Food manufacturing is a highly regulated industry, and quality control helps ensure that products meet the stringent standards set by regulatory bodies. By following quality control guidelines, food manufacturers can minimize the risk of contamination and provide safe and high-quality food to their customers.

Quality control also helps ensure that products are consistent across batches and aren’t affected by changes in production methods. In this article, we will learn about a few ways in which we can improve the quality of food manufacturing processes.

This article covers the following:

- Key Components of Food Manufacturing Quality Control

- Understanding Food Safety Regulations

- Developing Comprehensive Quality Control Programs

- Implementing Effective Traceability Procedures

- Best Practices for Food Manufacturing Quality Control

- How can Deskera assist you?

Key Components of Food Manufacturing Quality Control

Food manufacturing is a complex and highly regulated industry, with a variety of quality control measures in place to ensure the safety and integrity of the product. Quality control is an essential part of food manufacturing, as it ensures that the finished product meets the highest standards of safety and quality.

As such, it is important for food manufacturers to understand the key components of quality control and how to implement them effectively in their operations. The first component of food manufacturing quality control is ingredient selection and control.

It is essential for food manufacturers to select the highest quality ingredients for their products, as this will ensure the safety and consistency of the final product. This involves carefully evaluating suppliers, testing ingredients for quality and safety, and establishing protocols to ensure that only approved ingredients are used.

The second component of food manufacturing quality control is process control. This includes documenting and monitoring all steps of the food manufacturing process, from raw material selection and storage to the finished product.

Establishing and following standard operating procedures (SOPs) is essential for ensuring that the process is consistent and safe. Process control also involves using automated systems to track product quality and traceability.

The third component of food manufacturing quality control is testing and inspection. Testing and inspection are essential for ensuring that the finished product meets the required safety and quality standards.

This involves performing physical, chemical, or microbiological tests on the product, as well as visual inspections. Testing is also essential for monitoring the process, as it can detect any problems or contamination that may occur during the manufacturing process.

Finally, food manufacturing quality control also involves documenting and reporting. This involves collecting and recording data throughout the manufacturing process, including product testing results, process controls, and inspections.

This data must be documented and reported in order to ensure compliance with industry standards and regulations. In summary, the key components of food manufacturing quality control are ingredient selection and control, process control, testing and inspection, and documentation and reporting. By implementing these components, food manufacturers can ensure that their products are safe, consistent, and of the highest quality.

Understanding Food Safety Regulations

Understanding Food Safety Regulations is essential for any food manufacturing business. Food safety regulations are put in place to protect consumers from contamination, spoilage, and other health hazards.

The first step in understanding food safety regulations is to familiarize yourself with the different types of regulations. The most common type of food safety regulation is the Hazard Analysis and Critical Control Points (HACCP) system.

This system is designed to identify and control potential hazards in the production process. It focuses on preventing contamination, eliminating potential hazards, and monitoring procedures to ensure that they are being followed properly.

The second type of food safety regulation is the Good Manufacturing Practices (GMPs). GMPs are designed to ensure that food is produced in a clean and safe manner. They include requirements for the proper handling, storage, and labeling of food products.

The third type of food safety regulation is the Food and Drug Administration (FDA) Food Code. This code outlines the requirements for food safety, labeling, and other aspects of food production.

It is important to follow the Food Code to ensure that your food is safe for consumption. The fourth type of food safety regulation is the Sanitation Standard Operating Procedures (SSOPs).

SSOPs are designed to ensure that all food production areas are kept clean and sanitary. This includes proper cleaning and sanitation of equipment, surfaces, and utensils.

Finally, the fifth type of food safety regulation is the Prerequisite Programs (PRPs). PRPs are designed to ensure that the food production process is safe and efficient. They include requirements for employee training, pest control, and food safety management.

Understanding food safety regulations is key to running a successful food manufacturing business. By following these regulations, you can ensure that your food products are safe for consumption.

It also helps you to avoid potential fines and penalties for non-compliance. Having a thorough understanding of food safety regulations is also important for protecting your business from potential liability.

Knowing and following the regulations can protect you from costly lawsuits and other legal issues. Finally, understanding food safety regulations can help you to build customer trust and loyalty.

Consumers want to know that the food they purchase is safe and free from contamination. By following food safety regulations, you can ensure that your customers have a safe and enjoyable experience.

Understanding food safety regulations is essential for any food manufacturing business. By familiarizing yourself with the different types of regulations, you can ensure that your food is safe for consumption and protect yourself from potential legal issues.

Developing Comprehensive Quality Control Programs

Quality control is an essential part of food manufacturing. Without proper quality control, food manufacturers risk producing unsafe and substandard products that can negatively impact their customers, their reputation, and their bottom line.

To ensure food safety, manufacturers must develop comprehensive quality control programs that include processes, procedures, and documentation to ensure the quality of their products.

The first step in developing a comprehensive quality control program is to create a quality control plan. This plan should include a detailed overview of the processes and procedures to be followed in order to ensure quality control throughout the manufacturing process.

This plan should include the materials and equipment to be used, the necessary safety protocols, and the processes and procedures to be followed. Once the quality control plan is in place, it is important for food manufacturers to establish a system of quality control checks.

These checks should include daily inspections of all materials used, the equipment used, and the product itself. These inspections should be documented and reviewed regularly to ensure that all processes and procedures are being followed.

In addition to these daily checks, manufacturers should also conduct periodic reviews of their processes and procedures to ensure that they are still effective. In addition to the daily and periodic reviews, manufacturers should also establish a system for responding to customer complaints.

This system should include a procedure for identifying and resolving customer complaints in a timely manner. This system should also include a procedure for investigating customer complaints and taking corrective action, if necessary.

Finally, food manufacturers should establish a system for tracking and analyzing product quality data. This system should include a method for collecting, storing, and analyzing data on product quality.

This system should also include a procedure for responding to, and correcting, any problems that arise. This system should be used to monitor the effectiveness of the quality control processes and procedures and should be reviewed regularly.

Developing a comprehensive quality control program is essential for food manufacturers. By following these best practices, manufacturers can ensure that their products meet the highest standards of quality and safety.

With a comprehensive quality control program in place, manufacturers can ensure that their products are safe and of the highest quality, and can help protect their customers, their reputation, and their bottom line.

Implementing Effective Traceability Procedures

The food industry is one of the most heavily regulated industries in the world, with stringent quality control measures in place to ensure that all food products meet the necessary safety standards.

As a result, effective traceability procedures are an essential part of any food manufacturing business. Traceability is the ability to track the origins of a product from the point of its manufacture to its final destination.

Not only does traceability help you ensure that the food you produce is safe and compliant with regulations, but it also helps you respond quickly and effectively to any potential recalls or quality issues. To ensure that your traceability procedures are as effective as possible, there are a few key steps you should take:

Identify Critical Control Points

Before you can begin to properly track your product, you need to identify all of the critical control points in your production process. These points are where potential contamination risks could occur and should be monitored closely.

Establish a System of Records

Once you’ve identified the critical control points in your production process, you need to establish a system of records that allows you to track the movement of each product throughout the process. This system should include detailed records of when and where each product was produced, stored, and shipped.

Label Each Product

To properly track each product; you should label each item with a unique identifier that allows you to trace it back to its source. This could include a barcode, serial number, or another identifier.

Utilize Automation

Automation can be a great way to streamline your traceability procedures. By using automated systems, you can easily track the movement of each product throughout the process and ensure that all records are up-to-date.

Test Your Procedures

It’s important to periodically test your traceability procedures to ensure that they are working as intended. This could include running a mock recall or randomly checking certain records to make sure they are accurate.

By implementing these steps, you can ensure that your traceability procedures are as effective as possible. This will help you guarantee the safety and quality of your products, as well as respond quickly and effectively to any recalls or quality issues that may arise.

Best Practices for Food Quality Control

Food manufacturing is a complex process that requires careful quality control to ensure safe and high-quality products. From the selection of raw materials to the finished product, quality control is essential throughout the entire process to ensure that the food is safe and meets customer specifications.

Here are some best practices for food manufacturing quality control to help ensure that your products meet regulatory standards and customer expectations.

Establish Quality Standards

A set of quality standards should be established before any product is manufactured. These standards should be based on customer requirements, industry regulations, and any other applicable criteria. Quality standards should include specifications for the raw materials, production processes, packaging, and finished product.

Implement Quality Control Systems

Quality control systems should be established to ensure that quality standards are met. These systems should include processes for testing raw materials, monitoring production processes, and inspecting the finished product. Quality control systems should also include measures to prevent contamination, such as proper storage and handling of raw materials and finished products.

Train Employees

All employees involved in the production process should be trained on proper quality control techniques. This will ensure that everyone is following the same quality standards and that everyone is aware of any potential issues or concerns.

Document Quality Control Measures

Quality control measures should be documented to ensure that they are followed and monitored. This documentation should include the quality standards, quality control system, training, and any other measures taken to ensure product quality.

Monitor Production Processes

Production processes should be monitored to ensure that they are producing consistent results. This could include testing samples from each batch or using automated systems to track production results.

Inspect Finished Products

The finished products should be inspected to ensure that they meet the established quality standards. This could include visual inspection, physical testing, or chemical analysis.

These best practices for food manufacturing quality control can help ensure that your products meet regulatory standards and customer expectations. Following these practices can help you produce safe, high-quality products that meet customer requirements.

How Can Deskera Assist You?

As a manufacturer, you must keep track of your inventory stock. The condition of your inventory has a direct impact on production planning. It also has a direct impact on people and machinery use and capacity utilization.

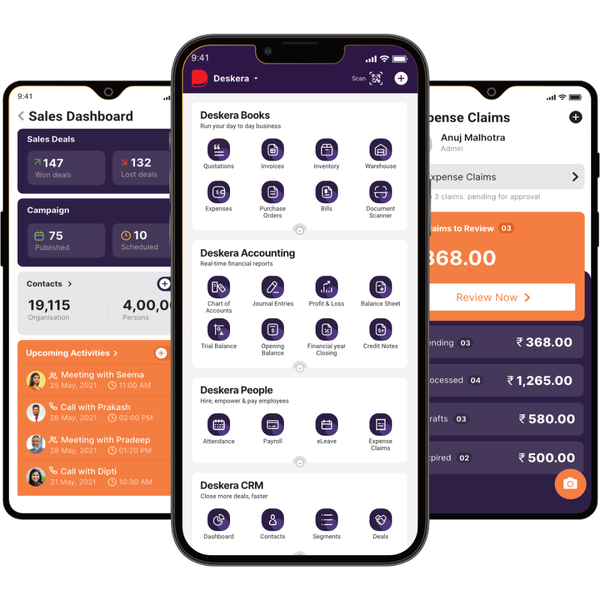

Deskera MRP is the one tool that lets you do all of the above. With Deskera, you can:

- Control production schedules

- Compile a Bill of Materials

- Produce thorough reports

- Make your dashboard

Deskera ERP is a complete solution that allows you to manage suppliers and track supply chain activity in real-time. It also allows you to streamline a range of other company functions.

Deskera Books allows you to manage your accounts and finances better. It helps maintain good accounting standards by automating billing, invoicing, and payment processing tasks.

Deskera CRM is a powerful tool that organizes your sales and helps you close deals rapidly. It enables you to perform crucial tasks like lead generation via email and gives you a comprehensive view of your sales funnel.

Deskera People is a straightforward application for centralizing your human resource management activities. Not only does the technology expedite payroll processing, but it also helps you to handle all other operations such as overtime, benefits, bonuses, training programs, and much more.

Key Takeaways:

- Food manufacturing is a complex process that requires careful quality control to ensure safe and high-quality products.

- Food manufacturing is a complex and highly regulated industry, with a variety of quality control measures in place to ensure the safety and integrity of the product.

- It is essential for food manufacturers to select the highest quality ingredients for their products, as this will ensure the safety and consistency of the final product.

- Quality control systems should be established to ensure that the quality standards are met.

- The finished products should be inspected to ensure that they meet the established quality standards.