategies in real time.

2. Sustainable and Ethical Sourcing

Companies are prioritizing sustainability and ethical procurement to meet regulatory requirements and consumer expectations.

Many businesses are adopting eco-friendly materials, carbon footprint tracking, and fair trade sourcing in their category management strategies to align with sustainability goals.

3. Supplier Collaboration and Risk Management

Stronger supplier relationships and risk mitigation strategies are essential for supply chain resilience.

To improve supplier collaboration, businesses are investing in real-time supplier monitoring tools to assess vendor performance and proactively address potential disruptions.

4. Cloud-Based and Blockchain-Enabled Procurement

Cloud platforms and blockchain technology are enhancing transparency, security, and efficiency in procurement.

Blockchain-powered smart contracts, for instance, enable secure and automated transactions between buyers and suppliers, reducing administrative overhead and improving trust.

5. AI-Powered Demand Forecasting

Advanced AI models are improving demand forecasting, helping companies align procurement strategies with market needs.

AI-driven predictive analytics assist businesses in optimizing inventory levels, reducing excess stock, and preventing shortages that could impact operations.

6. Agile and Flexible Procurement Strategies

Businesses are shifting to agile procurement models to quickly adapt to market changes and supply chain disruptions.

Many companies are leveraging multi-supplier sourcing strategies to reduce dependence on a single vendor, ensuring continuity in procurement operations even during supply chain fluctuations.

7. Digital Supplier Marketplaces

Online supplier marketplaces are growing, offering businesses access to a diverse range of vendors and competitive pricing.

Platforms such as Deskera ERP provide real-time supplier comparisons, automated procurement, and contract management tools, allowing organizations to make more informed sourcing decisions.

The future of category management is driven by digital transformation, sustainability, AI integration, and supply chain resilience. Businesses that embrace these trends will gain a competitive edge, ensuring cost efficiency and long-term procurement success.

How Deskera ERP Can Help with Category Management

Effective category management requires robust tools to streamline procurement, optimize inventory, and enhance supplier collaboration. Deskera ERP provides an all-in-one solution to manage procurement categories efficiently, ensuring cost savings, transparency, and agility.

1. AI-Driven Spend Analysis for Smarter Decisions

Deskera ERP offers automated spend tracking and analytics, allowing businesses to identify cost-saving opportunities within different procurement categories.

- AI-powered insights help in analyzing purchasing patterns.

- Identifies high-spend categories and suggests supplier consolidation strategies.

Example: A manufacturing company using Deskera ERP can track raw material expenses across categories like metals, plastics, and electronics, ensuring better budget allocation.

2. Advanced Inventory Categorization and Control

With automated inventory tracking, Deskera ERP enables businesses to categorize stock based on demand, value, and usage patterns.

- Supports ABC analysis to prioritize high-value inventory.

- Prevents overstocking and understocking with real-time demand forecasting.

Example: A retail business can categorize products into high-demand, seasonal, and slow-moving items for optimized stocking.

3. Seamless Supplier Management and Collaboration

Deskera ERP improves supplier relationship management by centralizing vendor data, contract terms, and performance metrics.

- Provides a supplier portal for real-time communication and order tracking.

- Automates purchase orders, reducing manual procurement errors.

Example: A business managing multiple suppliers for office supplies can compare vendor pricing, quality, and lead times in a single dashboard.

4. Customizable Procurement Workflows

The system allows businesses to create custom procurement workflows, ensuring compliance and efficiency in category management.

- Enables multi-level approval processes for purchasing.

- Reduces procurement cycle times with automated workflows.

Example: A manufacturing company can set up an automated approval process for bulk purchases exceeding a predefined budget.

5. Real-Time Reporting and Performance Monitoring

Deskera ERP provides real-time dashboards and analytics to track category performance, supplier efficiency, and procurement costs.

- Generates reports on category-wise spending, cost savings, and risk assessment.

- Helps businesses adjust procurement strategies based on data-driven insights.

Example: A distributor can monitor the performance of different product categories and optimize sourcing based on sales trends.

6. Integration with Financial and Supply Chain Modules

Deskera ERP seamlessly integrates procurement with accounting, inventory, and supply chain management, offering end-to-end visibility.

- Ensures accurate cost allocation across different procurement categories.

- Helps align purchasing decisions with financial goals.

Example: A logistics company using Deskera ERP can sync procurement data with financial reports for better expense tracking.

Key Takeaways

- Category management is a strategic approach to procurement and inventory management that optimizes spending, supplier relationships, and operational efficiency.

- Implementing category management helps businesses achieve cost savings, improve supply chain resilience, and enhance overall procurement efficiency.

- A robust category management plan includes requirements assessment, spend analysis, category segmentation, strategy formulation, implementation, performance monitoring, and continuous improvement.

- Successful category management involves cross-functional collaboration, leveraging data analytics, supplier consolidation, and technology adoption for better decision-making.

- Common challenges include lack of data visibility, supplier risks, resistance to change, and misalignment with business goals, which require proactive strategies to overcome.

- Emerging trends such as AI-driven analytics, automation, sustainability-focused procurement, and digital supply chain integration are shaping the future of category management.

- Deskera ERP streamlines category management with automated spend tracking, real-time inventory categorization, supplier management, custom procurement workflows, and performance analytics, driving efficiency and cost savings.

Related Articles