In chemical production and manufacturing, automation greatly enhances the efficiency and quality of a process. Automation allows for more efficient handling and control of chemical reactions to achieve desired product quality. It also has a significant impact on safety and environmental profile.

The growing demand for automated processes has necessitated the development of efficient technologies and systems. As technology develops, there are new opportunities for automation to be integrated into chemical production and manufacturing. staying ahead of the curve requires expertise in both automation technology and chemical processing.

In today's guide, we'll cover the top benefits of automation in chemical production and manufacturing along with related concepts. Before diving in, let's take a look at the table of content:

- Automation in Chemical Production and Manufacturing

- Top 10 Benefits of Automation in Chemical Production and Manufacturing

- Automation in Chemical Production Requires Attention to Detail

- Automation of Chemical Industries Can Boost Competitiveness

- Chemical Production & Manufacturing Automation Can Improve Worker Productivity

- The Future of Automation

- Wrapping Up

- How Deskera Can Assist You?

Let's get started!

Automation in Chemical Production and Manufacturing

Automation in chemical production and manufacturing is the use of robotic systems and software to control and monitor the manufacturing and production of chemicals.

It further reduces the need for manual labor and provides greater accuracy and efficiency in the production process. Automation can also help reduce waste, improve safety, and reduce environmental impacts.

Furthermore, automation in chemical production and manufacturing can include a wide range of activities, such as controlling machinery, monitoring chemical processes, and managing inventory.

Automation can also include the use of robotics to automate the manufacturing process, such as controlling the temperature, pressure, and flow rate of chemical reactions.

In addition, automation can also be used to monitor and control the quality of the final product, ensuring that it meets the specified standards.

Further, automation can also be used to monitor production process, such as tracking and tracing raw materials, tracking finished products, and managing inventory.

It can also be used to monitor and manage safety and environmental regulations, such as making sure that all chemicals are stored and handled properly. Automation can also be used to monitor and control the performance and safety of equipment and employees.

Finally, automation can be used to improve the efficiency of the production process, such as reducing energy consumption, decreasing production costs, and increasing production throughput.

Automation can also help to reduce the risk of human error and improve the quality of the product. It can be used to control the production process, monitor quality control, and manage inventory. Furthermore, automation can also be used to optimize the production process and improve the overall efficiency of the production process.

Top 10 Benefits of Automation in Chemical Production and Manufacturing

Following, we've discussed crucial top 10 benefits of automation in chemical production and manufacturing. Let's learn:

1. Enhanced Safety

Automation can be used to increase safety in chemical production and manufacturing by reducing human error and improving the accuracy of procedures. It can also help to monitor process conditions more accurately and provide feedback to operators in real time.

Furthermore, automation can be used to detect dangerous conditions before they become hazardous and to alert operators to take corrective action. Automation can also help reduce the number of manual tasks, which can help prevent accidents due to operator fatigue.

Finally, automation can be used to provide a more consistent quality of product, which helps to reduce the risk of unsafe products reaching the market.

2. Improved Efficiency

Automation is the use of technology to control and monitor production processes, reducing the need for human intervention. Furthermore, it can help increase efficiency and productivity in chemical production and manufacturing processes in a variety of ways.

First, automation can reduce errors and increase accuracy. Automated systems can help ensure that the right chemicals and materials are used in the right amounts, and that the correct processes are followed. This can reduce waste and increase the quality of the finished product.

Second, automated systems can help speed up production processes. Automation can be used to streamline production and cut down on time-consuming manual tasks. This can lead to faster production cycles and higher throughput.

Third, automation can reduce labor costs. Automated systems can reduce the amount of labor needed to complete a task, allowing companies to reduce labor costs while increasing productivity. Further, automation can also help reduce the cost of training and onboarding new workers.

Finally, automation can help improve safety in the workplace. Also, automated systems can help reduce the risk of accidents, as well as help enforce safety procedures and protocols. Automated systems can also help reduce the risk of exposure to hazardous chemicals and materials.

Overall, automation can help increase efficiency and productivity in chemical production and manufacturing processes. Automation can help improve process accuracy, reduce material waste and cost, and provide visibility into processes.

Additionally, it can also help ensure compliance with safety and environmental regulations, while simultaneously freeing up resources to focus on higher-value tasks. Automation can also open up opportunities to explore new production techniques, optimize processes, and increase output.

3. Cost Savings

Automation can help to reduce costs in chemical production and manufacturing in several ways. Moreover, automation processes can help to reduce labor costs, increase productivity, reduce waste, improve the accuracy and consistency of production, and reduce the need for manual oversight.

Automation can also reduce energy costs, both in terms of the energy used to power the machines and in terms of the energy used to produce the chemicals themselves. it further helps to reduce the cost of raw materials by streamlining the production process, reducing waste, and improving the accuracy of the production process.

Finally, automation can help to reduce safety costs by improving safety protocols and reducing the risk of injury or illness. Automation can also help to reduce the costs associated with product quality control and assurance, by ensuring that products are consistently produced to the highest standard.

4. Reduce Waste

Automation is one of the most effective ways to reduce waste in chemical production and manufacturing. Automation reduces human error and ensures that processes are completed accurately and efficiently. It also cuts down on labor costs, as fewer humans are needed to complete the same work.

Further, automated systems are also able to more accurately measure the amounts of materials used for each production process, which helps to reduce waste. It also provides real-time data on production processes, which can be used to make adjustments to reduce waste.

Finally, automation can be used to track and monitor the waste materials generated during production processes, allowing for more effective waste management.

5. Increased Scalability

Automation has been an integral part of chemical production and manufacturing for many years. Automation is the use of machines, computers, and other technology to automate processes and operations. Also, automation allows for more efficient production and manufacturing, as well as increased scalability.

Moreover, it can be used to increase scalability in chemical production and manufacturing by speeding up the production process, reducing costs, and increasing production accuracy.

In addition, it can also help to improve safety by eliminating human error and increasing consistency. It can also increase scalability by allowing multiple production lines to be run simultaneously, increasing production throughput and reducing the amount of time needed to produce a given amount of product.

Automation can also be used to increase scalability in chemical production and manufacturing by providing improved process control and monitoring. Automated systems can be used to track production variables such as temperature, pressure, and flow, and can be used to provide real-time feedback on production efficiency and quality.

Moreover, automation can also be used to provide predictive analysis and process optimization, allowing operations to be adjusted in order to maximize efficiency and scalability. Additionally, automation can be used to provide data collection and analysis, allowing for improved decision-making and cost savings.

6. Minimizing Unscheduled Downtime

Automation in chemical production and manufacturing can help reduce unscheduled downtime by improving efficiency, accuracy, and safety. Here are some ways automation can achieve this goal:

Predictive Maintenance: Automation can enable real-time monitoring of equipment and systems to detect signs of wear, tear, or malfunction before they lead to unscheduled downtime. This predictive maintenance approach allows for timely repairs and maintenance to prevent downtime.

Process Control: Automation can provide precise control of chemical processes, reducing the chance of errors and variations that can cause downtime. Automated control systems can continuously adjust process variables such as temperature, pressure, and flow rate, to ensure that the production process stays within the desired parameters.

Remote Monitoring: Automation allows operators to remotely monitor the production process, reducing the need for manual inspections, and providing early warning of potential problems that could cause unscheduled downtime.

Data Analytics: Automation can collect and analyze production data, identifying patterns and trends that can predict potential failures and trigger maintenance before downtime occurs. This data-driven approach can also help identify opportunities for process optimization and efficiency improvements.

Safety: Automation can reduce the risk of human error, which can cause equipment damage and unscheduled downtime. By automating hazardous tasks, such as handling chemicals, it can minimize the risk of accidents and downtime caused by safety incidents.

In summary, automation can help reduce unscheduled downtime in chemical production and manufacturing by enabling predictive maintenance, precise process control, remote monitoring, data analytics, and improved safety.

7. Product Lifecycle Management (PLM)

Automation in chemical production and manufacturing can improve product lifecycle management (PLM) by streamlining and integrating the various stages of the product lifecycle, from research and development to production, and ultimately to end-of-life management. Here are some ways automation can help with PLM:

Product Development: Automation can accelerate the product development process by allowing for rapid testing and prototyping. For example, automated lab equipment can quickly analyze and test new formulations, reducing the time and cost of product development.

Production Planning: Automation can help plan and optimize production by providing real-time information on production processes and materials availability. This can ensure that production schedules are efficient and responsive to changing demand.

Quality Control: Automation can ensure consistent product quality by monitoring critical quality parameters in real-time. This can help detect and correct quality issues before they result in a product recall or customer complaint.

End-of-Life Management: Automation can help manage the end-of-life phase of products by facilitating the reuse, recycling, or disposal of materials in a safe and sustainable manner. This can help reduce waste and environmental impact and improve the company's sustainability profile.

Regulatory Compliance: Automation can ensure compliance with regulatory requirements, such as product labeling and safety standards. This can help avoid costly penalties and reputational damage due to non-compliance. Learn about this in the following section.

8. Regulatory Compliance

Automation in chemical production and manufacturing can help improve regulatory compliance by reducing the risk of non-compliance and enabling more efficient and effective compliance management. Here are some ways automation can help with regulatory compliance:

Real-Time Monitoring: Automation can enable real-time monitoring of production processes, which can help detect and correct compliance issues before they result in regulatory violations. For example, automated sensors can monitor process variables such as temperature, pressure, and chemical concentrations, and alert operators to deviations from permitted limits.

Electronic Record-Keeping: Automation can enable electronic record-keeping, which can help ensure accurate and complete documentation of compliance-related activities. This can help reduce the risk of errors, omissions, or tampering, and facilitate the retrieval and sharing of information during regulatory inspections.

Compliance Reporting: Automation can help generate compliance reports and documents, which can help streamline the reporting process and ensure accuracy and consistency. For example, automated systems can generate safety data sheets, product labels, and environmental reports based on standardized templates and data inputs.

Training and Certification: Automation can help ensure that employees are properly trained and certified for compliance-related tasks. For example, automated training modules can provide employees with interactive, self-paced training on topics such as safety procedures, hazardous materials handling, and regulatory requirements.

Auditing and Inspection: Automation can help prepare for and manage regulatory audits and inspections. For example, automated systems can help track compliance-related tasks and deadlines, provide access to electronic records and documents, and generate reports and checklists to help ensure that all regulatory requirements are met.

9. Training and Security

Automation in chemical production and manufacturing can help accelerate training and improve safety by providing interactive and immersive training experiences, reducing the need for manual handling of hazardous materials, and enabling real-time monitoring of safety-critical processes. Here are some ways automation can help with training and safety:

Virtual and Augmented Reality Training: Automation can provide virtual and augmented reality training simulations that can provide hands-on training in a safe and controlled environment. This can help employees learn how to operate complex equipment and manage hazardous materials, without the risk of injury or property damage.

Robotics and Automated Handling: Automation can reduce the need for manual handling of hazardous materials by using robotics and automated handling systems. This can help reduce the risk of accidents and injuries caused by exposure to hazardous chemicals or physical strain.

Real-Time Monitoring: Automation can enable real-time monitoring of safety-critical processes, which can help detect and prevent safety incidents before they occur. For example, automated sensors can monitor process variables such as temperature, pressure, and chemical concentrations, and alert operators to deviations from safe levels.

Safety Checks and Interlocks: Automation can incorporate safety checks and interlocks into equipment and processes, which can prevent unsafe conditions from occurring. For example, automated interlocks can prevent equipment from starting unless all safety systems are functioning properly.

Predictive Maintenance: Automation can enable predictive maintenance of equipment, which can help prevent safety incidents caused by equipment failures. By monitoring equipment in real-time and detecting early signs of wear and tear, automation can schedule maintenance proactively, reducing the risk of equipment failure.

10. Communication

Automation in chemical production and manufacturing can help improve communication by enabling real-time data exchange, facilitating collaboration, and providing centralized and standardized information.

Following, we've discussed some ways automation can help with communication:

Real-Time Data Exchange: Automation can enable real-time data exchange between different systems and equipment, which can help ensure that everyone has access to the same up-to-date information. For example, automated systems can share data on production processes, quality control, and inventory levels, which can help ensure that everyone is working with the same information and can make informed decisions.

Collaboration Tools: Automation can provide collaboration tools, such as shared workspaces and messaging systems, which can help employees work together more effectively. For example, automated systems can provide a shared platform for teams to collaborate on projects, share files and data, and communicate in real-time.

Centralized Information: Automation can help centralize information, such as standard operating procedures, compliance requirements, and safety guidelines, which can help ensure that everyone is working with the same information. This can help reduce errors, omissions, and misunderstandings, and facilitate more efficient and effective decision-making.

Standardized Formats: Automation can help standardize information formats, such as data structures and reporting templates, which can help ensure consistency and accuracy across different systems and departments. This can help reduce confusion and errors caused by variations in data formats, and facilitate more efficient and effective communication.

Dashboards and Alerts: Automation can provide dashboards and alerts, which can help employees monitor and respond to critical events in real-time. For example, automated systems can generate alerts when a production process deviates from established parameters, or when a compliance deadline is approaching.

Automation in Chemical Production Requires Attention to Detail

Automation in chemical industries is becoming a more and more attractive and common practice. But those who are passionate about it should proceed slowly and think about what they want to achieve with their efforts most.

A business leader could want to automate a task that requires a lot of effort, is prone to error, or both. Yet, automation of chemical manufacturing may require a lot more work. Over several weeks or months at a time, for instance, technology might be able to manage the majority of a facility's ongoing operations.

Setting a budget is a vital stage in the automation of chemical facilities. It makes sense that plant managers are reluctant to invest a sizable sum of money in technology before realizing a profit. But they should also take into account the estimated costs of the improvements that are most likely to have the intended effect.

Time must be spent on fostering staff enthusiasm for automation. Many of them could be concerned about being replaced in the workforce by cutting-edge technologies. Yet, managers may allay fears and help workers understand that automation will benefit them and potentially even make their employment more enjoyable.

When business leaders take crucial factors like these into account, their efforts to automate chemical facilities are more likely to be successful. Yet, people should be aware that practically all automation projects encounter some difficulties. Everyone's motivation is kept up when they are dedicated to and concentrated on the long-term objectives in spite of these short-term difficulties.

Automation of Chemical Industries Can Boost Competitiveness

Leaders in the chemical industry must assess the most effective development strategies in order to stay competitive. Automating the production of chemicals is one way to achieve this, particularly because it can help plant managers deal with persistent issues.

That was the situation at a chemical industry in Northeastern Ohio. At first, the company mostly catered to customers in the Midwest. Yet, it grew over time and today employs 200 people around the country.

Notwithstanding this achievement, the management of the company encountered challenges because of declining profit margins and a shrinking labor force. Also, they observed a rise in competitors on a global scale and realized that changes were necessary if the company was to survive.

In response, they worked with a company that provides automation as a service, which allowed them to access collaborative robots through a lease arrangement. Because there was no upfront cost, many CEOs liked how this arrangement reduced risk and provided more flexibility.

Moreover, experimentation is made possible by testing out the technology before automating chemical facilities on a larger scale. That aspect appealed to the executives at the Ohio chemical industry who weren't yet ready to make large bets on automation.

The purpose of the cobots was to assist humans in moving different-sized containers off assembly lines and onto carts and cartons. It seems sense that carrying out that task without the assistance of robots may quickly become too exhausting given that some of them weigh as much as 40-pound containers.

The objective is to supplement human labor rather than replace it. Employees may be more likely to stay with a company for a longer period of time and even urge others to work there if they believe their jobs are more pleasurable and less physically taxing.

If this were the case, the chemical factory would learn that it was simpler to maintain access to a skilled and motivated personnel, boosting its ability to compete in the market.

Chemical Production & Manufacturing Automation Can Improve Worker Productivity

In chemical production and manufacturing, automation can be an effective way to get rid of bottlenecks and other annoyances that periodically make employees feel worn out from their work. As a result, their total performance ought to improve, and employment retention rates ought to rise.

Alarms typically sound at chemical plants to alert staff when statistics pertaining to a piece of equipment or process have strayed outside of desired parameters. Yet, not all of these signals necessitate prompt human attention. Automated machine monitoring can be used in chemical industries to improve the performance of crucial equipment while freeing up staff to work on more rewarding projects.

Several employees at two of Koch Fertilizer's urea ammonium nitrate factories use process automation to collect data and use the results. Afterwards, they can modify the specifics for the best outcomes. These board operators may now make fewer manual modifications thanks to automation.

Earlier, some people handled hundreds of alarms each day using a keyboard-based method. But, if they choose an automated technique, they might discover that they are only required to respond to a few warnings every day. They also assert that automation frees up more time for analysis and strategy than was previously possible, allowing them to think more critically about corporate operations.

Automation in chemical plants can also reduce the likelihood of mistakes. Koch staff used automation to implement state-based control. This improves the steps required to start or stop electricity and get it into a stable operational state. Because fewer manual actions are needed that could go wrong with even a tiny error, processes are safer and run more effectively as a result.

The Future of Automation

The sector's and each facility's upbeat predictions indicate a promising future for the bulk chemicals industry. But there will be obstacles on your path. Chemical manufacturers will under more greatly pressure than ever to develop a sustainable differentiator in a heavily commoditized sector as global competition heats up.

A price-based competitive approach can only go so far given the already slim margins and the erratic cost of electricity and raw commodities.

Automation has long been important in process industrial sectors like bulk chemicals. Nonetheless, a revolution in automation is about to begin. Similar differences exist between landing on the Moon and sending a manned expedition to Mars. Given that your portable smartphone has a considerably more powerful computer than the Apollo Guidance System, this analogy is appropriate.

Today's software and machinery for chemical production go beyond merely regulating process variables like flow rate and temperature. More data than ever before is gathered from more process components thanks to modern technology. This data is transformed into useful knowledge by advanced analytics. Employees have access to it through mobile devices, giving them the knowledge, they need to make choices more quickly and effectively, optimize processes, and reduce expenses.

We believe that the future of chemical manufacturing won't belong to the corporation that can drop its prices below those of the rivals. The manufacturer who recognizes the promise of automation and uses it to update ingrained business practices already has it.

Wrapping Up

Automation in chemical production and manufacturing can provide significant benefits, including increased efficiency, improved product quality, reduced costs, enhanced safety, and improved regulations compliance.

The use of automation in chemical production and manufacturing allows for faster, more accurate, and more reliable operations, reducing the risk of human error and enhancing overall process control. Automation can also enable real-time monitoring of critical process variables, such as temperature, pressure, and chemical concentrations, which can improve product quality and reduce the risk of defects or batch failures.

By reducing the need for manual intervention, automation can also help reduce costs associated with labor, energy, and waste. Automation can also help companies meet regulatory requirements by providing real-time data and enabling compliance tracking and reporting.

Perhaps most importantly, automation can enhance safety in chemical production and manufacturing by reducing the risk of accidents and exposure to hazardous materials.

Furthermore, automated systems can provide interlocks and safety checks, monitor critical safety variables, and provide real-time alerts to operators in case of emergencies.

Overall, the benefits of automation in chemical production and manufacturing are numerous, and can help companies improve efficiency, reduce costs, enhance safety, and improve compliance. As technology continues to advance, the use of automation is likely to become even more prevalent in the chemical industry, driving increased innovation, competitiveness, and growth.

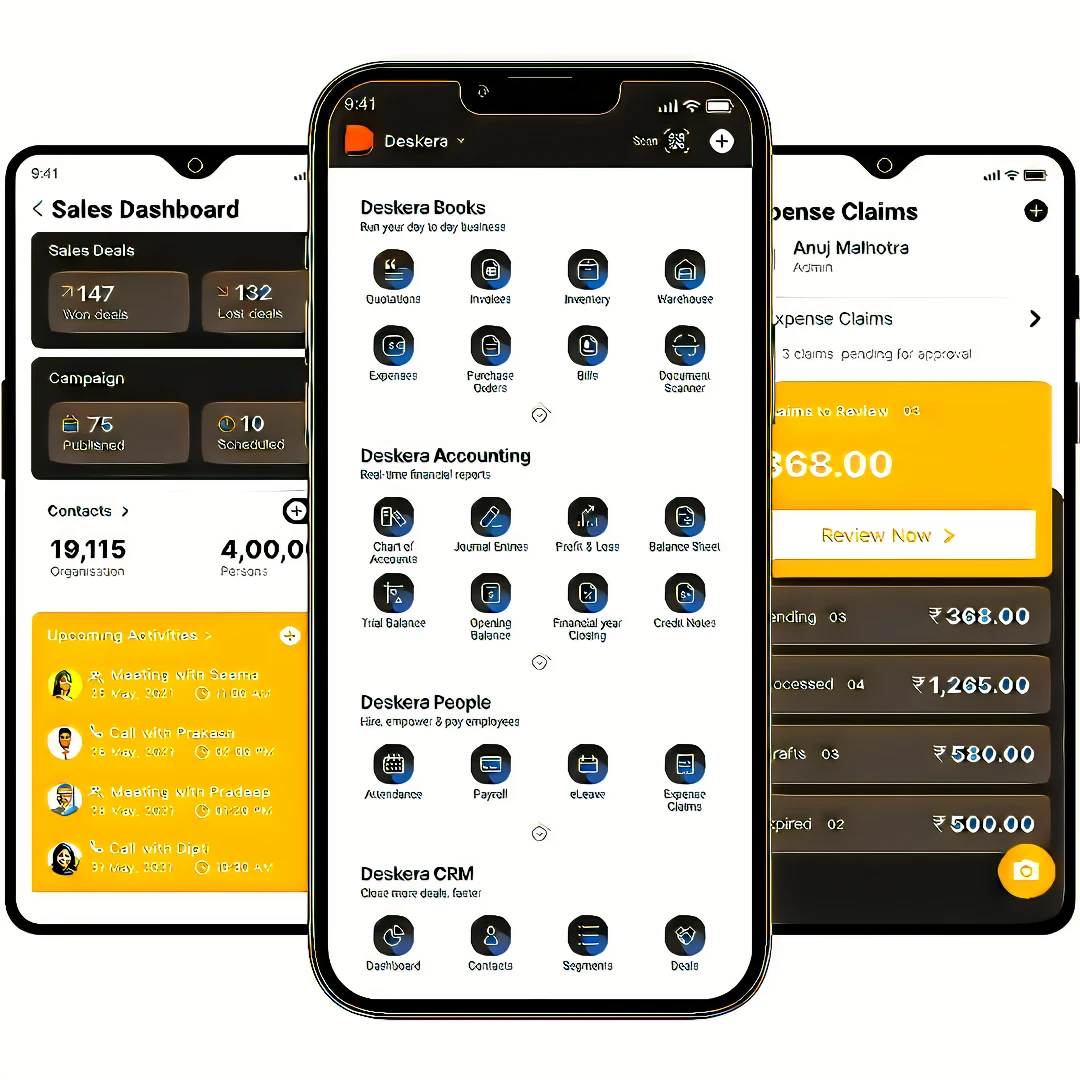

How Deskera Can Assist You?

Deskera's integrated financial planning tools allow investors to better plan their investments and track their progress. It can help investors make decisions faster and more accurately.

Deskera Books enables you to manage your accounts and finances more effectively. Maintain sound accounting practices by automating accounting operations such as billing, invoicing, and payment processing.

Deskera CRM is a strong solution that manages your sales and assists you in closing agreements quickly. It not only allows you to do critical duties such as lead generation via email, but it also provides you with a comprehensive view of your sales funnel.

Deskera People is a simple tool for taking control of your human resource management functions. The technology not only speeds up payroll processing but also allows you to manage all other activities such as overtime, benefits, bonuses, training programs, and much more. This is your chance to grow your business, increase earnings, and improve the efficiency of the entire production process.

Final Takeaways

We've arrived at the last section of this guide. Let's have a look at some of the most important points to remember:

- Automation in chemical production and manufacturing is the use of robotic systems and software to control and monitor the manufacturing and production of chemicals. It further reduces the need for manual labor and provides greater accuracy and efficiency in the production process.

- It can be used to control the production process, monitor quality control, and manage inventory. Automation can also be used to optimize the production process and improve the overall efficiency of the production process.Automation can reduce errors and increase accuracy. Automated systems can help ensure that the right chemicals and materials are used in the right amounts, and that the correct processes are followed. This can reduce waste and increase the quality of the finished product.

- Predictive Maintenance: Automation can enable real-time monitoring of equipment and systems to detect signs of wear, tear, or malfunction before they lead to unscheduled downtime. This predictive maintenance approach allows for timely repairs and maintenance to prevent downtime.

- Data Analytics: Automation can collect and analyze production data, identifying patterns and trends that can predict potential failures and trigger maintenance before downtime occurs. This data-driven approach can also help identify opportunities for process optimization and efficiency improvements.

- Product Development: Automation can accelerate the product development process by allowing for rapid testing and prototyping. For example, automated lab equipment can quickly analyze and test new formulations, reducing the time and cost of product development.

- Real-Time Monitoring: Automation can enable real-time monitoring of production processes, which can help detect and correct compliance issues before they result in regulatory violations. For example, automated sensors can monitor process variables such as temperature, pressure, and chemical concentrations, and alert operators to deviations from permitted limits.

Related Articles