In the bustling world of manufacturing, where precision and efficiency reign supreme, the art of production scheduling plays a critical role in orchestrating the symphony of processes that lead to successful product outcomes.

However, for decades, manufacturers have grappled with the complexities of this intricate dance, facing challenges like manual planning, uncertain variables, and the ever-elusive quest for optimal resource allocation.

But just as the industrial landscape witnessed groundbreaking revolutions in the past, a new era has emerged – one where machines think, learn, and optimize like never before. Welcome to the age of Artificial Intelligence (AI) and its remarkable transformation of production scheduling in manufacturing.

A survey conducted by McKinsey found that 69% of manufacturing companies have already implemented AI in at least one part of their production process, with production scheduling being a key focus area. In another study by Deloitte, 76% of manufacturers reported that AI technologies have significantly improved their production scheduling accuracy and reduced production downtime.

As AI continues to evolve, it brings with it a plethora of possibilities, offering manufacturers a ticket to unprecedented levels of efficiency, productivity, and adaptability.

So, fasten your seatbelts as we embark on a journey through the realm of AI, exploring how this disruptive technology is revolutionizing production scheduling in the manufacturing landscape, reshaping the very foundations of an industry that has always embraced progress.

- Overview of Production Scheduling in Manufacturing

- Importance of Efficient Production Scheduling for Manufacturing Industries

- Transition to AI-Driven Solutions for Production Scheduling

- Traditional Production Scheduling Challenges

- The Emergence of AI in Manufacturing

- How AI Improves Production Scheduling

- AI-Powered Tools for Production Scheduling

- Benefits of AI-Driven Production Scheduling

- Overcoming Challenges and Considerations

- Future Prospects and Trends

- Ethical Implications of AI in Production Scheduling

- Emphasizing The Transformative Potential For Manufacturing Industries

- Widespread Adoption Of AI-Driven Solutions For A Competitive Edge

- Conclusion

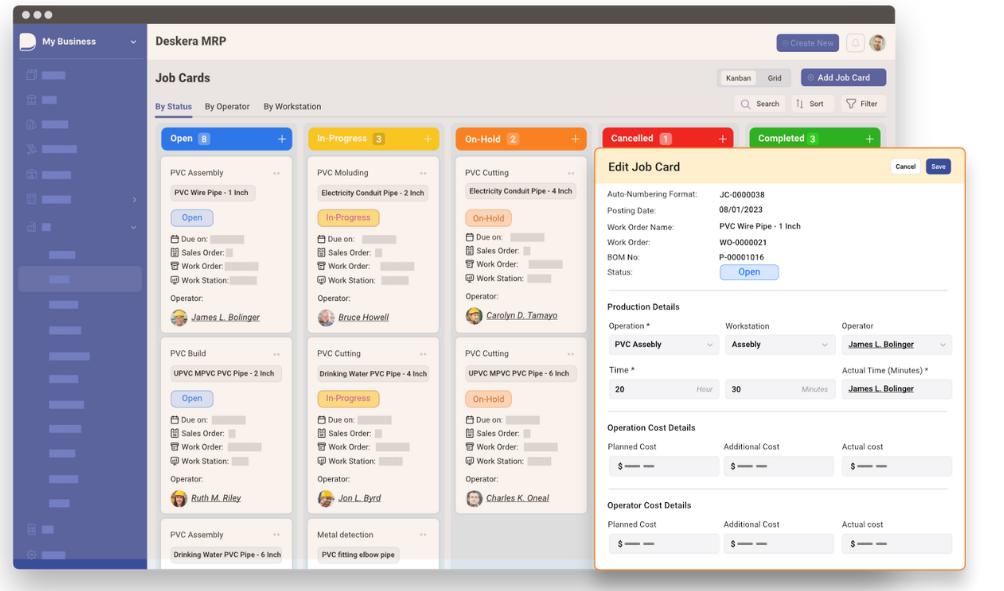

- How can Deskera Help You?

- Key Takeaways

- Related Articles

Overview of Production Scheduling In Manufacturing

Production scheduling in manufacturing is a crucial process that involves planning and organizing the various tasks, resources, and timelines required to produce goods efficiently and meet customer demands. It serves as the backbone of manufacturing operations, ensuring that the right products are manufactured in the right quantities, at the right time, and using the right resources.

The primary goal of production scheduling is to optimize production processes, minimize production costs, reduce lead times, and maximize overall productivity.

Key Components of Production Scheduling:

Resource Allocation: Determining which resources, such as raw materials, equipment, and labor, will be utilized for specific production tasks and how they will be allocated throughout the production process.

Time Management: Establishing timelines and deadlines for each production task, ensuring that production activities are completed in a coordinated and timely manner.

Sequencing: Arranging the order in which production tasks are executed to ensure smooth workflow, minimal idle time, and efficient resource utilization.

Capacity Planning: Assessing the production capacity of the manufacturing facility to match it with demand and avoid overloading or underutilization of resources.

Demand Forecasting: Accurately predicting future demand for products to plan production schedules that meet customer requirements without excessive inventory buildup.

Optimization: Utilizing mathematical models and algorithms to find the most efficient and cost-effective production schedules, considering factors like production volume, setup times, and resource constraints.

Challenges in Production Scheduling:

Production scheduling in manufacturing is a complex task with several challenges that manufacturers face:

Dynamic Environment: Manufacturing processes are subject to frequent changes due to machine breakdowns, material shortages, or unexpected demand fluctuations, making it difficult to maintain an optimal schedule.

Resource Constraints: Limited availability of resources like labor, machinery, and materials can create bottlenecks and impact the production schedule.

Interdependence of Tasks: Many production tasks are interconnected, and delays in one task can affect the entire production schedule.

Data Complexity: Gathering and analyzing relevant data, including production data, inventory levels, and market demands, can be challenging, especially for large-scale manufacturing operations.

Competing Objectives: Production scheduling often involves balancing conflicting objectives, such as minimizing production costs while meeting tight delivery deadlines.

The Role of Technology in Production Scheduling:

Traditional methods of production scheduling relied heavily on manual planning and experience-based decision-making. However, with the advent of technology and the rise of AI, manufacturers have increasingly turned to automated and data-driven solutions to overcome scheduling challenges.

Advanced Planning and Scheduling (APS) systems, powered by AI and machine learning algorithms, are becoming popular for optimizing production schedules, considering various constraints and real-time data updates.

Overall, efficient production scheduling is vital for manufacturing industries to remain competitive, meet customer demands, and maximize operational efficiency. As AI continues to advance, it promises to revolutionize production scheduling, enabling manufacturers to tackle complexity, uncertainty, and variability with unprecedented levels of accuracy and adaptability.

Importance of Efficient Production Scheduling For Manufacturing Industries

Efficient production scheduling is a cornerstone of success for manufacturing industries, offering a multitude of benefits that directly impact their competitiveness, profitability, and customer satisfaction. The significance of efficient production scheduling can be understood through the following key points:

Optimized Resource Utilization: Effective production scheduling ensures that all resources, including raw materials, equipment, and labor, are utilized optimally. This prevents overloading or underutilization of resources, leading to reduced production costs and increased overall efficiency.

Minimized Lead Times: By streamlining production processes and eliminating bottlenecks, efficient scheduling reduces lead times – the time taken from order placement to product delivery. Shorter lead times enhance customer satisfaction, as manufacturers can respond quickly to changing market demands and fulfill orders promptly.

Reduced Inventory Costs: Accurate production scheduling aligns production with demand forecasts, preventing unnecessary stockpiling of finished goods. This reduces inventory holding costs and the risk of obsolete inventory, freeing up capital for other investments.

Improved On-Time Delivery: With efficient scheduling, manufacturers can meet delivery deadlines consistently. This fosters a reputation for reliability and helps build long-term relationships with customers, leading to repeat business and customer loyalty.

Enhanced Flexibility and Adaptability: In dynamic manufacturing environments, changes are inevitable. Efficient production scheduling allows manufacturers to adapt to unexpected disruptions, such as machine breakdowns or material shortages, minimizing the impact on production schedules.

Better Planning for Maintenance and Downtime: By having a well-structured production schedule, manufacturers can plan routine maintenance and downtime in advance, minimizing production interruptions and maximizing equipment availability.

Cost Reduction and Increased Profitability: Optimized production scheduling reduces production inefficiencies, cuts down on overtime costs, and minimizes wastage. This, in turn, leads to improved profitability and a competitive edge in the market.

Empowerment of Workforce: A clear and well-defined production schedule provides the workforce with a sense of direction and purpose. It allows employees to focus on specific tasks, enhances collaboration, and fosters a more efficient working environment.

Effective Resource Planning: Efficient production scheduling aids in long-term resource planning and investment decisions. Manufacturers can forecast future resource requirements based on historical data and anticipated demand, leading to better strategic decision-making.

Sustainable Manufacturing Practices: By reducing waste and optimizing energy consumption, efficient production scheduling contributes to sustainable manufacturing practices, minimizing the environmental impact of operations.

In summary, efficient production scheduling is a vital component of successful manufacturing industries. It enables companies to operate with agility, precision, and cost-effectiveness, meeting customer demands while optimizing the use of resources. As AI-driven solutions continue to advance, the potential for further optimizing production scheduling becomes even more promising, paving the way for a more productive and sustainable manufacturing future.

Transition to AI-Driven Solutions for Production Scheduling

The transition to AI-driven solutions for production scheduling marks a significant paradigm shift in the manufacturing landscape. As traditional methods face limitations in handling complexities, uncertainties, and real-time data, the integration of Artificial Intelligence (AI) brings about transformative changes and opens up new possibilities for optimizing production processes.

The following factors drive the transition to AI-driven solutions:

Data-Driven Decision Making: AI-enabled production scheduling leverages vast amounts of historical and real-time data from various sources, including production data, inventory levels, machine performance, and customer demands. This data-driven approach enables more accurate and informed decision-making, leading to better scheduling outcomes.

Complexity and Variability Management: Manufacturing processes often involve intricate networks of tasks, dependencies, and constraints. AI algorithms can analyze these complexities to identify the most efficient and feasible schedules, considering multiple variables and interdependencies simultaneously.

Real-Time Adaptability: In dynamic manufacturing environments, unexpected events like machine breakdowns or supply chain disruptions can significantly impact production schedules. AI-driven solutions can swiftly adapt and re-optimize schedules in real-time to minimize downtime and maintain operational efficiency.

Optimization Algorithms: AI-powered optimization algorithms can handle large-scale problems with numerous constraints and objectives. These algorithms can find near-optimal solutions quickly, ensuring that production schedules are efficient and cost-effective.

Enhanced Predictive Capabilities: AI can predict demand patterns, equipment failures, and supply chain fluctuations more accurately than traditional methods. This foresight allows manufacturers to proactively adjust production schedules to meet anticipated demands and avoid potential disruptions.

Efficient Resource Allocation: AI algorithms can allocate resources intelligently, considering factors such as equipment availability, skill levels of workers, and material availability. This ensures optimal resource utilization, reducing costs and increasing productivity.

Integration with IoT and Automation: AI-driven production scheduling can be seamlessly integrated with the Internet of Things (IoT) and automation technologies. This integration enables real-time data exchange and feedback between machines and scheduling systems, enhancing production efficiency and agility.

Scalability and Customization: AI-driven production scheduling solutions can cater to the specific needs of various manufacturing industries and adapt to different production environments. These solutions are scalable, making them suitable for both small and large-scale manufacturing operations.

Continuous Learning and Improvement: AI systems can continuously learn from past performance, allowing them to improve their scheduling capabilities over time. As more data is collected and analyzed, the AI models become more refined and accurate, leading to better scheduling outcomes.

Competitive Advantage: Manufacturers that adopt AI-driven production scheduling gain a competitive edge by achieving higher levels of productivity, reduced costs, and improved customer satisfaction. Staying ahead in today's fast-paced market requires embracing AI technology to optimize operations continually.

In conclusion, the transition to AI-driven solutions for production scheduling is a game-changer for manufacturing industries. By harnessing the power of AI, manufacturers can tackle the challenges of complex production environments, optimize resources, and respond dynamically to changing demands, fostering a more agile, efficient, and competitive manufacturing landscape.

Traditional Production Scheduling Challenges

Navigating the intricate world of manufacturing production has long been a challenging endeavor, as manufacturers grapple with a myriad of complexities and uncertainties. Traditional production scheduling, the art of orchestrating a harmonious production process, has faced its share of obstacles, relying on manual planning and experience-based decision-making.

However, as the manufacturing landscape evolves and demands become more dynamic, these age-old challenges have become even more pronounced, underscoring the need for innovative solutions to optimize production processes.

In this section, we delve into the traditional production scheduling challenges that have persisted over time, shedding light on the limitations and inefficiencies that have driven the quest for transformative advancements in manufacturing scheduling practices.

A. Manual planning and its limitations

In the realm of manufacturing, manual planning has long been the bedrock of production scheduling. Historically, production managers and planners meticulously crafted schedules based on their experience, intuition, and expertise. While this approach served its purpose in simpler times, the modern manufacturing landscape presents a host of complexities that have exposed the limitations of manual planning.

Time-Consuming and Prone to Errors: Manual production scheduling is a labor-intensive task that involves juggling numerous production factors, resource constraints, and demand fluctuations. As schedules grow in complexity, the risk of human errors increases, leading to costly production delays and inefficiencies.

Difficulty in Handling Large Data Volumes: With the advent of technology and data-driven insights, manufacturing operations now generate vast amounts of data. Manual planners often struggle to process and analyze this data effectively, limiting their ability to make well-informed decisions.

Lack of Real-Time Adaptability: Traditional planning approaches lack the agility needed to respond to dynamic changes in the manufacturing environment. Sudden machine breakdowns, supply chain disruptions, or fluctuating demand can disrupt schedules, and manual planners may struggle to make rapid adjustments.

Inability to Consider Multiple Variables: Production scheduling involves intricate interdependencies between various production tasks, resource availability, and demand patterns. Manual planners may find it challenging to consider all these variables simultaneously, leading to suboptimal schedules.

Limited Scenario Planning: Exploring various "what-if" scenarios to assess the impact of different decisions is crucial in production scheduling. Manual planning often falls short in comprehensively evaluating these scenarios, leaving manufacturers without a full understanding of potential risks and opportunities.

Difficulty in Identifying Patterns and Trends: Manual planners may struggle to discern patterns or trends in historical production data, making it harder to predict demand fluctuations or plan for future resource requirements.

Over-Reliance on Individual Expertise: Traditional planning heavily relies on the knowledge and experience of individual planners. When key personnel leave the organization or retire, there is a risk of losing valuable institutional knowledge, impacting production scheduling capabilities.

As manufacturing becomes increasingly complex and demanding, the limitations of manual planning have become more pronounced, prompting manufacturers to explore innovative alternatives. In the quest for greater efficiency, accuracy, and adaptability, the integration of AI-driven solutions has emerged as a transformative approach to revolutionize production scheduling in the manufacturing domain.

B. Complexities arising from various production factors

In the dynamic world of manufacturing, a multitude of intricate factors interplay to create a web of complexities that significantly impact production scheduling. These complexities arise from the diverse elements that shape the manufacturing process, making the task of scheduling an intricate puzzle that demands intelligent solutions. Some of the key complexities include:

Multi-Stage Production Processes: Many manufacturing operations involve multi-stage processes where products pass through several production steps. Each stage may have different resource requirements and time durations, making it challenging to create a seamless and efficient production schedule.

Resource Constraints: Limited availability of resources, such as raw materials, machinery, and skilled labor, can create bottlenecks in production scheduling. Optimally allocating these resources to various production tasks requires careful consideration of capacity limitations.

Interdependence of Tasks: In manufacturing, tasks are often interconnected, and the delay of one task can trigger a domino effect on subsequent tasks. Addressing these interdependencies is crucial to avoid disruptions and maintain a coherent production schedule.

Product Variability: Manufacturers often produce a range of products with varying specifications and complexities. Scheduling different products while considering their unique characteristics and requirements demands flexibility and adaptability.

Demand Fluctuations: Shifting customer demands and market trends can lead to unpredictable changes in production requirements. Manufacturers must be agile in adjusting production schedules to meet fluctuating demand while avoiding overproduction or stockouts.

Quality and Yield Considerations: Ensuring product quality and yield targets adds another layer of complexity to production scheduling. Scheduling decisions must account for quality control measures and potential rework or scrap rates.

Maintenance and Downtime: Regular maintenance, repairs, and downtime for machinery are inevitable in manufacturing. Properly integrating these planned maintenance activities into the production schedule is crucial to minimize disruptions.

Supply Chain Variability: Manufacturing processes are often dependent on a complex network of suppliers and vendors. Supply chain disruptions, such as delays in raw material deliveries, can create ripple effects on the production schedule.

Seasonal Demands: In certain industries, demand patterns may vary seasonally, requiring manufacturers to adjust production schedules to meet seasonal peaks and lulls.

Regulatory Compliance: Manufacturing companies must adhere to various regulations and standards. Ensuring compliance while scheduling production adds an extra layer of complexity.

Addressing these complexities manually becomes increasingly challenging as manufacturing operations grow in scale and complexity. As a result, manufacturers are turning to AI-driven solutions to intelligently analyze and optimize production schedules, considering these multifaceted factors simultaneously.

AI's ability to process vast amounts of data, identify patterns, and optimize schedules in real-time makes it an invaluable tool in overcoming the complexities that define modern manufacturing production.

C. The impact of uncertainties and bottlenecks

In the realm of manufacturing production scheduling, uncertainties and bottlenecks pose formidable challenges that can disrupt even the most meticulously planned schedules. These factors introduce unpredictability and inefficiency, leading to production delays, increased costs, and decreased overall productivity.

Let's delve into the impact of uncertainties and bottlenecks on production scheduling:

Unpredictable Demand Fluctuations: Changes in customer demands due to market trends, seasonal variations, or unexpected events can create demand uncertainties. Manufacturers may struggle to adjust production schedules rapidly, resulting in either excess inventory or unmet customer demands.

Supply Chain Disruptions: Bottlenecks in the supply chain, such as delays in receiving raw materials or components, can disrupt production schedules. These disruptions may cascade down the production line, leading to idle resources and lost production time.

Machine Breakdowns and Downtime: Equipment failures and unscheduled maintenance can lead to unexpected production downtime. Such occurrences can cause delays in production schedules and compromise the on-time delivery of products.

Labor Shortages or Skill Gaps: Inadequate availability of skilled labor or workforce shortages can impede production capacity and efficiency, creating bottlenecks in the production process.

Quality and Rework Issues: Quality issues, defects, or the need for rework can disrupt production schedules, as time and resources must be redirected to rectify the problems.

Uncertain Lead Times: Variability in lead times for raw materials, components, or finished goods can make it challenging to plan and adhere to production schedules.

Market and Economic Uncertainty: Fluctuations in the economic landscape or changes in market conditions can create uncertainties for manufacturers, impacting their ability to forecast demand accurately.

Regulatory Changes: Changes in regulations or compliance requirements may necessitate adjustments to production processes and schedules, adding uncertainty and complexity.

The cumulative effect of uncertainties and bottlenecks is a significant reduction in production efficiency and effectiveness. Manufacturers may struggle to maintain optimal resource utilization, experience increased operational costs, and face challenges in meeting customer demands promptly.

Addressing uncertainties and bottlenecks is an ongoing challenge in manufacturing, but the integration of AI-driven solutions offers promising possibilities. AI's ability to analyze vast amounts of data, identify patterns, and perform real-time optimizations enables manufacturers to adapt swiftly to uncertainties and avoid bottlenecks.

AI-powered predictive analytics can anticipate demand fluctuations, and prescriptive analytics can suggest optimal solutions to overcome production constraints. By harnessing the power of AI, manufacturers can enhance their ability to navigate uncertainties, optimize production schedules, and ensure a more agile and responsive manufacturing process.

The Emergence of AI in Manufacturing

In the fast-evolving landscape of manufacturing, technological innovations continually reshape the way goods are produced and processes are optimized. Among these groundbreaking advancements, the emergence of Artificial Intelligence (AI) has heralded a new era of possibilities for the manufacturing industry.

As AI technologies mature and demonstrate their transformative potential in various domains, manufacturers are increasingly turning to AI-driven solutions to unlock unprecedented levels of efficiency, productivity, and competitiveness. In this section, we explore the remarkable rise of AI in manufacturing, examining its applications, benefits, and the profound impact it holds on reshaping the future of production processes.

A. Introduction to AI and its applications in manufacturing

Artificial Intelligence (AI) is a cutting-edge technology that empowers machines to mimic human intelligence and perform tasks that traditionally required human cognition. It encompasses a wide range of techniques, including machine learning, natural language processing, computer vision, and robotics, enabling AI systems to learn from data, adapt to new information, and make autonomous decisions.

In the realm of manufacturing, AI has emerged as a transformative force, revolutionizing various aspects of production and supply chain management. Its applications span across the entire manufacturing lifecycle, from product design and development to production scheduling, quality control, and predictive maintenance.

Predictive Maintenance: AI-driven predictive maintenance analyzes real-time data from sensors and equipment to anticipate when machinery might fail. By detecting anomalies and warning signs, manufacturers can schedule maintenance proactively, reducing unplanned downtime and preventing costly breakdowns.

Quality Control and Inspection: AI-powered computer vision systems can detect defects and deviations in products with incredible accuracy. These systems can identify imperfections in real-time, ensuring that only high-quality products reach the market.

Product Design and Optimization: AI algorithms can optimize product designs by exploring various design configurations, simulating performance, and identifying the most efficient and cost-effective solutions.

Supply Chain Optimization: AI can analyze vast amounts of supply chain data to optimize inventory levels, reduce lead times, and enhance supplier management, leading to more streamlined and efficient supply chain operations.

Collaborative Robots (Cobots): AI-driven collaborative robots work alongside human workers, enhancing productivity and safety in manufacturing environments. These robots can handle repetitive tasks and assist in intricate assembly processes.

Advanced Planning and Scheduling (APS): AI-powered APS systems use machine learning algorithms to optimize production schedules, considering various constraints, resource availability, and demand fluctuations.

Demand Forecasting: AI models analyze historical sales data, market trends, and external factors to provide more accurate demand forecasts, enabling manufacturers to align production with actual demand.

Process Optimization: AI continuously analyzes production data to identify inefficiencies and opportunities for improvement. By optimizing processes, manufacturers can increase productivity and reduce waste.

Real-Time Decision Making: AI systems can process vast amounts of data and make real-time decisions, allowing manufacturers to respond quickly to changing conditions and make data-driven decisions.

Energy Efficiency and Sustainability: AI can monitor energy consumption and optimize energy usage in manufacturing processes, promoting sustainable and environmentally friendly practices.

The integration of AI in manufacturing holds the promise of a more agile, efficient, and adaptive industry, where data-driven insights and intelligent automation drive productivity to new heights. As AI technologies continue to advance, their impact on manufacturing processes is bound to be even more profound, shaping the future of manufacturing in ways previously unimaginable.

B. AI-driven advancements in other areas of manufacturing

Beyond production processes and traditional manufacturing functions, Artificial Intelligence (AI) has found remarkable applications in various other areas, transforming the entire manufacturing ecosystem. The integration of AI-driven solutions in these areas brings about unprecedented levels of optimization, cost-efficiency, and innovation.

Let's explore some of the notable AI-driven advancements in other key areas of manufacturing:

Inventory Management: AI-driven inventory management systems use predictive analytics to optimize inventory levels based on historical data, demand forecasts, and market trends. This ensures optimal stock levels, minimizes excess inventory, and reduces holding costs.

Supply Chain Visibility: AI technologies enhance supply chain visibility by tracking and analyzing data throughout the supply chain. This enables manufacturers to identify inefficiencies, anticipate disruptions, and make data-driven decisions to streamline the entire supply chain.

Resource Allocation and Planning: AI algorithms optimize resource allocation, such as workforce scheduling, machine utilization, and material distribution. Manufacturers can achieve better resource utilization, leading to cost savings and improved productivity.

Customer Relationship Management (CRM): AI-powered CRM systems analyze customer data to provide insights into customer preferences, buying behavior, and satisfaction levels. Manufacturers can use this data to tailor products and services to meet customer needs effectively.

R&D and Innovation: AI assists in product development and innovation by analyzing vast amounts of data and simulating various design options. This accelerates the R&D process, enabling faster time-to-market for new products.

Risk Management: AI can predict and mitigate potential risks in manufacturing operations by analyzing historical data and identifying patterns associated with failures or accidents. This proactive approach enhances safety and reduces operational risks.

Energy Management: AI optimizes energy consumption in manufacturing facilities, identifying energy-intensive processes and suggesting energy-saving measures. This leads to reduced energy costs and a more sustainable manufacturing approach.

Waste Reduction and Sustainability: AI-driven systems monitor production processes to detect and address inefficiencies that lead to waste. Manufacturers can implement sustainable practices, contributing to environmental conservation.

Continuous Process Improvement: AI continuously analyzes data from various sources to identify opportunities for process improvement. This data-driven approach fosters a culture of continuous improvement within manufacturing organizations.

Human-Machine Collaboration: AI-driven Cobots (collaborative robots) work alongside human workers, enhancing productivity and safety in manufacturing environments. These Cobots handle repetitive tasks, allowing human workers to focus on more complex activities.

The application of AI in these diverse areas of manufacturing underscores the technology's versatility and its potential to revolutionize the entire manufacturing ecosystem. Manufacturers leveraging AI-driven solutions can gain a competitive edge by optimizing their operations, reducing costs, and delivering products that align precisely with customer demands.

As AI continues to evolve, its impact on manufacturing will undoubtedly expand, shaping a future where data-driven insights and intelligent automation drive the industry towards greater innovation and efficiency.

C. Growing interest in AI for production scheduling

In recent years, there has been a remarkable surge in the interest and adoption of Artificial Intelligence (AI) for production scheduling in the manufacturing industry. As manufacturers face ever-increasing complexities, market dynamics, and customer demands, traditional production scheduling methods have proven inadequate in meeting these challenges.

The shortcomings of manual planning, along with the limitations of conventional scheduling software, have paved the way for AI-driven solutions to revolutionize production scheduling.

Several factors have contributed to the growing interest in AI for production scheduling:

Optimization and Efficiency Demands: In today's hyper-competitive market, manufacturers are under constant pressure to optimize their production processes and enhance efficiency. AI-driven production scheduling offers the promise of more streamlined and optimized schedules, leading to reduced lead times, minimized downtime, and improved resource utilization.

Handling Complexities and Uncertainties: Manufacturing operations are increasingly complex, with multiple production factors, dependencies, and uncertainties to consider. AI's ability to process and analyze large volumes of data enables it to handle these complexities and make data-driven decisions, leading to more robust and agile scheduling.

Real-Time Adaptability: The dynamic nature of manufacturing demands real-time adjustments to production schedules. AI-powered systems can continuously monitor data, detect changes, and quickly adapt schedules to account for unforeseen events, such as machine breakdowns or supply chain disruptions.

Data-Driven Decision Making: AI-driven production scheduling leverages historical and real-time data from various sources, allowing manufacturers to make more informed and data-driven decisions. This leads to improved accuracy and better outcomes in scheduling.

Cost Reduction and Enhanced ROI: Efficient production scheduling through AI optimization can lead to significant cost reductions, from minimized overtime and inventory costs to reduced downtime and waste. These cost-saving benefits drive manufacturers to explore AI solutions.

Scalability and Customization: AI-based production scheduling solutions can be tailored to fit the specific needs and complexities of different manufacturing industries. The scalability of AI systems makes them suitable for small, medium, and large-scale manufacturing operations.

Success Stories and Case Studies: As successful AI implementations in production scheduling continue to emerge, more manufacturers are encouraged to explore and adopt AI-driven solutions. Positive experiences from industry peers validate the potential benefits of AI in this domain.

Advancements in AI Technology: The rapid advancement of AI technology, particularly in machine learning and optimization algorithms, has made AI-driven production scheduling more accessible and feasible for manufacturers.

Competitive Advantage: Early adopters of AI-driven production scheduling gain a competitive edge in the market. Manufacturers recognize that embracing AI technology can help them stay ahead of competitors and meet evolving customer demands effectively.

Industry Collaboration and Research: Collaborations between AI technology providers and manufacturing companies, as well as ongoing research in the field, have contributed to the development and refinement of AI solutions for production scheduling.

As manufacturers witness the transformative potential of AI in production scheduling and experience its tangible benefits, the interest in AI-driven solutions continues to grow. With AI's ability to optimize scheduling, adapt in real-time, and handle complex production environments, it is poised to become a fundamental component of the future of manufacturing scheduling practices.

How AI Improves Production Scheduling

In the ever-evolving landscape of manufacturing, the quest for efficiency and optimization drives manufacturers to explore innovative solutions that transcend traditional paradigms. Enter Artificial Intelligence (AI), a technological marvel that has emerged as a game-changer in the domain of production scheduling.

In this section, we delve into how AI transforms production scheduling, empowering manufacturers to navigate complexities, uncertainties, and real-time demands with unparalleled precision and adaptability. Let us explore the manifold ways in which AI improves production scheduling and reshapes the future of manufacturing operations.

A. Data-driven decision-making

Data-driven decision-making lies at the core of how AI revolutionizes production scheduling in manufacturing. Traditionally, production scheduling relied on manual planning, intuition, and experience, which often led to suboptimal outcomes due to the inability to consider all relevant variables and complexities. AI-powered production scheduling, on the other hand, leverages vast amounts of historical and real-time data to make intelligent and informed decisions.

Data Integration and Analysis: AI systems aggregate data from various sources, including production data, inventory levels, machine performance, demand forecasts, and external factors. By integrating these diverse datasets, AI can create a comprehensive view of the manufacturing environment.

Identification of Patterns and Trends: AI algorithms analyze historical data to identify patterns, trends, and correlations that human planners may overlook. This data analysis enables AI systems to recognize recurring production bottlenecks, predict demand fluctuations, and optimize resource allocation.

Data-Driven Optimization: Armed with extensive datasets, AI algorithms can explore a vast number of possible production schedules and scenarios, considering multiple constraints and objectives. This data-driven optimization process enables AI to identify near-optimal solutions for production schedules.

Real-Time Insights: AI systems continuously monitor real-time data from sensors and other sources, allowing them to respond immediately to changes in the manufacturing environment. This real-time insight empowers manufacturers to make agile and proactive scheduling decisions.

Improved Accuracy and Precision: With AI's ability to process large datasets, production schedules are more accurate and precise, reducing the likelihood of errors and enhancing overall production efficiency.

Anticipating Supply Chain Disruptions: By analyzing data from the entire supply chain, AI can anticipate potential disruptions, such as delays in material deliveries or transportation issues, and suggest alternative scheduling strategies.

Demand Forecasting: AI-driven demand forecasting models utilize historical sales data, market trends, and external factors to predict future demand accurately. This foresight enables manufacturers to align production schedules with actual demand, avoiding overproduction or stockouts.

Identification of Production Constraints: AI can identify production constraints and their impact on overall scheduling. By considering these constraints, AI can ensure that schedules adhere to resource limitations, machine capacities, and other operational constraints.

Data-Driven Insights for Continuous Improvement: Data-driven insights from AI can identify areas for continuous improvement in production processes, allowing manufacturers to refine their operations over time.

Data-driven decision-making through AI is a game-changer for production scheduling, offering manufacturers an unprecedented level of precision, adaptability, and efficiency. By harnessing the power of data and advanced analytics, AI transforms production scheduling from a static and labor-intensive process into an agile, intelligent, and optimized practice that lays the foundation for a more productive and competitive manufacturing future.

B. Predictive and prescriptive analytics for better forecasting

In the realm of production scheduling, predictive and prescriptive analytics powered by AI play a pivotal role in revolutionizing forecasting capabilities. These advanced analytical techniques harness the power of historical and real-time data to provide manufacturers with invaluable insights, enabling them to anticipate future events and make data-driven decisions.

Let's delve into how predictive and prescriptive analytics enhance forecasting in production scheduling:

Predictive Analytics: Anticipating Future Trends

Predictive analytics leverages historical data and machine learning algorithms to identify patterns and trends, enabling manufacturers to forecast future events. In production scheduling, predictive analytics can anticipate demand fluctuations, production bottlenecks, and supply chain disruptions. By analyzing past production data and market trends, predictive models can project future demand patterns, allowing manufacturers to plan production schedules that align with upcoming requirements.

Prescriptive Analytics: Optimizing Decision-Making

Prescriptive analytics takes predictive insights a step further by recommending optimal actions to achieve specific outcomes. In production scheduling, prescriptive analytics can generate production schedules that maximize efficiency, minimize costs, and optimize resource utilization. By considering various constraints, such as machine capacities, labor availability, and inventory levels, prescriptive analytics suggests the best course of action to meet production objectives.

Improved Demand Forecasting

By combining historical sales data, market trends, and external factors, predictive analytics enhances demand forecasting accuracy. This enables manufacturers to make more informed decisions about production volumes, inventory levels, and resource allocation, reducing the risk of overstocking or stockouts.

Risk Mitigation

Predictive analytics can identify potential risks and disruptions in the production process. By analyzing historical data, machine performance metrics, and maintenance records, manufacturers can proactively address equipment failures and other issues that may lead to production delays or breakdowns.

Real-Time Adjustments

The use of real-time data in predictive and prescriptive analytics allows manufacturers to adjust production schedules promptly in response to changing conditions. For instance, sudden changes in demand or supply chain disruptions can be quickly factored into the scheduling process, ensuring optimal resource utilization and meeting customer demands.

Scenario Planning

With prescriptive analytics, manufacturers can perform "what-if" scenario planning to explore different production scenarios and their potential outcomes. This helps in evaluating the impact of various decisions and risks, empowering manufacturers to make proactive and well-informed choices.

Continuous Improvement

By analyzing production data and performance metrics, predictive and prescriptive analytics can identify opportunities for continuous improvement. Manufacturers can refine their production processes over time, leading to increased efficiency and reduced costs.

The integration of predictive and prescriptive analytics in production scheduling elevates forecasting capabilities to new heights. Manufacturers can navigate uncertainties with greater confidence, optimize resource allocation, and respond agilely to dynamic market conditions.

Ultimately, leveraging predictive and prescriptive analytics transforms production scheduling into a proactive and data-driven process, positioning manufacturers for improved efficiency, reduced risks, and enhanced competitiveness in the ever-evolving manufacturing landscape.

C. Machine learning algorithms for optimization

In the realm of production scheduling, machine learning algorithms have emerged as a powerful tool for optimizing and refining scheduling processes. These sophisticated algorithms, a subset of Artificial Intelligence (AI), have the ability to learn from historical data, identify patterns, and make data-driven decisions to create highly efficient production schedules.

Let's explore how machine learning algorithms contribute to optimization in production scheduling:

Automated Pattern Recognition: Machine learning algorithms can analyze vast amounts of historical production data, identifying patterns and trends that may not be apparent to human planners. This automated pattern recognition enables the algorithms to learn from past scheduling decisions and outcomes.

Adaptive Decision-Making: Machine learning algorithms can continuously adapt and improve their performance as they receive new data. As production processes evolve and new data becomes available, the algorithms can adjust their optimization strategies accordingly.

Optimal Resource Allocation: Machine learning algorithms can optimize the allocation of resources, such as raw materials, equipment, and labor, to various production tasks. By considering multiple constraints and objectives, these algorithms can find the most efficient resource allocation for each scheduling scenario.

Dynamic Scheduling: Machine learning algorithms can handle the dynamic nature of manufacturing by making real-time adjustments to production schedules. This adaptability allows manufacturers to respond promptly to changing demands, supply chain disruptions, or machine breakdowns.

Multi-Objective Optimization: Production scheduling often involves multiple conflicting objectives, such as minimizing production costs, reducing lead times, and maximizing resource utilization. Machine learning algorithms can perform multi-objective optimization to find the best compromise among these objectives.

Scenario Analysis: Machine learning algorithms can explore and analyze various "what-if" scenarios to evaluate the impact of different production decisions. Manufacturers can use this capability for contingency planning and risk assessment.

Demand Forecasting: Machine learning algorithms can enhance demand forecasting accuracy by analyzing historical sales data and external factors. Accurate demand forecasts are critical for creating production schedules that align with customer needs.

Continuous Learning and Improvement: As machine learning algorithms receive more data and gain experience, they continuously improve their scheduling capabilities. Manufacturers benefit from increasingly optimized and refined production schedules over time.

Efficient Setup and Changeover Times: Machine learning algorithms can optimize setup and changeover times for production equipment, reducing idle time and improving overall production efficiency.

Scalability: Machine learning algorithms can handle large-scale and complex scheduling problems, making them suitable for a wide range of manufacturing operations.

By leveraging the capabilities of machine learning algorithms, manufacturers can achieve higher levels of production efficiency, reduce costs, and enhance their overall competitiveness. As these algorithms continue to evolve and advance, their role in optimizing production scheduling is poised to become even more crucial, propelling the manufacturing industry into a future of data-driven and intelligent scheduling practices.

D. Real-time monitoring and adjustments

Real-time monitoring and adjustments are integral components of AI-driven production scheduling, enabling manufacturers to respond dynamically to changing conditions and optimize production processes on the fly. By leveraging real-time data and AI algorithms, manufacturers can achieve greater agility, efficiency, and adaptability in their production scheduling.

Let's explore how real-time monitoring and adjustments enhance production scheduling:

Continuous Data Collection: Real-time monitoring involves the continuous collection of data from various sources, including sensors, production equipment, and supply chain systems. This data is fed into AI algorithms to provide up-to-date information about production status and performance.

Immediate Issue Detection: Real-time monitoring allows manufacturers to detect issues and anomalies as they occur. Whether it's a machine breakdown, material shortage, or quality deviation, real-time data provides instant awareness of potential disruptions to the production schedule.

Reduced Downtime: With real-time insights, manufacturers can swiftly address issues that could lead to production downtime. AI algorithms can trigger alerts or automated responses to prevent or minimize disruptions, ensuring continuous production flow.

Dynamic Resource Allocation: Real-time data on resource utilization and availability enables AI algorithms to optimize resource allocation in real-time. This means assigning resources such as machinery and labor to the most critical tasks at any given moment.

Adaptive Scheduling: AI-driven production scheduling can dynamically adjust schedules based on real-time data and changing conditions. Whether it's unexpected customer orders or supply chain delays, the system can quickly recalculate and optimize the production schedule accordingly.

Predictive Maintenance: Real-time monitoring of machine performance data allows AI algorithms to predict when equipment might require maintenance. By proactively scheduling maintenance during periods of lower demand, manufacturers can minimize disruptions to production.

Demand and Market Changes: Real-time data on demand fluctuations and market trends can help manufacturers adjust production schedules to meet changing customer requirements and capitalize on emerging opportunities.

Supply Chain Optimization: Real-time monitoring of supply chain data enables manufacturers to optimize inventory levels, track shipment status, and respond rapidly to supply chain disruptions, ensuring smooth production flow.

Continuous Improvement: Real-time data provides valuable insights for continuous process improvement. Manufacturers can identify areas for optimization and implement changes in real-time to enhance production efficiency.

Agile Decision-Making: Real-time monitoring empowers manufacturers to make agile, data-driven decisions. With access to up-to-date information and AI-generated recommendations, decision-makers can act quickly and confidently.

By incorporating real-time monitoring and adjustments into production scheduling, manufacturers can proactively address challenges and capitalize on opportunities as they arise.

The synergy between real-time data and AI-driven optimization allows for a more adaptive and responsive production process, ultimately leading to enhanced efficiency, reduced lead times, and improved customer satisfaction. As AI technology continues to evolve, real-time monitoring and adjustments will become increasingly integral to the future of manufacturing production scheduling.

AI-Powered Tools for Production Scheduling

In the rapidly advancing landscape of manufacturing, the integration of Artificial Intelligence (AI) has ushered in a new era of innovation and optimization in production scheduling. AI-powered tools have emerged as transformative assets, empowering manufacturers to unlock unprecedented levels of efficiency, agility, and precision in their production processes.

By harnessing the capabilities of AI algorithms, data-driven insights, and real-time adaptability, these tools have revolutionized the way production schedules are planned, executed, and optimized. In this section, we delve into the diverse array of AI-powered tools that are reshaping production scheduling, exploring their applications, benefits, and the immense potential they hold for driving the manufacturing industry towards a more intelligent and productive future.

A. Advanced Planning and Scheduling (APS) systems

Advanced Planning and Scheduling (APS) systems are at the forefront of AI-powered tools revolutionizing production scheduling in the manufacturing industry. These sophisticated software solutions leverage the capabilities of AI algorithms and data analytics to optimize production schedules, resource allocation, and supply chain management.

APS systems enable manufacturers to address the complexities and uncertainties of modern manufacturing environments, leading to more efficient and effective production processes.

Let's explore the key features and benefits of APS systems in production scheduling:

Real-Time Data Integration: APS systems gather data from various sources, such as production machines, sensors, ERP systems, and external data feeds. By integrating real-time data, these systems provide up-to-date insights into the manufacturing environment, facilitating agile decision-making.

Multi-Objective Optimization: APS systems excel at multi-objective optimization, considering multiple constraints and objectives simultaneously. This includes minimizing production costs, reducing lead times, optimizing resource utilization, and meeting customer demand requirements.

Demand Forecasting: APS systems employ AI-driven demand forecasting models to predict future customer demand accurately. With reliable demand forecasts, manufacturers can adjust production schedules to align with market fluctuations.

Resource Management: APS systems optimize the allocation of resources, such as labor, materials, and machinery, to ensure efficient and cost-effective production schedules. They consider resource capacities, skill levels, and availability to minimize idle time and maximize productivity.

Scenario Planning and What-If Analysis: APS systems enable manufacturers to perform scenario planning and what-if analysis, evaluating the impact of various production scenarios and potential disruptions. This helps in contingency planning and risk assessment.

Dynamic Scheduling: APS systems can dynamically adjust production schedules in real-time based on changing conditions, such as machine breakdowns, order changes, or supply chain disruptions. This adaptability ensures optimal resource utilization and on-time delivery.

Improved Customer Service: By aligning production schedules with customer demand and market trends, APS systems enhance customer service levels, reducing lead times and ensuring timely order fulfillment.

Reduced Inventory Costs: By optimizing production schedules and aligning them with demand forecasts, APS systems help manufacturers reduce excess inventory and carrying costs, leading to improved cash flow.

Enhanced Visibility and Collaboration: APS systems provide enhanced visibility across the entire production process, enabling better collaboration among different departments and stakeholders. This transparency fosters effective communication and decision-making.

Continuous Improvement: APS systems continuously learn and adapt from historical data and performance feedback, allowing for continuous improvement in production scheduling and operational efficiency.

The integration of APS systems into production scheduling brings a wealth of benefits, empowering manufacturers to achieve higher levels of productivity, efficiency, and customer satisfaction. As manufacturers embrace the power of AI-driven APS tools, they gain a competitive edge in a fast-paced and dynamic manufacturing landscape, propelling the industry towards a more intelligent and optimized future.

B. Robotics and automation in scheduling

In the realm of production scheduling, robotics and automation have emerged as transformative technologies that work in tandem with AI-driven solutions to optimize manufacturing processes. The integration of robotics and automation in scheduling brings increased efficiency, flexibility, and precision to production operations. Let's explore the role of robotics and automation in production scheduling and the benefits they offer to manufacturers:

Automated Production Tasks: Robotics and automation systems can perform repetitive and labor-intensive production tasks with high accuracy and consistency. By automating such tasks, manufacturers can streamline production processes and reduce manual intervention.

Flexible Production Lines: Automated systems, such as robotic arms and conveyor systems, can be easily reconfigured and adapted to different production needs. This flexibility allows for efficient scheduling of diverse product lines and faster changeovers between production runs.

Just-In-Time (JIT) Manufacturing: Robotics and automation enable JIT manufacturing, where production schedules are aligned with real-time customer demand. JIT scheduling reduces inventory levels, minimizes waste, and improves overall production efficiency.

Optimized Workflows: Automated systems can be synchronized with production schedules, ensuring seamless coordination between different stages of the manufacturing process. This optimization of workflows minimizes idle time and improves overall productivity.

24/7 Production Capability: Automated systems can operate continuously, enabling round-the-clock production. This capability allows manufacturers to meet tight deadlines and respond quickly to fluctuating demand.

Predictable Lead Times: With robotics and automation, production times become more predictable and consistent. This predictability enables better planning and scheduling of downstream processes, such as shipping and delivery.

Quality Assurance and Inspection: Automated systems can perform precise quality control and inspection tasks, ensuring that products meet stringent quality standards. This reduces the likelihood of defects and the need for rework, leading to smoother production schedules.

Collaborative Robots (Cobots): Cobots are robots designed to work alongside human workers. They can handle intricate tasks, freeing human workers from repetitive activities and enabling them to focus on more complex aspects of production.

Real-Time Production Monitoring: Robotics and automation systems provide real-time data on production performance and machine status. This data is valuable for monitoring production progress and making timely adjustments to the schedule.

Risk Mitigation: Automated systems can perform hazardous or dangerous tasks, reducing the risk of workplace accidents and injuries. This enhances safety and minimizes disruptions due to unplanned downtime.

The integration of robotics and automation in production scheduling marks a paradigm shift in manufacturing operations. Manufacturers benefit from increased productivity, reduced production costs, and improved product quality. As these technologies continue to evolve, their seamless integration with AI-powered scheduling solutions holds the promise of a more intelligent, efficient, and optimized manufacturing future.

C. Internet of Things (IoT) integration for data-driven insights

The Internet of Things (IoT) is revolutionizing production scheduling in manufacturing by enabling the seamless integration of physical devices, sensors, and machines with digital technologies. Through IoT integration, manufacturers gain access to a wealth of real-time data and actionable insights, enhancing the data-driven decision-making process in production scheduling.

Let's explore how IoT integration empowers manufacturers with valuable data-driven insights for more efficient production scheduling:

Real-Time Data Collection: IoT devices and sensors installed throughout the production process continuously collect and transmit data. This real-time data includes machine performance metrics, temperature, humidity, energy consumption, and other critical production variables.

Automated Data Monitoring: IoT integration automates data monitoring, eliminating the need for manual data collection and reducing the risk of human error. Real-time data streams provide up-to-the-minute information about production status and resource utilization.

Predictive Maintenance: IoT-enabled sensors can monitor the health of production equipment in real-time, detecting anomalies and potential issues. By analyzing this data, manufacturers can predict when maintenance is needed, preventing costly equipment breakdowns and minimizing downtime.

Quality Control and Defect Detection: IoT devices can monitor product quality at various stages of production. They can detect defects, variations, or deviations from quality standards, allowing for immediate corrective actions and reducing waste.

Supply Chain Visibility: IoT integration extends visibility beyond the manufacturing facility, providing real-time insights into the supply chain. Manufacturers can monitor the movement of raw materials and finished goods, anticipate delays, and adjust production schedules accordingly.

Energy Management: IoT sensors can monitor energy consumption in production processes, providing data for optimizing energy usage and implementing energy-saving measures. This contributes to cost reduction and sustainability efforts.

Demand Sensing: IoT-enabled devices can capture data from point-of-sale systems, e-commerce platforms, and other sources to sense real-time demand fluctuations. This data is valuable for adjusting production schedules to match current demand levels.

Real-Time Tracking of Work in Progress (WIP): IoT integration allows for the real-time tracking of WIP inventory, enabling manufacturers to identify bottlenecks, balance workloads, and optimize production flow.

Data Analytics and AI Integration: IoT data serves as a crucial input for AI-driven analytics and optimization algorithms. By combining IoT-generated data with AI technologies, manufacturers can make more accurate and proactive decisions in production scheduling.

Continuous Improvement: IoT integration facilitates continuous improvement initiatives by providing rich data for performance analysis and process optimization. Manufacturers can identify areas for enhancement and refine production schedules to drive greater efficiency.

The integration of IoT in production scheduling empowers manufacturers with data-driven insights, enabling them to make more informed decisions and respond promptly to changes in the manufacturing environment. As IoT technologies continue to advance, the scope and impact of data-driven insights on production scheduling are expected to expand, paving the way for a more interconnected, intelligent, and efficient manufacturing ecosystem.

Benefits of AI-Driven Production Scheduling

In the dynamic landscape of modern manufacturing, the adoption of AI-driven production scheduling has ushered in a multitude of benefits, revolutionizing the way manufacturers plan, execute, and optimize their production processes. By harnessing the power of Artificial Intelligence (AI) algorithms, data-driven insights, and real-time adaptability, AI-driven production scheduling offers a transformative approach that empowers manufacturers with unparalleled efficiency, agility, and precision.

In this section, we explore the diverse array of benefits that AI brings to production scheduling, ranging from optimized resource allocation and reduced lead times to enhanced productivity and improved customer satisfaction. Let's delve into the manifold advantages of AI-driven production scheduling and its profound impact on reshaping the manufacturing industry for a more intelligent and productive future.

A. Enhanced production efficiency and productivity

One of the most significant benefits of AI-driven production scheduling is the remarkable enhancement of production efficiency and productivity. By leveraging AI algorithms and data-driven insights, manufacturers can optimize production schedules and resource allocation, leading to streamlined operations and increased output. Let's explore the ways in which AI-driven production scheduling contributes to enhanced efficiency and productivity:

- Optimized Resource Allocation: AI algorithms analyze data on machine capacities, labor availability, and material availability to allocate resources optimally. This ensures that each resource is utilized to its full potential, reducing idle time and maximizing productivity.

- Minimized Downtime: AI-driven real-time monitoring and predictive maintenance enable manufacturers to proactively address machine issues and maintenance requirements. By minimizing unplanned downtime, production schedules run more smoothly, and throughput is improved.

- Agile Production Planning: AI's ability to analyze real-time data and adjust schedules in response to changing conditions allows manufacturers to adapt quickly to demand fluctuations and supply chain disruptions. This agility minimizes delays and production bottlenecks.

- Just-In-Time (JIT) Manufacturing: With AI-driven demand forecasting and production scheduling, manufacturers can adopt JIT manufacturing practices. This approach reduces excess inventory, lowers carrying costs, and ensures that products are produced precisely when needed.

- Reduced Lead Times: By optimizing production schedules, manufacturers can significantly reduce lead times, enabling faster order fulfillment and improved customer satisfaction.

- Increased Throughput: AI-driven production scheduling minimizes idle time, reduces setup times, and optimizes production sequences. These improvements lead to increased throughput and higher production capacity.

- Elimination of Manual Errors: AI-powered automation reduces the risk of human errors in production scheduling. This minimizes the need for manual interventions and ensures more accurate and reliable schedules.

- Continuous Process Improvement: AI algorithms continuously analyze production data, identifying areas for improvement and optimization. Manufacturers can implement these insights to enhance overall production efficiency over time.

- Optimal Production Sequencing: AI can identify the most efficient production sequences, taking into account setup times, production times, and resource availability. This optimization ensures smooth production flow and minimizes unnecessary downtime.

- Resource Efficiency: AI-driven production scheduling ensures that resources are allocated in the most efficient manner, reducing waste and unnecessary costs.

The enhanced production efficiency and productivity achieved through AI-driven production scheduling translate to significant cost savings, improved competitiveness, and better utilization of resources. As manufacturers continue to embrace AI technologies, the trajectory of production scheduling is poised to lead the industry into a future of higher performance and increased value generation.

B. Minimization of production downtime and waste

AI-driven production scheduling plays a pivotal role in minimizing production downtime and waste, ushering in a new era of efficiency and cost-effectiveness in manufacturing operations. By leveraging AI algorithms, real-time data, and predictive insights, manufacturers can proactively address potential issues, optimize production schedules, and reduce waste across the production process.

Let's explore how AI-driven production scheduling achieves this significant benefit:

Predictive Maintenance: AI-enabled predictive maintenance systems continuously monitor the health of production equipment using real-time data from sensors. By detecting early signs of wear or potential failures, manufacturers can schedule maintenance activities proactively, minimizing unplanned downtime and costly production stoppages.

Real-Time Production Monitoring: AI-driven production scheduling integrates real-time data from production machines and processes. This allows manufacturers to monitor production progress in real-time and promptly address any deviations or bottlenecks that may lead to downtime.

Dynamic Scheduling and Adaptability: AI algorithms can adjust production schedules in real-time based on changing conditions, such as machine breakdowns or supply chain disruptions. This adaptability ensures that production processes continue efficiently, even in the face of unexpected events.

Optimization of Changeovers: AI-driven scheduling systems optimize changeover times between different product runs or production setups. By reducing changeover times, manufacturers can minimize idle time and increase production throughput.

Efficient Resource Allocation: AI algorithms optimize the allocation of resources, such as raw materials, labor, and machinery, based on demand forecasts and production schedules. This efficient allocation prevents overuse or underutilization of resources, reducing waste.

Demand-Driven Production: AI-driven demand forecasting enables manufacturers to align production schedules with actual customer demand. This prevents overproduction and reduces excess inventory, minimizing waste.

- Error Prevention and Quality Control:

AI-powered quality control systems can identify defects and deviations from quality standards in real-time. By catching errors early in the production process, manufacturers can avoid producing defective or non-compliant products, reducing waste.

- Optimized Inventory Management: AI-driven production scheduling ensures that inventory levels are maintained at optimal levels. This prevents overstocking, expiration of perishable items, and obsolescence of inventory, minimizing waste and associated costs.

- Lean Manufacturing Practices: AI-driven production scheduling aligns with lean manufacturing principles, which aim to eliminate waste and non-value-added activities. By optimizing production schedules and resource utilization, manufacturers can embrace lean practices and achieve greater operational efficiency.

- Continuous Improvement: AI algorithms continuously analyze production data, identifying areas for improvement and optimization. Manufacturers can implement these insights to continuously refine their production processes, reducing waste over time.

The minimization of production downtime and waste through AI-driven production scheduling leads to significant cost savings, improved resource utilization, and a more sustainable manufacturing operation. As AI technologies continue to advance, the ability to reduce downtime and waste will be further enhanced, cementing AI's role as a critical enabler of efficiency and sustainability in the manufacturing industry.

C. Improved resource allocation and utilization

AI-driven production scheduling brings about a transformative improvement in resource allocation and utilization for manufacturers. By harnessing the power of AI algorithms and data-driven insights, manufacturers can optimize the allocation of resources such as labor, materials, machinery, and time, leading to enhanced productivity and cost-efficiency.

Let's explore the ways in which AI-driven production scheduling achieves improved resource allocation and utilization:

Optimal Workforce Planning: AI algorithms analyze production schedules, labor availability, and skill sets to allocate the right workers to specific tasks. This ensures that the workforce is utilized efficiently, reducing labor shortages and idle time.

Dynamic Machine Allocation: AI-driven production scheduling optimizes machine allocation based on production requirements and machine capacities. This prevents overloading or underutilizing machines, maximizing production efficiency.

Real-Time Production Monitoring: AI integration with production processes allows for real-time monitoring of resource usage. Manufacturers can track resource utilization and make immediate adjustments to maintain optimal levels.

Predictive Maintenance and Equipment Optimization: AI-powered predictive maintenance systems anticipate machine breakdowns, enabling timely maintenance. This minimizes downtime and ensures that machines operate at their peak efficiency.

Efficient Inventory Management: AI-driven production scheduling optimizes inventory levels based on demand forecasts and production schedules. This prevents overstocking and minimizes carrying costs, freeing up capital for other investments.

Reduced Changeover Times: AI algorithms optimize changeover times between different product runs or production setups, reducing idle time and increasing the utilization of production equipment.

Demand-Driven Resource Allocation: AI-driven demand forecasting enables manufacturers to align resource allocation with customer demand. This prevents underutilization of resources during periods of low demand and avoids overallocation during peak demand.

Resource Balancing: AI-driven production scheduling ensures a balanced allocation of resources across different production tasks and shifts, maximizing overall resource efficiency.

Scenario Planning: AI algorithms allow manufacturers to perform "what-if" scenarios to evaluate the impact of different resource allocation strategies. This helps in identifying the most efficient resource allocation plan.

Optimized Energy Consumption: AI integration with production processes enables the optimization of energy usage. Manufacturers can adjust production schedules to minimize energy consumption during periods of high electricity costs.

By achieving improved resource allocation and utilization, manufacturers can enhance production efficiency, reduce operating costs, and increase overall profitability. The data-driven insights and real-time adaptability of AI-driven production scheduling empower manufacturers to make smarter resource allocation decisions, ultimately driving greater competitiveness and success in the modern manufacturing landscape.

D. Faster response to changing demands and disruptions

AI-driven production scheduling equips manufacturers with the agility and responsiveness needed to address changing demands and disruptions swiftly. By leveraging real-time data, predictive insights, and adaptive algorithms, AI empowers manufacturers to adjust production schedules in real-time, ensuring a seamless response to dynamic market conditions.

Let's explore how AI-driven production scheduling enables faster response to changing demands and disruptions:

Real-Time Data Integration: AI systems integrate real-time data from sensors, production processes, and supply chain systems. This continuous flow of data provides manufacturers with up-to-the-minute insights into production status and demand fluctuations.

Demand Sensing: AI-powered demand forecasting models analyze real-time sales data, market trends, and external factors to sense changes in customer demand. Manufacturers can quickly adjust production schedules to meet evolving customer needs.

Dynamic Scheduling: AI algorithms can dynamically adjust production schedules based on changing demand or supply chain disruptions. Manufacturers can respond promptly to unexpected events, ensuring timely order fulfillment and reduced lead times.

Scenario Planning and What-If Analysis: AI-driven production scheduling enables manufacturers to perform scenario planning and what-if analysis. They can simulate different production scenarios to evaluate the impact of potential disruptions and make proactive decisions.

Supply Chain Visibility: AI integration with supply chain systems provides manufacturers with real-time visibility into the movement of raw materials and finished goods. This visibility helps in anticipating supply chain disruptions and adjusting production schedules accordingly.

Optimized Inventory Management: By aligning production schedules with demand forecasts, AI-driven production scheduling helps in optimizing inventory levels. Manufacturers can respond more effectively to changes in demand, avoiding overstocking or stockouts.

Proactive Maintenance Planning: AI-powered predictive maintenance systems anticipate equipment failures and maintenance needs. Manufacturers can schedule maintenance proactively during periods of low demand, reducing the risk of production disruptions.

Real-Time Production Monitoring: AI integration with production processes allows manufacturers to monitor production in real-time. Any deviations from the schedule or performance issues can be addressed promptly to maintain production efficiency.

Improved Communication and Collaboration: AI-driven production scheduling enhances communication and collaboration across different departments and teams. This streamlined communication allows for faster decision-making and response to changing demands.

Enhanced Customer Satisfaction: Faster response to changing demands and disruptions enables manufacturers to meet customer requirements promptly. This leads to improved customer satisfaction and loyalty.

The ability to respond rapidly to changing demands and disruptions is a competitive advantage in the manufacturing industry. AI-driven production scheduling empowers manufacturers to be proactive and agile, positioning them for success in a dynamic and unpredictable business landscape. With the aid of AI, manufacturers can navigate uncertainties with greater confidence, ensuring a more resilient and responsive production process.

Overcoming Challenges and Considerations

In the pursuit of embracing AI-driven production scheduling, manufacturers must navigate a set of unique challenges and considerations to unlock its full potential. While the benefits of AI in scheduling are significant, there are practical and strategic factors that demand careful attention.

In this section, we explore the key challenges manufacturers may encounter while implementing AI-driven production scheduling and the crucial considerations to address for a successful integration.

By acknowledging and overcoming these challenges, manufacturers can harness the true transformative power of AI in reshaping their production processes and positioning themselves for a competitive edge in the ever-evolving manufacturing landscape.

A. Integration with existing systems and infrastructure

One of the primary challenges in implementing AI-driven production scheduling is the seamless integration of AI technologies with existing systems and infrastructure. Many manufacturing facilities already have established production processes, supply chain systems, and legacy software solutions. Therefore, integrating AI into the existing ecosystem requires careful planning and consideration. Let's explore the key aspects of overcoming this challenge:

- Data Compatibility: Ensuring that AI algorithms can effectively process and analyze data from existing systems is crucial. This may involve data transformation, standardization, and consolidation to make it compatible with AI models.

- Interoperability: AI-driven production scheduling systems must be interoperable with existing software and equipment. This ensures a smooth exchange of data and information between AI solutions and other production systems.