Leather manufacturing is a complex and time-consuming process and requires specialized skills, knowledge and experience. Outsourcing your leather manufacturing can be a great way to improve the quality of the leather products you produce and to increase efficiency in your production process.

This article covers the following:

- Benefits of Leather Manufacturing Outsourcing

- Challenges of Leather Manufacturing Outsourcing

- What to Look For in a Leather Manufacturing Outsourcing Partner

- The Cost of Leather Manufacturing Outsourcing

- What Is Involved in Leather Manufacturing Outsourcing?

- Quality Control in Leather Manufacturing Outsourcing

- Finding the Right Leather Manufacturing Outsourcing Company

- Tips for Choosing the Right Leather Manufacturing Outsourcing Partner

- What to Expect From Leather Manufacturing Outsourcing

- Environmental Considerations of Leather Manufacturing Outsourcing

Benefits of Leather Manufacturing Outsourcing

Leather manufacturing outsourcing has become increasingly popular in recent years, and for a good reason. From cost savings to quality assurance, the benefits of outsourcing for leather manufacturing are numerous.

Cost Savings

One of the main reasons for outsourcing leather manufacturing is the cost savings. By outsourcing production to a third party, you can reduce your overhead costs, such as wages and labor costs, as well as other operational costs.

Additionally, it’s often more cost-effective to outsource leather manufacturing than to invest in the necessary equipment and materials to produce the product in-house. Time Savings Time is money, and outsourcing leather manufacturing can save you both.

By outsourcing, you can free up valuable time that would otherwise be spent managing the production process in-house. This can be used to focus on other aspects of your business, such as marketing and design.

Additionally, outsourcing to a third party can often speed up the production process, as these companies often specialize in leather manufacturing and have the resources and expertise to deliver the product quickly and efficiently.

Quality Assurance

Outsourcing leather manufacturing can also help ensure quality control. By working with a third party, you can rest assured that the product you receive will meet your standards and specifications.

Additionally, third-party providers often have access to better technology and materials, allowing them to produce a higher-quality product. Expertise Another benefit of outsourcing leather manufacturing is the expertise of the third-party provider.

By outsourcing, you can tap into the knowledge and experience of the provider, which can be invaluable in the production process. The provider can also help advise you on the best materials and techniques to use, as well as provide insights into the latest developments in the industry.

Flexibility Outsourcing leather manufacturing can also provide you with more flexibility. By working with a third party, you can easily adjust production levels as needed, depending on your changing needs and requirements.

Additionally, third-party providers often have access to a larger range of materials and supplies, allowing you to customize the product to meet your exact specifications. Overall, the benefits of leather manufacturing outsourcing are numerous.

From cost savings to quality assurance, outsourcing can provide your business with the resources and expertise it needs to produce a high-quality product in a timely and cost-effective manner.

Challenges of Leather Manufacturing Outsourcing

Outsourcing is becoming more and more popular for leather manufacturing companies. It is a cost-effective way to increase production and reduce costs. However, it is important to remember that outsourcing leather manufacturing is not without its challenges.

First, it can be difficult to find a reliable and trustworthy outsourcing partner. Leather manufacturing is a complex process and requires specialized knowledge and expertise. Working with a partner who does not have the required skills and knowledge can lead to poor-quality products and lengthy delays.

It is important to research potential partners thoroughly to ensure they have the right qualifications and experience to do a good job. Second, there can be communication issues when outsourcing leather manufacturing.

When working with a partner that is located in a different country, there can be language and cultural barriers that can make it difficult to communicate effectively. Even if the partner speaks English, there may be misunderstandings when it comes to the technical aspects of the job.

This can lead to delays and errors in the production process. Third, there is the risk of intellectual property theft when outsourcing leather manufacturing. It is important to ensure that the partner you are working with has the proper security measures in place to protect your intellectual property.

Without these measures in place, the partner can easily copy and use your designs without your permission. Finally, there is the cost factor. Outsourcing leather manufacturing can be expensive, depending on the complexity of the job and the quality of the materials used.

It is important to do your research and compare prices before making a decision. Overall, outsourcing leather manufacturing can be a great way to increase production and reduce costs.

However, it is important to take the time to properly research potential partners and understand the challenges associated with outsourcing. By doing this, you can ensure that you are working with a reliable partner who can provide you with quality products on time and at an affordable price.

What to Look For in a Leather Manufacturing Outsourcing Partner?

When it comes to leather manufacturing, it’s important to have a reliable and experienced partner that you can trust to make your products to the highest quality standards. When outsourcing leather manufacturing, there are several factors you should consider to ensure you’re getting the best value for your money.

Quality:

Quality is key when it comes to leather manufacturing. Look for a partner that has a proven track record for producing high-quality products and can provide a comprehensive quality assurance program. Check for certifications from recognized organizations such as Leather Working Group.

Cost:

As with any business, the cost is an important factor when outsourcing leather manufacturing. Make sure to compare quotes from different partners to ensure you’re getting the best deal. Additionally, look for a partner that offers additional services such as design and prototyping that can help reduce overall costs.

Delivery:

When outsourcing, it’s important to have a reliable partner that can meet your delivery deadlines. Make sure to ask about their production and delivery times, as well as their policies for returns and refunds.

Experience:

Look for a partner that has experience working with leather and can offer a variety of options when it comes to materials, colors, and finishes. A partner with a wealth of experience can provide advice and guidance on the best materials and processes for your project.

Reputation:

Finally, make sure to research the reputation of any potential partners. Read customer reviews and ask former clients about their experiences. A reputable partner should have a good track record and be willing to provide references.

By considering these factors, you should be able to find a reliable and experienced partner for your leather manufacturing needs. With the right partner, you can be confident that your products will be of the highest quality and delivered on time.

The Cost of Leather Manufacturing Outsourcing

Leather manufacturing is a complex process that requires special materials, machinery, and techniques to produce the desired end product. When companies are looking to outsource their leather manufacturing needs, they must take into consideration the cost of the project.

Outsourcing leather manufacturing can be expensive but can also offer many advantages. Understanding the cost of leather manufacturing outsourcing can help businesses decide if this is the right choice for their particular needs.

The first factor to consider when it comes to the cost of leather manufacturing outsourcing is the type of leather being used. Different types of leather will require different processes, tools, and techniques to create the desired product.

This can greatly affect the cost of the project. For example, a project involving kangaroo leather will likely be more expensive than one using cowhide. Another factor to consider is the complexity of the project.

The more complex the project, the more expensive it will be. This is because more materials and resources are needed to complete the project. Additionally, complex projects may require specialized labor and machinery, which can add to the cost of the project.

The third factor to consider is the level of customization desired. Many leather manufacturing projects require a high level of customization, which can add to the cost of the project.

Customization can range from simple to complex, depending on the desired outcome. Finally, the cost of leather manufacturing outsourcing should also consider the cost of shipping the product.

Depending on the size and weight of the product, shipping costs can be a significant portion of the total cost of the project. Outsourcing leather manufacturing can be an excellent choice for businesses looking to reduce costs or increase production.

However, it is important to understand the cost of leather manufacturing outsourcing before making a decision. By considering the type of leather, the complexity of the project, the level of customization, and shipping costs, businesses can determine if outsourcing is the right choice for their needs.

What Is Involved in Leather Manufacturing Outsourcing?

Leather manufacturing outsourcing is when companies outsource the production of leather goods to an outside supplier. This process can involve anything from sourcing raw materials to designing, producing, and delivering finished products.

Outsourcing can be beneficial for a variety of reasons, including cost savings, access to specialized expertise, and increased efficiency. In this blog, we’ll take a closer look at what is involved in leather manufacturing outsourcing.

The first step in outsourcing leather goods is to find a reliable supplier. Companies need to make sure they are working with experienced, quality-focused manufacturers who have the capacity to meet their needs.

This includes researching potential suppliers, reviewing their portfolios, and asking for references. Once a manufacturer has been selected, the next step is to develop a product specification.

This includes details such as the type of leather, the color, and any other unique characteristics, such as a logo or embossing. Companies should also include all relevant safety and quality standards in their specification.

After the specification has been developed, the manufacturer will begin the production process. This includes sourcing the necessary raw materials, cutting the leather to the desired shape and size, stitching, and any other necessary steps.

Companies should also expect the supplier to provide regular updates on the progress of their order. Once the leather goods have been produced, the supplier will conduct a quality assurance check.

This includes inspecting the products for any defects and ensuring that they meet the specification. If any issues are identified, the supplier should address them before delivering the finished product.

Finally, the supplier will package and deliver the goods to the customer. Depending on the arrangement, this may involve the supplier taking care of all shipping and logistics, or the customer may need to provide their own transportation. In summary, leather manufacturing outsourcing involves finding a reliable supplier, developing a product specification, producing the goods, conducting quality assurance checks, and packaging and delivering the products.

Companies should carefully research potential suppliers and ensure that all safety and quality standards are met. By outsourcing their production, companies can benefit from cost savings, access to specialized expertise, and increased efficiency.

Quality Control in Leather Manufacturing Outsourcing

Quality control is an important part of leather manufacturing outsourcing. With the right processes in place, companies can ensure that their leather products meet the highest standards of quality and performance.

Poor quality control can lead to problems such as excessive waste, product defects, and customer complaints. The first step in quality control for leather manufacturing outsourcing is to establish the desired level of quality.

The quality guidelines should include specific requirements for the leather material, such as thickness, color, grain, and texture. The desired level of quality should also include specific requirements for the leather components, such as stitching, soles, and linings.

Once the desired level of quality is established, it is important to establish a quality assurance process. Quality assurance should involve regular inspections of the leather materials and components.

The quality assurance process should also include testing of the leather to ensure that it meets the required specifications. It is important to document all quality assurance results, so that any problems can be quickly identified.

In addition to establishing a quality assurance process, it is important to ensure that the leather manufacturing outsourcing provider has the necessary resources to meet the quality requirements.

This includes ensuring that the leather manufacturing outsourcing provider has the necessary machinery and personnel to produce the desired level of quality. It is also important to ensure that the leather manufacturing outsourcing provider has the necessary raw materials to produce the desired quality.

Finally, it is important to ensure that the leather manufacturing outsourcing provider has the necessary systems in place to track and monitor the quality of the leather. This includes systems to track the production process, as well as systems to monitor the quality of the leather.

This will ensure that any problems can be quickly identified and corrected. Quality control in leather manufacturing outsourcing is an important part of ensuring that the final products meet the desired level of quality.

Quality control should involve establishing the desired level of quality, establishing a quality assurance process, ensuring that the leather manufacturing outsourcing provider has the necessary resources to meet the desired level of quality, and ensuring that the leather manufacturing outsourcing provider has the necessary systems in place to track and monitor the quality of the leather.

By following these steps, companies can ensure that their leather products meet the highest standards of quality and performance.

Finding the Right Leather Manufacturing Outsourcing Company

Leather manufacturing is a highly specialized industry requiring a great deal of skill, knowledge, and experience. Finding the right leather manufacturing outsourcing company is a daunting task due to the sheer number of companies available and the wide range of services they offer. It is important to do research and take the time to find the right partner to ensure quality products and services. Here are some tips to help you find the right leather manufacturing outsourcing company:

Research the Company:

Before choosing a leather manufacturing outsourcing company, it is important to do some research to ensure that they have the necessary experience and expertise in the specific type of leather products you require. Check their credentials, past projects and customer reviews to ensure that you are working with a reliable and reputable company.

Know Your Requirements:

It is important to have a clear idea of the type of leather product you need, such as bags, wallets, jackets, etc., as well as the specific dimensions and other requirements. This will make it easier to narrow down your search for the right leather manufacturing outsourcing company.

Cost:

Cost is a major factor in any outsourcing decision. Make sure to compare quotes from multiple companies to find the best value for your money. It is also important to consider the quality of the products and services offered, as well as any additional costs that may be involved, such as shipping and handling.

Quality:

Quality should be the top priority when choosing a leather manufacturing outsourcing company. Make sure to ask for samples of their work and read customer reviews to ensure that the company produces high-quality products.

Delivery Time:

Ensure that the company can meet your delivery deadlines. Check their production capacity and ask for a delivery timeline to ensure that the company can meet your requirements.

By taking the time to do research and compare quotes from multiple leather manufacturing outsourcing companies, you can find the right partner for your project. With the right partner, you can be assured of quality products and services at a competitive price.

Tips for Choosing the Right Leather Manufacturing Outsourcing Partner

Choosing the right leather manufacturing partner is a critical decision for any business. If you’re looking to outsource your leather manufacturing, you want to make sure you’re partnering with a reliable, experienced and quality-driven partner that can deliver the results you need to grow your business. Here are some tips to help you choose the right leather manufacturing outsourcing partner:

Experience

Make sure you’re partnering with a company that has extensive experience in the leather manufacturing process. You want to make sure they know what they’re doing, and can provide you with the results you need. Ask for references or look for reviews to verify their experience and track record.

Quality

Quality is essential when it comes to leather manufacturing. Ask your potential partner about their quality control and quality assurance process. Make sure that they have a system in place to ensure that the leather is of the highest quality before it’s shipped.

Cost

Cost can be a major factor in your decision when it comes to outsourcing leather manufacturing. Make sure you’re getting the best value for your money. Research the market to get a good idea of what competitors are charging and compare the prices.

Location

Depending on the size of your order, you may want to consider outsourcing to a partner that’s located close to you. This will help you save on shipping costs and ensure your leather arrives on time.

Customization

Look for a partner that can offer customization options. This will allow you to create the exact product you want, and ensure that it meets your specific requirements.

Technology

The leather manufacturing process is highly dependent on technology. Make sure your potential partner is using the most up-to-date technology and tools to ensure the best results.

Communication

Communication is key when it comes to outsourcing. Make sure your potential partner is available for regular communication and that they understand your needs and expectations.

Choosing the right leather manufacturing partner is a critical decision that should not be taken lightly. Make sure you do your research and ask the right questions to ensure you make the right decision. With the right partner, you’ll be able to create high-quality leather products that your customers will love.

What to Expect From Leather Manufacturing Outsourcing?

Leather manufacturing is an essential part of making clothing, shoes, furniture, and many other products. It is also a complex process that requires a significant investment in time, money, and skill to produce quality leather goods.

For many companies, outsourcing leather manufacturing is a cost-effective way to increase production capacity and improve product quality. But what should you expect when outsourcing leather manufacturing?

First, you should expect experienced professionals with the necessary skills and expertise to produce quality leather goods. A reliable leather manufacturer should have a team of experienced workers with a comprehensive understanding of leather production techniques, from tanning and cutting to stitching and finishing.

They should also have access to the latest technology and machinery to ensure quality control throughout the entire production process. Second, you should expect a wide range of leather materials, colors, and textures.

A reliable leather manufacturer should have access to a variety of leather materials and a wide range of colors and textures. This ensures that you can find the perfect material for your product and that the finished product will have the look and feel you desire. Third, you should expect competitive prices.

A reliable leather manufacturer should be able to provide competitive prices that are in line with industry standards. This not only helps to keep costs low, but it also ensures that you are getting a quality product for an affordable price. Finally, you should expect quick turnaround times.

A quality leather manufacturer should be able to complete your order quickly and efficiently. This helps to ensure that your product will be delivered on time and that you won’t have to wait for weeks or months for your order to arrive.

By outsourcing leather manufacturing, you can save time, money, and stress while still receiving a high-quality product. When looking for a reliable leather manufacturer, make sure to consider the above factors and do your research to ensure that you are getting the best possible service and product.

Environmental Considerations of Leather Manufacturing Outsourcing

Leather manufacturing is a complex and specialized process that requires careful consideration of environmental factors. As the global demand for leather increases, so does the need for manufacturers to consider the environmental impacts of their production processes.

Outsourcing leather production to countries with lax environmental regulations can be a tempting option for companies looking to cut costs and maximize profits, but this can have disastrous consequences for the environment and the people who depend on it.

The leather manufacturing process is energy-intensive and relies on a range of hazardous chemicals, such as dyes and tanning agents, which can have serious impacts on air, water, and soil quality.

These pollutants can be released into the environment during the manufacturing process, and their effects can be long-lasting and far-reaching. In addition, many countries with lax environmental regulations may not have the necessary infrastructure to safely store and dispose of the hazardous chemicals and wastewater produced by the leather manufacturing process.

When companies outsource their leather production to countries with weaker environmental regulations, they are failing to take responsibility for the environmental impacts of their production processes.

This can have disastrous consequences for the environment and the people who depend on it. In addition, it can also lead to long-term economic costs for the companies involved.

One way for companies to reduce their environmental footprint when outsourcing leather production is to ensure that the facilities they are using are compliant with environmental regulations and that the chemicals used in the manufacturing process are safely stored and disposed of.

Companies should also consider investing in renewable energy sources and water conservation initiatives to reduce the energy and water use associated with the leather manufacturing process.

Finally, companies should consider using certified leather suppliers who have been audited and found to meet certain environmental standards. By doing so, companies can be sure that their leather production is taking place in an environmentally responsible manner and that the people and environment in the countries they are outsourcing to are being protected.

By taking the time to consider the environmental impacts of their production processes and making responsible sourcing decisions, companies can ensure that their leather production is both economically and environmentally sustainable.

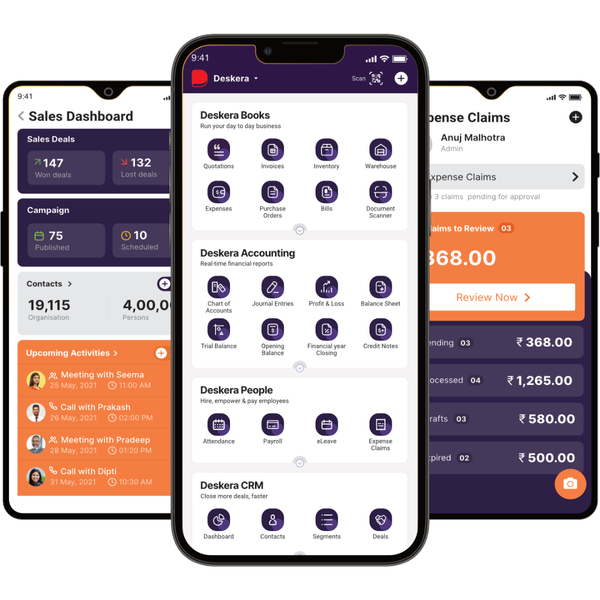

How Can Deskera Assist You?

As a manufacturer, you must keep track of your inventory stock. The condition of your inventory has a direct impact on production planning. It also has a direct impact on people and machinery use and capacity utilization.

Deskera MRP is the one tool that lets you do all of the above. With Deskera, you can:

- Control production schedules

- Compile a Bill of Materials

- Produce thorough reports

- Make your dashboard

Deskera ERP is a complete solution that allows you to manage suppliers and track supply chain activity in real-time. It also allows you to streamline a range of other company functions.

Deskera Books allows you to manage your accounts and finances better. It helps maintain good accounting standards by automating billing, invoicing, and payment processing tasks.

Deskera CRM is a powerful tool that organizes your sales and helps you close deals rapidly. It enables you to perform crucial tasks like lead generation via email and gives you a comprehensive view of your sales funnel.

Deskera People is a straightforward application for centralizing your human resource management activities. Not only does the technology expedite payroll processing, but it also helps you to handle all other operations such as overtime, benefits, bonuses, training programs, and much more.

Key Takeaways:

- The leather manufacturing industry is highly competitive, with many players vying for a share of the market.

- Another trend that is likely to shape the future of the leather industry is the growing demand for personalized and customized products.

- Emerging markets such as China, India, and Brazil are becoming major players in the leather industry.

- Some of the main environmental concerns associated with leather production include the use of hazardous chemicals, high water usage, air and water pollution, and deforestation.

- The future of the leather manufacturing industry is likely to be shaped by a range of factors, including changing consumer preferences, technological advancements, and environmental concerns.

Related Articles: