As a leader in the manufacturing industry, are you aiming to improve your inventory management practices and secure a competitive edge in the current fast-moving market? If so, you might be interested in learning how real-time inventory tracking can improve your business.

Monitoring inventory levels is essential in a manufacturing environment where efficiency, precision, and reactivity are required. Manufacturing leaders can make educated decisions and promote operational excellence by using real-time inventory management, which provides a system that gives them precise, up-to-the-minute insights into their inventory.

But what are the specific benefits of real-time inventory tracking for manufacturing leaders? In this article, we will explore the top 10 benefits of implementing real-time inventory tracking systems.

By understanding these advantages, you will be equipped with the knowledge and insights to transform your inventory management practices and elevate your manufacturing operations to new heights.

According to recent data from the Manufacturing Institute, inventory management is a significant concern for manufacturers across the United States. 55% of manufacturing leaders identify inventory optimization as one of their top operational priorities.

This statistic reflects the growing recognition of the importance of efficient inventory management in today's competitive landscape.

So, if you're ready to revolutionize your inventory management practices and unlock the full potential of your manufacturing operations, join us on this journey as we explore the 10 key benefits of real-time inventory tracking for manufacturing leaders.

Get ready to embrace a new era of efficiency, accuracy, and value creation in your inventory management processes.

Here is what we shall cover in this post:

- Introduction to Real-Time Inventory Tracking in Manufacturing

- What Is an Inventory Management System?

- How to Choose an Inventory Management System

- 10 Benefits of Real-Time Inventory Tracking for Manufacturing Leaders

- The Limitations of Inventory Management

- How Real-Time Inventory Tracking Works

- Real-Time Reporting and Analytics for Strategic Planning

- Future Trends in Real-Time Inventory Tracking Technology

- How Deskera Can Assist You?

- Conclusion

- Key Takeaways

Introduction to Real-Time Inventory Tracking in Manufacturing

Real-time inventory tracking is a system that allows manufacturers to monitor their inventory levels continuously and accurately. It provides real-time visibility into inventory data, including quantities, locations, and status, through the use of technologies such as barcode scanning, RFID (Radio Frequency Identification), and advanced software systems.

This enables manufacturers to have instant access to information about their inventory, facilitating better decision-making, improved inventory management and enhanced operational efficiency.

- Real-time inventory tracking enhances demand planning and fulfillment processes. By having real-time visibility into inventory levels, manufacturers can accurately forecast demand, optimize production schedules, and align inventory levels with customer demand.

- Real-time inventory tracking systems enable better traceability and quality control. Each inventory item can be tagged or assigned a unique identifier, allowing manufacturers to track its movement throughout the production process.

- Real-time inventory tracking simplifies and streamlines the inventory replenishment process. When inventory levels reach a predetermined threshold, the system can automatically trigger reorder points or notifications, alerting manufacturers to initiate the replenishment process.

What Is an Inventory Management System?

An inventory management system (IMS) is a software application that helps businesses track their inventory levels, orders, sales, and deliveries. IMSs can be used in a variety of industries, including manufacturing, retail, and wholesale.

IMSs provide a number of benefits for businesses, including:

- Improved inventory accuracy: IMSs can help businesses to accurately track their inventory levels, which can help to prevent stockouts and overstocks.

- Reduced costs: IMSs can help businesses to reduce costs by improving inventory accuracy, preventing stockouts, and optimizing inventory levels.

- Improved customer service: IMSs can help businesses to improve customer service by ensuring that they have the right products in stock when customers need them.

- Increased profits: IMSs can help businesses to increase profits by improving inventory accuracy, preventing stockouts, and optimizing inventory levels.

Types of Inventory Management Systems

There are three main types of inventory management systems: manual, periodic, and perpetual.

- Manual inventory management is the simplest type of system. It involves manually tracking inventory levels, ordering new products, and performing inventory counts. This type of system can be time-consuming and error-prone, but it is also the least expensive.

- Periodic inventory management is a more sophisticated system than manual inventory management. It involves using a cycle count system to track inventory levels regularly. This type of system is more accurate than manual inventory management, but it can still be time-consuming and expensive.

- Perpetual inventory management is the most sophisticated type of inventory management system. It uses a computer system to track inventory levels in real-time. This type of system is the most accurate and efficient, but it can also be the most expensive.

Other types include;

Just-in-Time (JIT) Inventory Management Systems: JIT inventory management systems aim to minimize inventory holding costs by maintaining lean inventory levels. These systems focus on delivering materials and products at the exact time they are needed in the production process.

JIT systems require close coordination with suppliers and rely on efficient supply chain management to ensure timely deliveries. While JIT systems help reduce carrying costs, they can be vulnerable to supply chain disruptions and require accurate demand forecasting.

Economic Order Quantity (EOQ) Inventory Management Systems: EOQ inventory management systems aim to find the optimal order quantity that minimizes total inventory costs. The EOQ formula considers factors such as ordering costs, holding costs, and demand rates to determine the most cost-effective order quantity.

EOQ systems help strike a balance between ordering too frequently (incurring high ordering costs) and ordering in large quantities (incurring high holding costs). However, EOQ systems assume stable demand and may not be suitable for businesses with fluctuating or unpredictable demand patterns.

Material Requirements Planning (MRP) Systems: MRP systems are computer-based inventory management systems that use data on demand, production schedules, and bills of materials to calculate the material requirements for manufacturing. MRP systems help ensure that the right materials are available at the right time to meet production needs.

They provide detailed production schedules, generate purchase orders, and facilitate efficient materials planning and procurement. MRP systems are suitable for businesses with complex manufacturing processes and multiple products.

Advanced Planning and Scheduling (APS) Systems: APS systems integrate inventory management with production planning and scheduling to optimize the use of resources and minimize production costs.

These systems consider factors such as capacity constraints, lead times, and order priorities to generate realistic and efficient production schedules. APS systems enable businesses to balance customer demand, inventory levels, and production capacity effectively, improving operational efficiency and customer satisfaction.

Cloud-based Inventory Management Systems: Cloud-based inventory management systems provide businesses with a web-based platform for managing their inventory.

These systems offer the advantage of real-time accessibility from anywhere, as well as automatic backups and data security. Cloud-based systems are scalable, cost-effective, and often integrate with other business systems such as accounting or e-commerce platforms.

Benefits of Automated Inventory Management Systems

Automated IMSs offer several benefits over manual IMSs, including:

- Increased accuracy: Automated IMSs use databases to track inventory levels, orders, sales, and deliveries. This can help to improve inventory accuracy by eliminating the possibility of human error.

- Reduced costs: Automated IMSs can help to reduce costs by reducing the need for manual data entry and by providing more accurate inventory data.

- Improved customer service: Automated IMSs can help to improve customer service by providing real-time inventory data and by automating the order fulfillment process.

- Increased profits: Automated IMSs can help to increase profits by reducing costs and improving customer service.

How to Choose an Inventory Management System

Effective inventory management is crucial for the success of any business. An efficient inventory management system can streamline operations, optimize inventory levels, reduce costs, and improve customer satisfaction.

With numerous inventory management systems available in the market, choosing the right one for your business can be a daunting task.

Define Your Business Needs

Before choosing an inventory management system, it is important to clearly define your business needs and objectives. Assess your current inventory management processes and identify the specific challenges you want to address. Consider factors such as the size of your business, the complexity of your inventory, the number of sales channels, and any industry-specific requirements.

Having a clear understanding of your needs will help you choose a system that aligns with your business goals.

Inventory Tracking and Visibility

One of the primary functions of an inventory management system is to provide accurate and real-time tracking of inventory levels. Ensure that the system you choose offers robust inventory tracking capabilities.

It should allow you to monitor stock levels, track item movements, and provide visibility into stock availability across multiple locations or sales channels. Real-time data synchronization is essential to avoid stockouts or overstocks and enable efficient order fulfillment.

Integration Capabilities

Consider the integration capabilities of the inventory management system with other business systems such as e-commerce platforms, accounting software, and shipping carriers. Seamless integration eliminates manual data entry, reduces errors, and streamlines operations.

Look for systems that offer APIs or have pre-built integrations with popular software to ensure smooth data flow between systems.

Scalability and Flexibility

As your business grows, so will your inventory management needs. Choose a system that is scalable and flexible enough to accommodate your future expansion.

Consider factors such as the maximum number of SKUs the system can handle, the ability to support multiple warehouses or locations, and the ease of adding new users or sales channels. Scalable systems can adapt to changing business requirements without the need for a complete overhaul.

User-Friendliness and Ease of Implementation

An inventory management system should be user-friendly and easy to implement. Look for intuitive interfaces, clear navigation, and a system that aligns with your team's technical capabilities.

Consider whether the system requires extensive training or if it offers onboarding support to help your team get up to speed quickly. A system that is easy to implement and use will save you time and minimize disruption to your operations.

Reporting and Analytics

Comprehensive reporting and analytics capabilities are essential for gaining insights into your inventory performance. The system should offer customizable reports that provide key metrics such as inventory turnover, stock value, and sales trends.

Advanced analytics features, such as demand forecasting and predictive analytics, can help you make data-driven decisions and optimize your inventory levels. Look for systems that offer robust reporting and analytics capabilities tailored to your specific needs.

Support and Customer Service

When selecting an inventory management system, consider the level of support and customer service offered by the provider. Determine their responsiveness, availability, and the channels through which you can seek assistance.

Reliable support is crucial, especially during the implementation process and if any issues or questions arise. Look for providers with a reputation for excellent customer service and ongoing support.

Cost and Return on Investment (ROI)

Finally, consider the cost of the inventory management system and the potential return on investment (ROI) it can deliver. Evaluate the pricing structure, whether it is based on a monthly subscription, per user, or transaction volume.

Calculate the potential cost savings and operational efficiencies the system can provide and assess whether the investment is justified. Consider long-term ROI rather than focusing solely on upfront costs.

10 Benefits of Real-Time Inventory Tracking for Manufacturing Leaders

Real-time inventory tracking has emerged as a valuable tool for manufacturing leaders, providing accurate and up-to-date visibility into inventory levels and movements. By tracking inventory in real-time, manufacturers can improve efficiency, reduce costs, and improve customer satisfaction.

There are many benefits to real-time inventory tracking, including:

1. Improved Accuracy and Inventory Visibility

Accurate inventory management is a critical aspect of running a successful business, especially in the fast-paced world of manufacturing. Real-time inventory tracking has revolutionized inventory management by providing manufacturing companies with improved accuracy and enhanced visibility into their inventory levels.

- Real-time tracking, on the other hand, leverages technology such as barcode scanning, RFID (Radio Frequency Identification), and advanced software systems to capture inventory data automatically and accurately.

- With real-time tracking, businesses can have an accurate and reliable picture of their inventory levels at any given moment. Each inventory item is assigned a unique identifier, allowing for precise tracking and recording of its movement throughout the supply chain.

- This eliminates data entry errors and provides real-time visibility into stock levels, ensuring that businesses have an accurate understanding of their available inventory.

- Accurate inventory data enables businesses to optimize their inventory levels, avoiding stockouts and overstocks.

- They can make informed decisions about procurement, production, and order fulfillment based on actual inventory data, reducing carrying costs and minimizing the risk of obsolescence. Accurate inventory information also supports accurate financial reporting, enabling businesses to calculate the cost of goods sold (COGS) and inventory valuation with precision.

Real-time inventory tracking allows manufacturing companies to have accurate and up-to-date information about their inventory levels at any given moment. Traditional inventory management methods, such as periodic physical counts or manual data entry, are prone to errors and can result in inaccurate inventory records.

2. Enhanced Demand Forecasting and Planning

By capturing sales data in real-time, businesses can track the demand for specific products or SKUs as it happens. This immediate access to sales information helps in understanding trends, identifying patterns, and forecasting demand more accurately.

- Accurate demand forecasts help businesses optimize their inventory levels and minimize the risk of stockouts or overstocks. With real-time data, businesses can precisely determine reorder points, safety stock levels, and lead times, ensuring that inventory is available when needed. By aligning inventory levels with customer demand, businesses can reduce carrying costs, avoid excess inventory, and improve cash flow.

- Real-time inventory tracking also allows businesses to monitor and evaluate the accuracy of their demand forecasts. By comparing actual sales data with forecasted demand, businesses can identify any gaps or discrepancies and refine their forecasting models accordingly.

- This continuous feedback loop improves forecasting accuracy over time, leading to more effective inventory management and improved operational efficiency.

- Real-time inventory tracking enables businesses to adopt agile production planning and procurement strategies. With real-time visibility into inventory levels and demand, businesses can adjust their production schedules and procurement plans in response to fluctuations in customer demand or changes in market conditions.

3. Minimized Stockouts and Disruptions

Inventory management is a critical aspect of any business, and the ability to minimize stockouts and disruptions is essential for ensuring smooth operations and customer satisfaction.

Real-time inventory tracking has emerged as a powerful tool that enables businesses to effectively manage their inventory levels, avoid stockouts, and mitigate disruptions in the supply chain.

A stockout occurs when a business runs out of inventory of a particular product. This can happen for several reasons, such as unexpected demand, supplier delays, or production issues. When a stockout occurs, it can lead to some problems for the business, including:

- Lost sales: When a customer orders a product that is out of stock, they may choose to purchase the product from a competitor instead.

- Damaged reputation: Customers who experience stockouts may be less likely to do business with the company in the future.

- Increased costs: Businesses may have to pay for expedited shipping or other measures to get the product back in stock.

When a supply chain disruption occurs, it can lead to some problems for businesses, including:

- Delays in shipping: Customers may have to wait longer than expected to receive their orders.

- Backorders: Businesses may have to put customers' orders on backorder, which means that they will not receive the product until it is back in stock.

- Increased costs: Businesses may have to pay for expedited shipping or other measures to get the product to customers.

By sharing real-time inventory data with suppliers, businesses can coordinate replenishment activities, align production schedules, and optimize order quantities. This collaboration ensures a smooth flow of goods within the supply chain, minimizing stockouts and disruptions caused by supplier delays or communication gaps.

4. Efficient Inventory Allocation and Replenishment

Efficient inventory allocation and replenishment are critical components of successful inventory management. Businesses strive to optimize their inventory levels by ensuring the right products are available in the right quantities at the right time.

- Real-time inventory tracking has emerged as a valuable tool for businesses to achieve efficient inventory allocation and replenishment. By providing accurate and up-to-date visibility into inventory levels, movements, and trends, real-time inventory tracking offers several benefits that contribute to efficient inventory management.

- By capturing and analyzing real-time data, businesses can allocate inventory based on factors such as proximity to the customer, inventory levels, or shipping requirements.

- Real-time tracking enables businesses to identify the optimal location from which to fulfill each order. They can assess inventory levels at various warehouses or distribution centers and allocate inventory from the most suitable location.

- Automated replenishment triggers streamline the procurement and replenishment processes, reducing the need for manual monitoring and intervention. Businesses can set up reorder points and safety stock levels based on real-time inventory data, ensuring that inventory is replenished before stockouts occur. This eliminates the risk of human error and delays associated with manual reordering.

- Businesses can achieve optimal stock levels without excess inventory by automating replenishment triggers. This helps in reducing carrying costs, minimizing the risk of obsolescence, and improving cash flow.

5. Efficient Order Fulfillment

Real-time inventory tracking enables businesses to efficiently manage order fulfillment processes. With accurate and up-to-date inventory information, businesses can allocate inventory to customer orders based on real-time stock levels. They can prioritize orders based on available inventory, ensuring that customers receive their products on time.

- Real-time tracking also helps businesses optimize their order fulfillment workflows. They can monitor order status, track inventory movements, and proactively address any delays or issues in the fulfillment process. By having real-time visibility into the status of each order, businesses can take corrective actions promptly, reducing the risk of order backlogs or missed delivery deadlines.

- If certain items are low in stock, businesses can ensure that orders containing those items are processed with high priority to avoid stockouts. This helps in meeting customer expectations and delivering orders within the promised timeframe.

- Moreover, real-time tracking facilitates efficient order routing. Businesses can use real-time data to identify the closest warehouse or distribution center with the required inventory, optimizing the shipping process and reducing transit times. This ensures faster order fulfillment and enhances overall operational efficiency.

Additionally, real-time inventory tracking facilitates accurate order promise. When customers place orders, businesses can provide accurate delivery estimates based on real-time inventory availability. This reduces the risk of overpromising and improves customer satisfaction by ensuring that delivery expectations are met.

6. Proactive Inventory Planning

Real-time inventory tracking empowers businesses to adopt proactive inventory management practices. By having accurate and real-time visibility into inventory levels, businesses can proactively manage their stock levels to meet customer demands.

With real-time tracking, businesses can set up automated alerts or triggers based on predefined inventory thresholds. When inventory levels reach a certain point, businesses can receive notifications to initiate replenishment activities. This proactive approach ensures that businesses can replenish inventory before stockouts occur, reducing the risk of disruptions in customer order fulfillment.

There are two main approaches to inventory management: reactive and proactive. Reactive inventory management is based on the idea of waiting until you run out of an item before ordering more. This can lead to stockouts, which can damage your reputation and lose you customers.

Proactive inventory management, on the other hand, is based on the idea of planning and ordering inventory based on expected demand. This can help you avoid stockouts and keep your customers happy.

One of the best ways to implement proactive inventory management is to use real-time inventory tracking. Real-time inventory tracking allows you to see exactly how much inventory you have on hand at all times. This information can be used to forecast demand and make accurate ordering decisions.

There are many benefits to using real-time inventory tracking for proactive inventory planning. These benefits include:

- Reduced stockouts: Real-time inventory tracking can help you avoid stockouts by giving you a clear picture of your inventory levels. This allows you to order more inventory before you run out, which can help you keep your customers happy.

- Improved customer service: Real-time inventory tracking can help you improve customer service by giving you the ability to quickly and accurately respond to customer inquiries about product availability. This can help you build customer loyalty and boost sales.

- Increased profits: Real-time inventory tracking can help you increase profits by reducing costs associated with stockouts and lost sales. It can also help you optimize your inventory levels, which can lead to increased sales and decreased costs.

If you are looking for a way to improve your inventory management and boost your bottom line, real-time inventory tracking is a great option. It can help you implement proactive inventory planning, which can lead to reduced stockouts, improved customer service, and increased profits.

Here are some additional tips for implementing proactive inventory planning:

- Set up a forecasting system: A forecasting system can help you predict demand for your products. This information can be used to determine how much inventory you need to order.

- Set reorder points: A reorder point is the level at which you need to order more inventory. This level should be based on your forecasted demand and your lead time (the time it takes to receive new inventory).

- Use a perpetual inventory system: A perpetual inventory system tracks inventory levels in real-time. This information can be used to track inventory usage and identify any potential problems.

- Conduct regular inventory audits: An inventory audit is a physical count of your inventory. This should be done regularly to ensure that your inventory records are accurate.

- Use technology to your advantage: There are several software programs and mobile apps that can help you with inventory management. These tools can make it easier to track inventory levels, forecast demand, and place orders.

7. Avoids Fluctuations in Inventory Levels

Real-time inventory tracking aids in preventing the accumulation of surplus products in your warehouses. Naturally, you can save a tonne of money by doing this, but there are other advantages to using real-time inventory counts to reduce your stock.

- Having too much inventory restricts your ability to move nimbly as a merchant. You have no control over when it is purchased or the drawbacks you choose to accept. A more efficient method will give you more control over your inventory.

- A just-in-time inventory method is suggested by experts to improve order fulfillment's precision and effectiveness. This entails simply retaining items in your storage facilities that will be needed immediately. By minimizing surplus stock, only keeping what is urgently required reduces expenses.

- The disadvantage of using this method is that it necessitates a highly precise grasp of the company's stock levels and client needs. For instance, a business with too low inventory will struggle to fulfill an excessive demand by trying to use its supply as efficiently as possible, which could lead to stockouts.

- You shouldn't have to decide between paying to hold more inventory and being unable to satisfy customer demands due to a dearth of inventory. To ensure customer happiness and effective warehouse management, you must be able to predict how your inventory may change depending on seasonality and market demand for specific commodities.

- To assist you deliver consistent service, real-time inventory management may show you how inventory levels change with the seasons or in-demand items.

8. Improved customer experience

An organized and precise inventory management system can enhance the client experience. Customers are happier when orders are filled by businesses swiftly and accurately.

This degree of customer care can strengthen the bond between the company and its clients by fostering more customer loyalty and trust. As more people utilize your items, this contributes to the development of a more positive brand image and may result in higher earnings.

- Customers now anticipate a reasonably predictable fulfillment process. You must exceed their expectations if you want to earn their satisfaction.

- The bar is raised for smaller companies attempting to participate in the e-commerce sector by that criteria. Inventory management is essential if you want to succeed in your endeavor.

- You want to make sure that every time a customer orders from you, they have the same delivery experience. Monitoring your inventory in real time can assist you in giving your consumers the consistent service they demand.

- You might always have too much or not enough stock without a dependable inventory management system. Your delivery schedule depends on having enough merchandise to fulfill customer orders as soon as they come in. Backorders may cause your delivery to be delayed if your stock is too low. From there, you'll probably lose business.

- You provide customers with a better customer experience if you use real-time inventory tracking to provide a more reliable fulfillment service. That will probably increase revenue, bring in devoted clients, and establish your brand's credibility.

9. Improved Supplier Management and Relationships

Real-time inventory tracking promotes enhanced collaboration with suppliers, leading to streamlined supply chain operations. By sharing real-time inventory data, businesses can enable their suppliers to gain visibility into their inventory requirements and optimize their production and delivery processes.

Real-time tracking allows businesses to communicate their inventory needs more accurately and promptly to suppliers. Suppliers can access real-time inventory data to understand the demand fluctuations and adjust their production schedules and order fulfillment processes accordingly.

This proactive collaboration helps in avoiding stockouts, reducing lead times, and improving overall supply chain responsiveness.

Moreover, real-time tracking enables businesses to monitor supplier performance and compliance. By tracking supplier delivery times, accuracy, and quality, businesses can identify any potential issues and address them proactively. This helps in maintaining a reliable supplier network, reducing supply chain disruptions, and ensuring smooth operations.

10. Improved Data Security

Users of modern inventory management systems can control who has access to a company's inventory.

- The potential costs of a data breach are reduced thanks to these rights. The confidentiality of a company's internal activities from suppliers and service employees is further ensured by inventory management systems. This concentration of knowledge can act as a defense against cyberattacks and improve the effectiveness of mistake troubleshooting.

- Data security is improved by inventory management systems, but data visibility for the company's leadership team is also increased.

- Leaders may make more educated company decisions with fewer mistakes that could waste time or money when there is greater data visibility. To detect any disparities in inventory counts, a warehouse manager, for instance, can monitor what merchandise enters and exits the warehouse.

The Limitations of Inventory Management

Effective inventory management helps businesses maintain optimal stock levels, reduce carrying costs, and meet customer demand efficiently. However, like any business process, inventory management also has its limitations and challenges that need to be understood and addressed.

Lack of Real-Time Visibility

One of the primary limitations of inventory management is the lack of real-time visibility into inventory levels, locations, and movements. Traditional inventory management methods often rely on manual counts, periodic updates, or batch processing, which can result in outdated and inaccurate inventory data.

This lack of real-time visibility poses challenges in making informed decisions regarding order fulfillment, production planning, and procurement.

To overcome this limitation, businesses can leverage technology solutions such as barcode scanning, RFID (Radio Frequency Identification), or advanced inventory management software. These tools enable real-time tracking of inventory, providing accurate and up-to-date visibility. By implementing real-time inventory tracking systems, businesses can make data-driven decisions and enhance the efficiency of their inventory management processes.

Forecasting and Demand Uncertainty

Accurate demand forecasting is crucial for effective inventory management. However, forecasting demand is challenging due to various factors, including changing customer preferences, market trends, and external influences such as economic conditions or natural disasters.

This demand uncertainty poses a limitation to inventory management, as businesses must strike a balance between carrying enough inventory to meet customer demand and minimizing the risk of excess stock.

To address this limitation, businesses can adopt demand forecasting models that incorporate historical sales data, market research, and statistical analysis. Advanced forecasting techniques, such as machine learning algorithms or predictive analytics, can also be employed to improve the accuracy of demand forecasts.

Additionally, businesses can establish strong relationships with suppliers and implement agile supply chain practices to respond quickly to changes in demand.

Carrying Costs and Obsolescence

Carrying costs, which include expenses such as warehousing, storage, insurance, and depreciation, is a significant consideration in inventory management. The longer inventory sits in storage, the higher the carrying costs become. Moreover, there is a risk of inventory becoming obsolete or outdated, leading to financial losses.

To mitigate the impact of carrying costs and obsolescence, businesses can implement inventory optimization techniques. These techniques involve analyzing demand patterns, lead times, and other factors to determine the optimal stock levels that minimize carrying costs while ensuring sufficient inventory availability.

Just-in-time (JIT) or lean inventory management strategies can also be employed to reduce carrying costs by minimizing excess inventory and improving supply chain efficiency.

Supply Chain Disruptions

Supply chain disruptions, such as natural disasters, labor strikes, or supplier issues, can significantly impact inventory management. These disruptions can lead to stockouts, delays in order fulfillment, and increased costs. Managing inventory effectively in the face of supply chain disruptions is a challenge that businesses must address.

To mitigate the impact of supply chain disruptions, businesses can develop contingency plans and alternative sourcing strategies. Diversifying suppliers and maintaining strong relationships with multiple vendors can help mitigate the risk of disruptions.

Additionally, businesses can implement supply chain visibility tools to monitor and track inventory in real time, enabling proactive decision-making and timely response to disruptions.

Lead Time Variability

Lead time refers to the time it takes for suppliers to deliver products after an order is placed. Variability in lead times can pose challenges to inventory management, especially when demand is time-sensitive or unpredictable.

Longer lead times can result in the need for higher safety stock levels to prevent stockouts. On the other hand, shorter lead times may allow for lower safety stock levels but require more frequent ordering and potentially increase procurement costs.

To address lead time variability, businesses can establish strong relationships with suppliers, negotiate shorter lead times, and implement vendor-managed inventory (VMI) programs. VMI involves the supplier taking responsibility for maintaining inventory levels at the customer's location, reducing lead time and inventory carrying costs.

Additionally, implementing lean inventory practices, such as just-in-time (JIT) or kanban systems, can help reduce lead times by optimizing production and supply chain processes, improving overall efficiency, and minimizing the need for excessive inventory levels.

Bullwhip Effect

The bullwhip effect is a phenomenon in supply chain management where small fluctuations in demand at the end-customer level can result in amplified fluctuations in orders and inventory levels further upstream in the supply chain. This effect occurs due to delays in information flow, communication gaps, and order batching practices.

The bullwhip effect can lead to inventory imbalances, excess inventory, and inefficiencies in the supply chain. As the demand signal becomes distorted and amplified, businesses may face challenges in accurately matching supply with demand, resulting in inventory holding costs and potential stockouts.

To mitigate the bullwhip effect, businesses can implement the following strategies:

- Improve communication and information sharing among supply chain partners to minimize information delays and distortions.

- Implement collaborative planning, forecasting, and replenishment (CPFR) practices to enhance coordination and reduce order variability.

- Adopt lean principles and just-in-time (JIT) inventory management to reduce order batching and minimize excess inventory.

- Utilize advanced technology and data analytics to gain real-time visibility into supply chain dynamics and demand patterns.

By addressing the bullwhip effect, businesses can streamline their supply chain operations, reduce inventory fluctuations, and enhance overall efficiency.

How Real-Time Inventory Tracking Works

Real-time inventory tracking is a system that allows businesses to track their inventory levels in real-time. This means that businesses can see exactly how many items they have in stock, where those items are located, and when they need to be restocked. Real-time inventory tracking can be a valuable tool for businesses of all sizes, as it can help them to improve their efficiency, profitability, and customer service.

There are several different ways to implement real-time inventory tracking. Some businesses use barcode scanners to scan items as they are received or sold. Others use radio frequency identification (RFID) tags to track the movement of items throughout their warehouse or distribution center. Still, others use a combination of barcode scanners and RFID tags.

Data Capture Technologies

Real-time inventory tracking relies on various data capture technologies to collect and record inventory information accurately and instantaneously. The following technologies and components are key to the functioning of real-time inventory tracking systems:

Barcoding and Scanning: Barcoding is a widely used technology in real-time inventory tracking. Each product is assigned a unique barcode containing essential information such as the product code, description, and other relevant details. Barcodes can be easily scanned using handheld barcode scanners or mobile devices equipped with barcode scanning capabilities.

When an item is received, picked, or sold, the barcode is scanned, and the information is instantly transmitted to the inventory management system. This real-time data capture ensures accurate and up-to-date inventory tracking.

RFID (Radio Frequency Identification): RFID technology utilizes radio waves to track and identify objects. It consists of RFID tags attached to individual items or containers and RFID readers that capture and transmit the tag's information wirelessly.

RFID tags can store more information than barcodes and do not require line-of-sight scanning. As a result, RFID enables faster and more automated inventory tracking. When an item with an RFID tag passes near an RFID reader, the reader detects and captures the tag's information, including its unique identifier and other data. This information is then transmitted to the inventory management system, providing real-time visibility of the item's location and status.

RFID technology is particularly useful in scenarios where fast and automated tracking is required, such as in high-volume warehouses or distribution centers.

IoT (Internet of Things) Sensors: The Internet of Things (IoT) refers to a network of interconnected devices embedded with sensors, software, and connectivity capabilities. In the context of real-time inventory tracking, IoT sensors can be used to monitor and collect data on various parameters related to inventory, such as temperature, humidity, vibration, or movement.

IoT sensors provide continuous real-time monitoring of inventory conditions. For example, in industries like pharmaceuticals or food, where temperature control is crucial, IoT sensors can alert inventory managers if the temperature deviates from the required range. This allows for proactive measures to be taken to prevent product spoilage or damage.

The data collected by IoT sensors is transmitted to the inventory management system through a network connection, enabling businesses to monitor and respond to inventory conditions in real time.

Cloud-Based Inventory Management Software: Real-time inventory tracking systems rely on cloud-based inventory management software to store, process, and analyze the data collected from various sources. Cloud-based software offers several advantages, including scalability, accessibility, and real-time synchronization of data across multiple devices or locations.

With cloud-based inventory management software, businesses can access real-time inventory data from anywhere, using any internet-connected device. This flexibility allows for quick decision-making and facilitates collaboration among different stakeholders in the supply chain.

Additionally, cloud-based software can leverage advanced analytics and reporting capabilities to provide insights into inventory trends, demand forecasting, and optimization opportunities.

These data capture technologies enable businesses to collect real-time inventory data with speed and accuracy, eliminating the need for manual data entry and reducing the risk of errors.

Inventory Management Software

Real-time inventory tracking relies on robust inventory management software to collect, process, and store inventory data. The software acts as a central hub that integrates data from various sources and provides real-time visibility into inventory levels, locations, and movements.

Inventory management software typically includes features such as:

- Inventory Database: The software maintains a comprehensive database that stores information about each product, including SKU (Stock Keeping Unit), description, location, quantity, and other relevant attributes.

- Real-Time Updates: As inventory data is captured through barcode scanning, RFID, IoT sensors, or mobile devices, the inventory management software updates the inventory database in real-time, ensuring accurate and up-to-date information.

- Inventory Tracking: The software tracks the movement of inventory items across different locations, such as warehouses, distribution centers, or retail stores. It provides visibility into stock transfers, shipments, or sales, allowing businesses to monitor inventory levels and make informed decisions.

- Reporting and Analytics: Inventory management software offers reporting and analytics capabilities that allow businesses to gain insights into inventory performance, demand patterns, stock turnover, and other key metrics. These insights help businesses make data-driven decisions and optimize their inventory management strategies.

Integration with Inventory Management Software

Real-time inventory tracking systems integrate with inventory management software or enterprise resource planning (ERP) systems to store, process, and manage inventory data. The software acts as a centralized hub for inventory information, providing real-time visibility into stock levels, locations, movements, and other relevant data.

- When inventory data is captured through barcode scanning, RFID, IoT devices, or mobile applications, it is transmitted to the inventory management software in real time. The software updates the inventory records, reflecting the changes in stock levels and locations immediately.

- Integration with inventory management software allows businesses to access real-time inventory information from any location or device with an Internet connection. This real-time visibility enables businesses to make informed decisions regarding order fulfillment, replenishment, production planning, and other inventory-related processes.

Connectivity and Data Transmission

Real-time inventory tracking relies on seamless connectivity and data transmission between the data capture technologies and the inventory management software. The captured inventory data needs to be transmitted quickly and accurately to the software for real-time updates.

This connectivity can be achieved through various means:

- Wired Connections: Barcode scanners or RFID readers can be connected to the inventory management software via wired connections, such as USB or Ethernet cables. This ensures fast and reliable data transmission.

- Wireless Connections: Wireless technologies, such as Wi-Fi or Bluetooth, can be used for data transmission. Mobile devices, equipped with inventory management apps, can connect to the software wirelessly, enabling real-time updates from anywhere within the facility.

Cloud-Based Infrastructure

Real-time inventory tracking systems often utilize cloud-based infrastructure to store and process inventory data. Cloud computing provides a scalable and secure platform for managing large volumes of data in real time.

Cloud-based inventory management systems store inventory data in a centralized database, accessible from anywhere with an internet connection. This ensures that inventory information is always up-to-date and synchronized across different locations and devices.

Additionally, cloud-based infrastructure offers benefits such as data backup and disaster recovery, scalability to accommodate changing business needs, and the ability to integrate with other business systems and third-party applications.

Implementing Real-Time Inventory Tracking

Real-time inventory tracking has become an essential tool for businesses seeking to optimize their inventory management processes. By providing accurate and up-to-date visibility into inventory levels, locations, and movements, real-time tracking enables businesses to make data-driven decisions, reduce costs, and enhance operational efficiency.

Define Inventory Management Objectives

Before implementing real-time inventory tracking, it is crucial to define clear objectives and goals for the inventory management process. This involves understanding the specific challenges and pain points faced by the business and identifying the desired outcomes of implementing real-time tracking.

Common inventory management objectives include:

- Optimizing inventory levels to minimize carrying costs while ensuring adequate stock availability.

- Improving order fulfillment rates and reducing stockouts.

- Enhancing demand forecasting accuracy.

- Streamlining supply chain operations.

- Increasing overall operational efficiency.

By defining specific objectives, businesses can align their real-time inventory tracking implementation strategy with their broader inventory management goals.

Researching and Selecting the Right Solution

Once you have identified your business needs, the next step is to research and select the right real-time inventory tracking solution. There are several factors to consider during this process:

- Technology Options: Evaluate the available technologies such as barcode scanning, RFID, IoT devices, or a combination of these. Consider the pros and cons of each technology concerning your business requirements, such as the type of products, the size of the inventory, and the complexity of the supply chain.

- Integration Capability: Assess the integration capabilities of the inventory tracking solution with your existing systems, such as your inventory management software, enterprise resource planning (ERP) system, or other relevant platforms. Seamless integration ensures smooth data flow between systems and avoids data silos.

- Scalability: Consider the scalability of the solution to accommodate your business growth. Ensure that the solution can handle increasing inventory volumes, multiple locations, and additional functionalities as your business expands.

- User-Friendliness: Evaluate the usability and user interface of the solution. The system should be intuitive and easy to navigate, allowing your team to quickly adapt and utilize real-time inventory tracking capabilities.

- Vendor Reputation and Support: Research the reputation and track record of potential vendors. Look for customer reviews, case studies, and references to assess the vendor's expertise, reliability, and customer support capabilities.

It is advisable to involve key stakeholders from different departments, such as operations, IT, and procurement, in the evaluation process to gather diverse perspectives and ensure that the chosen solution meets the needs of all stakeholders.

Assess Current Inventory Management Processes

The next step is to assess the existing inventory management processes and systems in place. This includes evaluating the current methods of tracking inventory, data collection processes, software systems used, and the level of automation.

Businesses should examine how inventory data is currently captured, recorded, and updated. This assessment helps identify any existing gaps, inefficiencies, or limitations that can be addressed through the implementation of real-time tracking.

It is essential to involve key stakeholders, including inventory managers, warehouse personnel, IT professionals, and other relevant team members, in the assessment process. Their insights and feedback can provide valuable information about pain points and opportunities for improvement.

Choose the Right Technology Solution

Selecting the appropriate technology solution is a critical aspect of implementing real-time inventory tracking. There are several options available, and the choice depends on factors such as the business's size, industry, complexity of inventory operations, and budget.

When selecting a technology solution, businesses should consider factors such as scalability, ease of integration with existing systems, user-friendliness, vendor support, and the ability to customize the solution to their specific needs.

Data Architecture and Integration

Establishing a robust data architecture is crucial for implementing real-time inventory tracking. Define the data model and data flow required to support real-time tracking and ensure data consistency and accuracy throughout the system.

Determine the key data elements to be captured, such as product identifiers, quantities, locations, timestamps, and any additional attributes relevant to your inventory management processes. Design a data schema that accommodates the necessary fields and allows for efficient data retrieval and analysis.

Real-Time Reporting and Analytics for Strategic Planning

In the realm of inventory management, real-time reporting and analytics play a crucial role in driving strategic planning and decision-making. With the rapid pace of business and the ever-changing dynamics of supply chains, organizations need access to accurate and up-to-date information to optimize their inventory levels, streamline processes, and ensure customer satisfaction.

Strategic planning in inventory management involves setting goals, defining inventory policies, and making informed decisions to optimize inventory levels and meet customer demands. Real-time reporting and analytics are vital tools in this process, enabling organizations to:

Monitor Key Performance Indicators (KPIs): Real-time reporting allows organizations to track and monitor essential KPIs such as inventory turnover, stock levels, stockouts, lead times, and order fulfillment rates. This immediate visibility into KPIs enables proactive decision-making and facilitates the identification of issues or opportunities in inventory management.

Identify Trends and Patterns: Analytics provides organizations with the ability to analyze historical and real-time data to identify trends, patterns, and correlations. By leveraging advanced analytics techniques such as data visualization, predictive modeling, and machine learning, organizations can uncover insights that drive strategic decision-making.

This helps identify seasonality, demand patterns, and potential inventory risks, supporting effective inventory planning and forecasting.

Optimize Inventory Levels: Real-time reporting and analytics enable organizations to optimize inventory levels based on demand patterns, lead times, and customer expectations. By monitoring real-time data on inventory levels and sales, organizations can make data-driven decisions to avoid overstocking or stockouts. This leads to improved inventory turnover, reduced carrying costs, and increased profitability.

Improve Supply Chain Efficiency: Real-time reporting and analytics provide insights into supply chain performance, allowing organizations to identify bottlenecks, delays, or inefficiencies. By analyzing real-time data on supplier performance, production lead times, and transportation metrics, organizations can optimize their supply chain processes, streamline operations, and enhance overall efficiency.

Real-Time Performance Metrics and Reporting

Real-time reporting provides instant visibility into key performance indicators (KPIs), while real-time metrics enable organizations to track and analyze performance in real time. Real-time performance metrics and reporting play a crucial role in driving organizational success. Here are some key real-time performance metrics in inventory management:

Inventory Turnover Ratio

The inventory turnover ratio is a fundamental performance metric that measures the efficiency of inventory management. It indicates how quickly a company can sell its inventory and replace it with new stock. The formula for calculating the inventory turnover ratio is:

Inventory Turnover Ratio = Cost of Goods Sold / Average Inventory

A high inventory turnover ratio signifies that inventory is being sold quickly, indicating effective management and efficient use of resources. On the other hand, a low inventory turnover ratio may indicate excess inventory or slow-moving items.

By monitoring the inventory turnover ratio in real time, organizations can identify trends and patterns, adjust purchasing and production strategies, and optimize their inventory levels to match customer demand.

Fill Rate

The fill rate is a metric that measures the percentage of customer orders that can be fulfilled from existing inventory. It reflects the organization's ability to meet customer demands promptly. The fill rate is calculated using the following formula:

Fill Rate = (Number of Orders Fulfilled in Full / Total Number of Orders Placed) x 100

A high fill rate indicates effective inventory management and customer satisfaction. It means that the organization has the right products available when customers place orders, minimizing the need for backorders or delays.

Real-time monitoring of the fill rate enables organizations to identify potential stockouts, assess supply chain performance, and take proactive measures to maintain high fill rates, such as adjusting replenishment strategies or collaborating with suppliers to ensure timely deliveries.

Stockout Rate

The stockout rate measures the frequency or percentage of instances where a product is out of stock when a customer places an order. It is a critical metric for organizations to monitor, as stockouts can lead to dissatisfied customers, missed sales opportunities, and potential damage to the brand's reputation. The stockout rate can be calculated using the following formula:

Stockout Rate = (Number of Stockouts / Total Number of Orders Placed) x 100

Real-time monitoring of the stockout rate allows organizations to identify potential supply chain disruptions, forecast inaccuracies, or issues with inventory replenishment.

By analyzing the stockout rate in real-time, organizations can take immediate corrective actions, such as expediting orders, adjusting safety stock levels, or improving demand forecasting accuracy, to minimize stockouts and ensure a seamless customer experience.

Order Cycle Time

The order cycle time measures the time it takes to fulfill a customer order, from the moment the order is placed to the moment it is delivered. It is an essential metric for assessing the efficiency of order processing and fulfillment operations.

The order cycle time can be broken down into various stages, including order processing, picking, packing, and shipping. Real-time monitoring of the order cycle time allows organizations to identify bottlenecks or inefficiencies in their order fulfillment processes.

By reducing the order cycle time, organizations can improve customer satisfaction, increase order accuracy, and enhance overall operational efficiency.

Leveraging Analytics for Actionable Insights

Analytics in inventory management refers to the process of collecting, analyzing, and interpreting data to gain insights and drive decision-making. It plays a pivotal role in helping organizations make sense of their inventory-related data, uncover patterns and trends, and identify areas for improvement.

Leveraging analytics in inventory management involves employing various techniques to extract actionable insights from the data. Here are some key analytics techniques that can be applied:

Descriptive Analytics

Descriptive analytics is the foundation of inventory management analytics. It focuses on summarizing historical data to provide insights into past performance. Descriptive analytics techniques include data visualization, dashboards, and reports that help organizations understand trends, patterns, and anomalies in their inventory data.

Here are some key aspects of descriptive analytics in inventory management:

- Data Visualization: Data visualization techniques, such as charts, graphs, and heatmaps, enable organizations to visually represent their inventory data. This makes it easier to identify trends, spot outliers, and gain a comprehensive understanding of inventory performance. Data visualization helps stakeholders quickly interpret large amounts of data and make informed decisions.

- Dashboards: Dashboards provide a consolidated view of key performance indicators (KPIs) related to inventory management. They allow organizations to monitor metrics such as inventory turnover, fill rate, stockout rate, and carrying costs in real-time. Dashboards provide a holistic view of inventory performance and highlight areas that require attention or improvement.

- Reports: Reports provide detailed insights into inventory performance over specific periods. They can include metrics such as sales trends, demand patterns, stockout occurrences, and inventory valuation. Reports help organizations analyze historical data, identify areas of improvement, and guide future inventory management strategies.

Predictive Analytics

Predictive analytics involves using statistical modeling and machine learning algorithms to forecast future inventory demand and identify potential risks and opportunities. By analyzing historical data and external factors such as market trends and seasonality, organizations can make accurate predictions about future demand.

Here are some key aspects of predictive analytics in inventory management:

- Demand Forecasting: Predictive analytics helps organizations forecast future demand patterns by analyzing historical sales data, market trends, customer behavior, and other relevant factors. Accurate demand forecasting enables organizations to optimize inventory levels, reduce stockouts, and improve customer satisfaction.

- Seasonality Analysis: Many businesses experience seasonality in their inventory demand, where certain products have higher demand during specific periods. Predictive analytics helps identify seasonal patterns and enables organizations to plan inventory levels and production schedules accordingly. By anticipating seasonal fluctuations, organizations can optimize inventory and avoid overstocking or stockouts.

- Risk Assessment: Predictive analytics can identify potential risks and disruptions in the supply chain that may impact inventory availability. By analyzing data related to supplier performance, lead times, and external factors such as weather events or geopolitical changes, organizations can proactively mitigate risks and ensure uninterrupted supply.

Prescriptive Analytics

Prescriptive analytics goes beyond descriptive and predictive analytics by providing recommendations on the best course of action. It uses optimization algorithms and simulation techniques to identify the most effective inventory management strategies.

Prescriptive analytics takes into account various constraints and objectives, such as service level targets, lead times, and production capacity, to determine optimal inventory policies.

By leveraging prescriptive analytics, organizations can:

- Optimize reorder points and reorder quantities to minimize stockouts and reduce excess inventory.

- Determine the optimal safety stock levels to achieve desired service levels.

- Optimize inventory allocation across different locations or channels.

- Optimize production planning to align with demand forecasts and minimize production costs.

Prescriptive analytics empowers organizations to make informed decisions about inventory management strategies, balancing customer service levels with cost efficiency.

Future Trends in Real-Time Inventory Tracking Technology

As technology continues to advance at a rapid pace, new trends are emerging in real-time inventory tracking that promises to further enhance efficiency, accuracy, and responsiveness in inventory management.

Artificial Intelligence (AI) and Machine Learning (ML)

Artificial intelligence (AI) and machine learning (ML) algorithms are revolutionizing inventory management by enabling predictive and prescriptive analytics.

In the future, AI and ML will play an even more significant role in real-time inventory tracking. These technologies can analyze vast amounts of data, including historical sales data, market trends, and customer behavior, to forecast demand, optimize inventory levels, and automate decision-making processes.

AI-powered algorithms can continuously learn from data patterns, adapt to changing market conditions, and provide real-time recommendations for inventory replenishment, order allocation, and supply chain optimization. For example, AI can dynamically adjust safety stock levels based on demand volatility, lead times, and customer service level targets.

ML algorithms can also identify patterns of fraudulent activities, such as inventory shrinkage or theft, and trigger immediate alerts to prevent losses.

Blockchain Technology

Blockchain technology, with its distributed and immutable ledger, holds great promise for enhancing transparency and trust in real-time inventory tracking. By leveraging blockchain, organizations can create a secure and auditable record of every transaction and movement within the supply chain. This ensures that all parties involved have access to the same information, reducing discrepancies, disputes, and fraud.

Blockchain technology can improve traceability in supply chains, particularly for industries that require strict compliance, such as pharmaceuticals and food. Real-time inventory tracking powered by blockchain can provide end-to-end visibility, enabling organizations to track the origin, movement, and quality of products in real time.

This enhances product authenticity, reduces the risk of counterfeit goods, and ensures regulatory compliance.

Advanced Analytics and Predictive Insights

The future of real-time inventory tracking will involve advanced analytics techniques that go beyond descriptive analytics. Organizations will leverage sophisticated algorithms and data models to gain predictive insights into inventory demand, supply chain disruptions, and customer behavior.

Advanced analytics techniques, such as natural language processing (NLP) and sentiment analysis, can extract valuable information from unstructured data sources, including customer reviews, social media, and online forums. This allows organizations to capture real-time feedback and sentiment about their products, enabling them to make informed decisions about inventory management and product development.

Moreover, predictive analytics models will incorporate external data sources, such as weather patterns, economic indicators, and competitor information, to improve demand forecasting accuracy. By accurately predicting future demand, organizations can optimize inventory levels, reduce stockouts, and improve customer satisfaction.

Cloud Computing and Big Data Analytics

Cloud computing and big data analytics have already transformed many aspects of business operations, and inventory management is no exception. Cloud-based inventory management systems allow organizations to store and access inventory data in real time from anywhere, enabling seamless collaboration and scalability.

Big data analytics can process and analyze massive amounts of inventory data to identify trends, patterns, and anomalies. With the integration of cloud computing and big data analytics, organizations can leverage real-time inventory data to gain actionable insights, optimize inventory levels, and improve supply chain efficiency.

Predictive Analytics and Demand Sensing

The ability to accurately forecast customer demand is crucial for effective inventory management. Predictive analytics and demand sensing technologies leverage historical sales data, market trends, social media, weather data, and other external factors to forecast demand with greater accuracy.

These technologies can detect demand signals in real-time, allowing organizations to adjust inventory levels and production plans accordingly. By leveraging predictive analytics and demand sensing, organizations can optimize inventory levels, reduce stockouts, and improve customer satisfaction.

Robotics and Automation

The integration of robotics and automation in inventory management is a growing trend. Automated systems can perform tasks such as picking, packing, and replenishment with greater speed and accuracy, reducing human errors and labor costs.

Robotics can be combined with real-time inventory tracking technology to create smart warehouses where robots navigate autonomously, picking and moving inventory items based on real-time demand.

How Deskera Can Assist You?

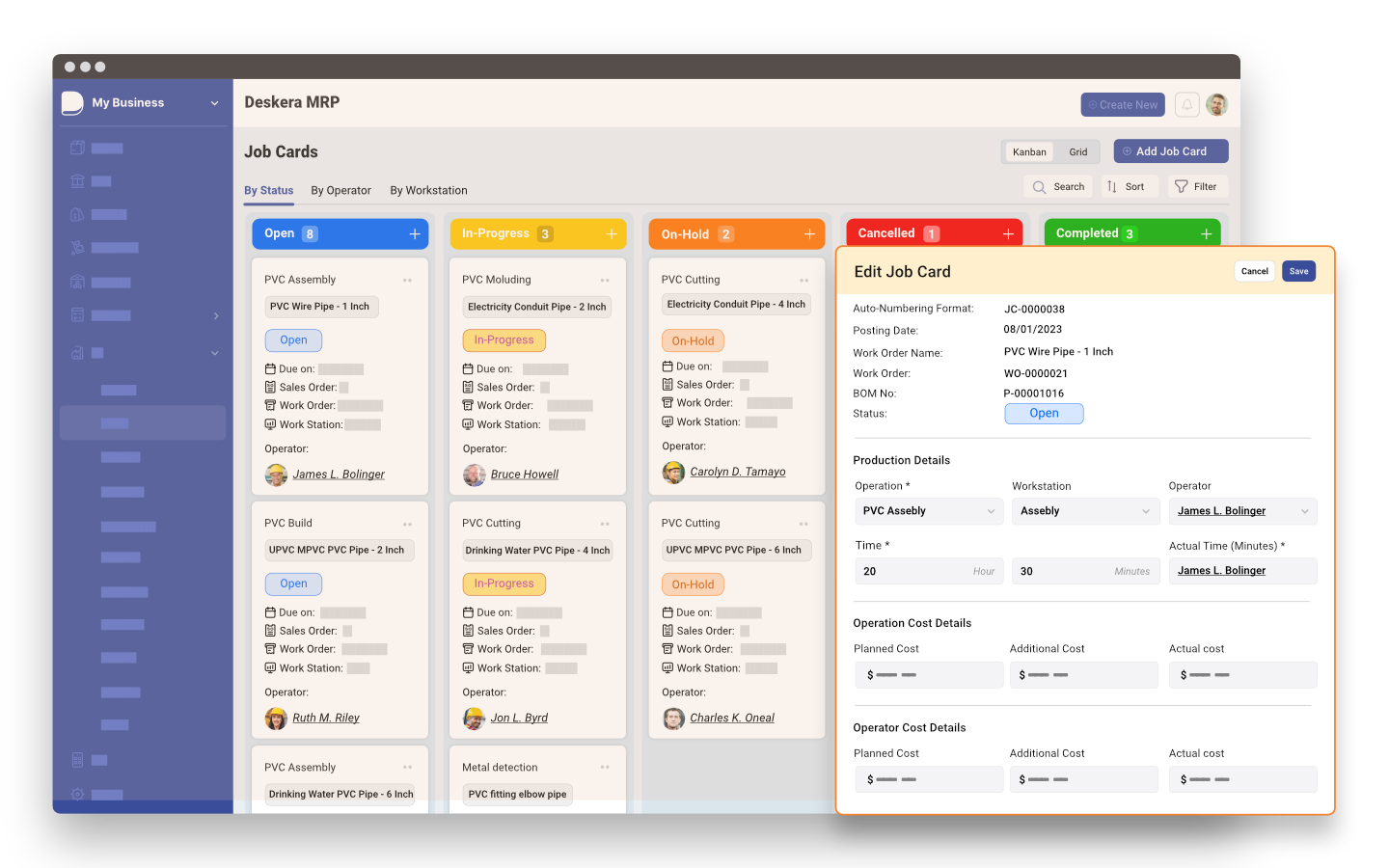

Deskera ERP and MRP system can help you:

- Manage production plans

- Maintain Bill of Materials

- Generate detailed reports

- Create a custom dashboard

Deskera ERP is a comprehensive system that allows you to maintain inventory, manage suppliers, and track supply chain activity in real-time, as well as streamline a variety of other corporate operations.

Deskera MRP allows you to closely monitor the manufacturing process. From the bill of materials to the production planning features, the solution helps you stay on top of your game and keep your company's competitive edge.

Deskera Books enables you to manage your accounts and finances more effectively. Maintain sound accounting practices by automating accounting operations such as billing, invoicing, and payment processing.

Deskera CRM is a strong solution that manages your sales and assists you in closing agreements quickly. It not only allows you to do critical duties such as lead generation via email, but it also provides you with a comprehensive view of your sales funnel.

Deskera People is a simple tool for taking control of your human resource management functions. The technology not only speeds up payroll processing but also allows you to manage all other activities such as overtime, benefits, bonuses, training programs, and much more. This is your chance to grow your business, increase earnings, and improve the efficiency of the entire production process.

Conclusion

Real-time inventory tracking brings significant benefits to manufacturing leaders, revolutionizing inventory management and driving operational efficiency. Real-time inventory tracking provides accurate and up-to-date visibility into inventory levels, locations, and movements.

This visibility empowers manufacturing leaders to make informed decisions regarding production planning, order fulfillment, and supply chain management. With real-time insights into inventory, leaders can prevent stockouts, reduce excess inventory, and ensure timely order fulfillment.

Real-time inventory tracking also contributes to improved supply chain management. By having real-time visibility into inventory levels and demand, manufacturing leaders can collaborate more effectively with suppliers and distributors.

This enables them to establish leaner and more efficient supply chains, reduce lead times, and minimize stockouts, ultimately improving overall supply chain performance.

Another key benefit of real-time inventory tracking is enhanced production planning and scheduling. Manufacturing leaders can align production schedules with real-time inventory data, ensuring that production is optimized to meet customer demand and reduce lead times. This helps avoid production bottlenecks and delays, improving operational efficiency and reducing costs.

By harnessing the power of real-time data, manufacturing leaders can optimize inventory levels, improve demand planning, enhance order accuracy, streamline supply chain management, and drive cost savings. Investing in real-time inventory tracking technology is a strategic decision that can yield significant competitive advantages in today's fast-paced and dynamic manufacturing landscape.

Key Takeaways

- Real-time inventory tracking provides accurate and up-to-date visibility into inventory levels, locations, and movements.

- It enables manufacturing leaders to make informed decisions regarding production planning, order fulfillment, and supply chain management.

- Real-time inventory tracking helps prevent stockouts and reduce excess inventory, leading to cost savings.

- It facilitates better demand planning and forecasting, ensuring optimal production schedules and reducing the risk of underproduction or overproduction.

- Real-time inventory tracking improves order accuracy and fulfillment, enhancing customer satisfaction.

- It enables manufacturing leaders to identify slow-moving or obsolete inventory, allowing for proactive measures to address these issues and optimize inventory turnover.

- Real-time inventory tracking enhances supply chain management by improving collaboration with suppliers and distributors.

- It helps establish leaner and more efficient supply chains, reducing lead times and minimizing stockouts.

- Real-time inventory tracking supports accurate financial reporting and cost management.

- It enables manufacturing leaders to track costs more effectively, make informed decisions regarding pricing and profitability, and generate accurate financial reports.

Related Articles