How do aerospace companies manage the complexity of manufacturing aircraft, navigating global supply chains, and ensuring compliance with stringent regulations? The answer lies in advanced technology solutions like Enterprise Resource Planning (ERP) software, specifically designed for the aerospace industry.

Aerospace ERP software integrates various processes—supply chain management, production planning, maintenance, and regulatory compliance—into one unified system, enabling companies to operate more efficiently and reduce the risk of costly errors.

In the aerospace industry, where precision and compliance are non-negotiable, adopting the right ERP system can make all the difference. These solutions help streamline operations, optimize resource utilization, and provide real-time data to make informed decisions.

Whether managing inventory for aircraft parts, ensuring compliance with FAA or EASA standards, or overseeing complex production processes, aerospace ERP software provides a comprehensive platform to simplify these intricate tasks.

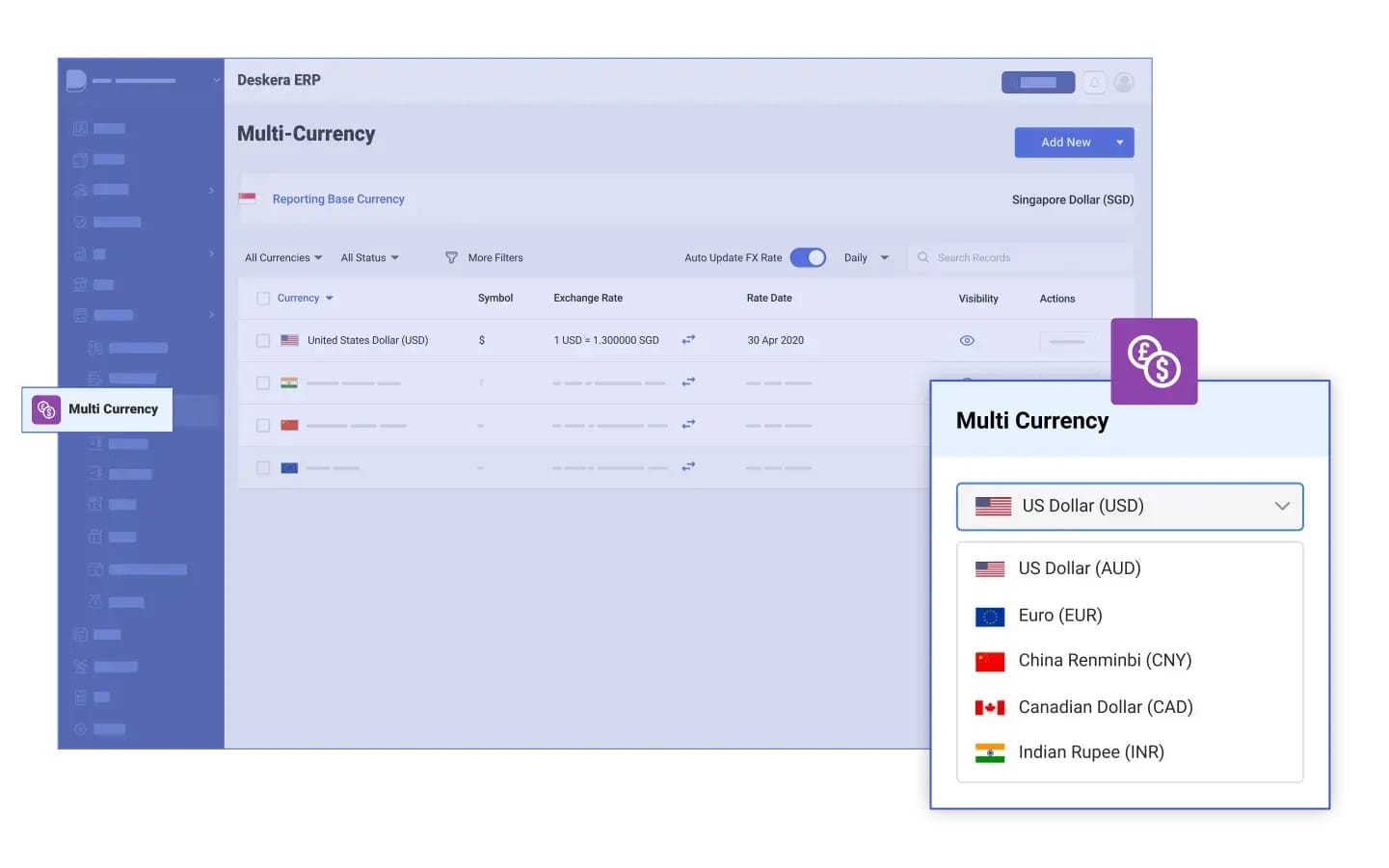

Among the top ERP solutions, Deskera ERP stands out for its ability to address industry-specific needs. Deskera offers cloud-based ERP software that integrates manufacturing, inventory, and financial management into a single platform, making it highly efficient for aerospace companies.

With features like AI-driven demand forecasting, advanced reporting, and mobile accessibility, Deskera empowers businesses to stay competitive and compliant in an increasingly complex landscape.

What is Aerospace ERP Software?

Aerospace ERP software is a specialized form of Enterprise Resource Planning (ERP) designed to meet the unique needs of the aerospace and defense industries. Unlike generic ERP systems, which provide broad functionalities across multiple industries, ERP software for the aerospace industry integrates essential operations such as production management, supply chain coordination, compliance tracking, and quality assurance—all tailored to the highly regulated and complex nature of aerospace.

This type of software helps companies manage everything from aerospace manufacturing to inventory control, project management, and financial planning. By unifying various business processes into a single, streamlined platform, aviation ERP software enables aerospace manufacturers to improve efficiency, reduce operational costs, and ensure compliance with industry standards such as FAA and EASA. It also supports advanced features like maintenance, repair, and overhaul (MRO), which are critical to ensuring the airworthiness of aircraft.

Modern cloud ERP software for aerospace manufacturers offers additional flexibility and scalability. These systems allow real-time data access and integration across global operations, making it easier for businesses to adapt to changing demands and regulations.

Solutions like IFS aerospace and defense ERP software not only enhance operational efficiency but also improve decision-making through real-time insights and analytics, essential for aerospace companies looking to maintain competitiveness in a high-stakes environment.

Key Differences Between General ERP Systems and Aerospace ERP Software

While general ERP systems provide broad functionalities applicable across various industries, aerospace ERP software is specifically designed to address the unique requirements and complexities of the aerospace and defense sectors.

Here are the key differences:

- Regulatory Compliance: One of the most significant distinctions is the level of compliance required in aerospace. ERP software for the aerospace industry is tailored to meet stringent industry regulations like FAA, EASA, and ITAR. This specialized software ensures that all documentation, quality checks, and compliance processes are managed efficiently, unlike general ERP systems, which may not include the same level of regulatory oversight.

- Maintenance, Repair, and Overhaul (MRO): Aerospace ERP systems come with dedicated modules for MRO, which is crucial for maintaining aircraft safety and operability. General ERP solutions may offer maintenance tracking, but they lack the comprehensive MRO capabilities essential for managing the lifecycle of aircraft components.

- Supply Chain Complexity: Aerospace companies deal with a global and highly intricate supply chain that includes managing long lead times for parts and materials. Aerospace manufacturing software is designed to optimize these complex supply chains, offering features like real-time tracking, vendor management, and traceability, which general ERP systems often don’t fully support.

- Project Management and Cost Control: In aerospace, projects are typically large-scale and long-term, often involving multiple contractors and compliance checkpoints. ERP software for the aerospace & defense industry offers advanced project management tools that track progress, costs, and compliance in real-time, helping companies avoid cost overruns—something that general ERP systems may not handle with the same level of granularity.

- Industry-Specific Functionalities: Aerospace and defense ERP software often includes modules for handling specific industry needs such as configuration management, engineering change orders (ECOs), and document control, which general ERP systems lack. Solutions like IFS Aerospace and Defense ERP come equipped with features that address these niche requirements.

These differences highlight the need for aerospace companies to choose aviation ERP software that is designed to handle the industry's specific demands, ensuring compliance, efficiency, and streamlined operations.

Key Features of Aerospace ERP Software

Aerospace ERP software is designed to address the complex needs of the aerospace and defense industries. Its key features set it apart from general ERP systems, making it an indispensable tool for companies in this sector.

Below are the core functionalities of ERP software for aerospace manufacturers:

Regulatory Compliance Management

Compliance is a top priority in the aerospace industry, and aerospace ERP software is built to meet strict standards such as FAA, EASA, ITAR, and AS9100. These systems offer automated tools to track and document compliance throughout the entire supply chain, ensuring adherence to regulatory requirements at all times.

Maintenance, Repair, and Overhaul (MRO)

A vital feature of aviation ERP software is its MRO capabilities, which are essential for managing the lifecycle of aircraft components. The software ensures real-time tracking of maintenance schedules, repair history, and overhaul processes to maximize the uptime of aircraft and minimize operational risks.

Supply Chain and Inventory Management

ERP software for the aerospace & defense industry provides advanced supply chain and inventory management tools that offer real-time visibility into parts availability, lead times, and supplier performance. The system tracks and manages complex supply chains, enabling seamless coordination with global suppliers and reducing the risk of delays.

Project and Cost Management

Aerospace projects often involve intricate, multi-year contracts and require precise cost tracking. Aerospace manufacturing software includes project management features that allow for real-time cost control, resource allocation, and task tracking to ensure that projects stay on time and within budget.

Engineering Change Management

The ability to manage engineering changes efficiently is critical in aerospace. Cloud ERP software for aerospace manufacturers includes tools for tracking engineering change orders (ECOs) and ensuring that all departments are aligned when adjustments are made. This helps minimize disruptions and ensures smooth transitions during production changes.

Quality Assurance and Traceability

Ensuring product quality and maintaining traceability is essential for safety and compliance in aerospace. Aerospace ERP software offers integrated quality control processes, allowing manufacturers to trace parts and materials throughout their lifecycle, ensuring that only compliant products reach the final assembly stage.

Advanced Reporting and Analytics

Aerospace ERP systems offer robust reporting and analytics capabilities, providing real-time insights into production efficiency, supply chain performance, and financial health. These data-driven insights help companies make informed decisions, optimize processes, and maintain compliance.

Scalability and Cloud Integration

Modern cloud ERP software for aerospace manufacturers offers the flexibility to scale as a business grows. Cloud-based systems provide real-time access to data from anywhere, making it easier for global aerospace companies to manage operations across multiple locations and collaborate with suppliers worldwide.

By leveraging these features, aerospace companies can enhance operational efficiency, maintain compliance, and streamline processes, making aerospace ERP software a critical asset for both large enterprises and SMEs.

Benefits of Implementing Aerospace ERP Software

Implementing aerospace ERP software provides a range of strategic benefits for companies operating in the aerospace and defense industries. These advantages go beyond improving day-to-day operations, driving long-term growth, compliance, and innovation.

Here are the key benefits:

Enhanced Regulatory Compliance

Compliance with industry regulations like FAA, EASA, and ITAR is crucial in aerospace. Aerospace and defense ERP software automates the tracking of compliance documentation, audit trails, and quality control processes, reducing the risk of non-compliance and associated penalties. This ensures that companies meet regulatory standards without manual oversight.

Streamlined Operations and Efficiency

ERP software for aerospace manufacturers integrates various business processes—from procurement and inventory management to production and financials—into one system. This seamless integration eliminates data silos, automated workflows, and reduces redundant tasks, thereby boosting overall operational efficiency.

Improved Supply Chain Visibility

Aerospace companies rely on global, complex supply chains. Aerospace ERP software offers real-time visibility into inventory levels, supplier performance, and production timelines. This level of transparency helps companies better manage lead times, reduce bottlenecks, and ensure that materials and parts are available when needed, improving production efficiency.

Cost Control and Financial Management

One of the major benefits of ERP software for the aerospace industry is its ability to provide comprehensive financial insights. By consolidating financial data into a single platform, companies can better track project costs, manage budgets, and forecast future financial needs. This leads to improved decision-making and cost control, especially for large-scale aerospace projects.

Optimized Maintenance, Repair, and Overhaul (MRO)

Aviation ERP software comes with built-in MRO capabilities, helping companies maintain aircraft and components more efficiently. The system tracks repair schedules, maintenance needs, and overhaul histories, ensuring aircraft uptime is maximized and downtime is minimized. This results in greater operational reliability and lower maintenance costs.

Improved Product Quality and Traceability

Quality assurance is vital in aerospace manufacturing. Aerospace ERP software ensures strict quality control processes are in place, from the sourcing of materials to the final product. With advanced traceability features, companies can track components and materials throughout the supply chain, ensuring defects are detected early and compliance is maintained.

Scalability and Flexibility

Cloud-based ERP software for aerospace manufacturers allows companies to scale their operations easily as they grow. Whether expanding production capacity, entering new markets, or managing global operations, cloud ERP provides the flexibility and accessibility needed to meet evolving business demands.

Data-Driven Decision Making

With advanced analytics and real-time reporting, aerospace ERP software offers valuable insights into performance metrics across various departments. Companies can use these insights to make data-driven decisions, optimize resource allocation, and identify opportunities for process improvements, all of which contribute to enhanced business agility and competitiveness.

Better Collaboration Across Departments

A unified ERP system facilitates better communication and collaboration among different departments such as engineering, procurement, finance, and production. This leads to fewer misunderstandings, faster decision-making, and a more cohesive approach to achieving business goals.

Reduced Lead Times

With streamlined supply chain management and real-time inventory tracking, aerospace manufacturing software reduces lead times by optimizing procurement and production schedules. This ensures timely delivery of materials, enabling faster production cycles and improved delivery times for finished goods.

Better Risk Management

ERP software for the aerospace & defense industry helps companies identify, assess, and mitigate risks across their operations. By consolidating data into one platform, companies can better forecast potential disruptions in supply chains, monitor financial risks, and ensure compliance with industry standards. This leads to better decision-making when faced with unexpected challenges.

Improved Customer Satisfaction

Aerospace manufacturers and service providers can use aviation ERP software to deliver better customer experiences by providing accurate delivery timelines, real-time project updates, and reliable after-sales service. The integration of customer management tools helps companies address client needs proactively and ensure high levels of customer satisfaction.

Integration with Advanced Technologies

Modern cloud ERP software for aerospace manufacturers is designed to integrate with emerging technologies such as IoT, AI, and machine learning. This allows companies to adopt predictive maintenance, automate routine tasks, and gain deeper insights through AI-powered analytics, enabling smarter business strategies and operational improvements.

Enhanced Data Security and Compliance

Aerospace companies deal with sensitive data related to national defense and proprietary technology. Aerospace ERP software is equipped with advanced security features, including encryption, user access controls, and multi-factor authentication, to safeguard confidential information. This is critical for meeting government regulations and ensuring data integrity across global operations.

Environmental and Sustainability Initiatives

With a growing focus on sustainability, ERP software for the aerospace industry helps companies track and reduce their environmental impact. The system can monitor energy usage, emissions, and waste throughout the production process, allowing manufacturers to adopt greener practices and meet sustainability goals while staying compliant with environmental regulations.

Vendor and Contractor Management

Managing multiple vendors and contractors is common in aerospace. Aerospace ERP software provides a centralized platform for vendor management, helping companies evaluate supplier performance, manage contracts, and ensure timely deliveries. This leads to better relationships with suppliers and reduced procurement costs.

Effective Resource Planning

By offering real-time insights into resource availability, ERP aviation software helps companies optimize the use of materials, labor, and equipment. This ensures that resources are allocated efficiently across production processes, leading to reduced waste and improved productivity.

Global Collaboration and Compliance Support

As aerospace companies often operate globally, cloud ERP software for aerospace manufacturers allows for seamless collaboration across multiple locations. The software supports multiple currencies, languages, and regional compliance requirements, making it easier for companies to manage global operations without running into regulatory or logistical issues.

Lifecycle Management of Aircraft and Components

Aerospace and defense ERP software includes features that track the entire lifecycle of aircraft and key components, from manufacturing to end-of-life disposal. This ensures better lifecycle management, accurate record-keeping, and timely replacement of parts, which is critical for maintaining safety standards and operational efficiency.

By leveraging these benefits, aerospace companies can improve their operational efficiency, ensure compliance, and gain a competitive edge in the industry. IFS Aerospace and Defense ERP and other industry-specific solutions offer the tools needed to stay ahead in this highly regulated and fast-paced market.

How to Choose the Right Aerospace ERP Software

Selecting the appropriate aerospace ERP software is crucial for enhancing operational efficiency and ensuring compliance in the aerospace and defense industries. With various options available, companies should consider several key factors to ensure they choose a solution that meets their specific needs.

Here’s a guide to help in the selection process:

Assess Industry-Specific Requirements

Begin by identifying the unique needs of your aerospace operations. Look for ERP software for the aerospace industry that offers features such as regulatory compliance management, MRO capabilities, and advanced supply chain management. Ensure that the software is designed to handle the complexities of aerospace manufacturing and can support industry standards.

Scalability and Flexibility

Choose a solution that can grow with your business. Cloud ERP software for aerospace manufacturers often provides the scalability needed to expand operations, add users, and integrate new functionalities as your business evolves. Ensure that the software can accommodate your future growth plans without requiring a complete overhaul.

Integration Capabilities

The ability to integrate with existing systems and third-party applications is essential. Ensure that the aerospace ERP software you choose can seamlessly connect with tools used for CAD, PLM, CRM, and financial systems. This integration facilitates smooth data flow and enhances overall operational efficiency.

User-Friendliness

The software should be intuitive and easy to use for all employees, from management to shop floor staff. A user-friendly interface can reduce training time and increase user adoption rates. Consider requesting a demo or trial period to evaluate the software's usability first hand.

Support for Compliance and Quality Assurance

Given the stringent regulations in aerospace, it is essential that the software provides robust compliance management features. Look for systems that offer tools for tracking quality control processes, documenting compliance efforts, and managing audits. This will help maintain high safety and quality standards.

Robust Reporting and Analytics

Effective decision-making requires access to real-time data and insights. Choose aerospace and defense ERP software that includes advanced reporting and analytics capabilities. This feature will help you monitor key performance indicators, track project progress, and make informed strategic decisions.

Cost and Total Cost of Ownership

Evaluate the total cost of ownership, including initial implementation costs, ongoing subscription fees, and any additional expenses for training, support, or upgrades. While it may be tempting to choose the lowest-cost option, consider the long-term value and return on investment offered by the software.

Vendor Reputation and Support

Research potential vendors to assess their reputation in the aerospace industry. Look for companies with a proven track record in delivering aviation ERP software and excellent customer support. Strong vendor support is essential for troubleshooting issues and ensuring smooth implementation.

Customization Options

The ability to customize the software to fit your specific processes can be a significant advantage. Determine whether the ERP software for aerospace manufacturers allows for customization without extensive programming knowledge, enabling your team to tailor the system to meet your needs.

Future-Proofing

Consider the vendor’s commitment to innovation and staying current with technological advancements. A forward-thinking vendor will continually enhance their cloud ERP software for aerospace manufacturers, ensuring that you have access to the latest features and technologies that can keep your operations competitive.

By carefully evaluating these factors, aerospace companies can select the right aerospace ERP software that not only addresses their current needs but also supports future growth and adaptability in an ever-evolving industry landscape.

Top Aerospace ERP Solutions in the Market

1. Deskera ERP

Overview: Deskera ERP is a comprehensive cloud-based solution designed to streamline various business functions in the aerospace industry. It offers an intuitive interface and integrates seamlessly with other tools to enhance operational efficiency.

Key Features:

- Integrated Financial Management: Comprehensive tools for managing accounts, budgets, and financial reporting tailored for aerospace operations.

- Inventory and Supply Chain Management: Real-time tracking of inventory levels and efficient management of the supply chain, ensuring timely availability of materials.

- Regulatory Compliance Tracking: Tools designed to help businesses comply with industry regulations, including audit trails and documentation management.

- Project Management Capabilities: Streamlined project planning, resource allocation, and tracking to ensure timely completion of aerospace projects.

- Real-Time Analytics and Reporting: Advanced reporting features that provide insights into business performance, helping stakeholders make informed decisions.

- Manufacturing Resource Planning (MRP): Efficient planning and scheduling of manufacturing processes, ensuring optimal resource utilization.

- Quality Management System: Built-in quality control processes to monitor product standards and compliance with aerospace industry regulations.

- Document Management: Centralized storage for critical documents, facilitating easy access and version control.

- Customer Relationship Management (CRM): Tools for managing customer interactions, sales, and service, enhancing customer satisfaction and loyalty.

- Multi-Currency and Multi-Language Support: Features that enable global operations, accommodating diverse markets and clients in the aerospace sector.

- Mobile Accessibility: A mobile-friendly interface that allows users to access ERP functionalities from anywhere, enhancing flexibility and responsiveness.

- AI Assistant David: An intelligent virtual assistant that helps automate routine tasks, provides data insights, and assists users in navigating the ERP system, enhancing productivity and decision-making.

These features make Deskera ERP a robust solution for aerospace companies looking to enhance operational efficiency and maintain compliance in a complex regulatory environment.

2. Oracle NetSuite

Overview: Oracle NetSuite is a leading cloud ERP platform that provides a full suite of business applications tailored for the aerospace and defense sectors. It supports complex financial management and operational workflows.

Key Features:

- Advanced financial management tools

- Supply chain and order management

- Compliance and regulatory reporting

- CRM capabilities for customer management

- Customizable dashboards and analytics

3. Microsoft Dynamics 365

Overview: Microsoft Dynamics 365 offers a flexible and scalable ERP solution designed to meet the needs of aerospace manufacturers. It integrates various business processes, enhancing collaboration and efficiency.

Key Features:

- Robust project management tools

- Advanced analytics and AI capabilities

- Supply chain and inventory management

- Compliance tracking and reporting

- Integration with Microsoft Office products

4. Epicor

Overview: Epicor provides industry-specific ERP solutions tailored to aerospace manufacturers. Its focus on manufacturing and supply chain management makes it a strong contender in the aerospace sector.

Key Features:

- Advanced production scheduling and planning

- Supply chain visibility and management

- Quality assurance and compliance features

- Financial management and reporting tools

- Customizable workflows and dashboards

5. Acumatica

Overview: Acumatica is a cloud ERP platform that offers a comprehensive suite of applications for aerospace businesses. Its user-friendly interface and strong project management capabilities make it a popular choice.

Key Features:

- Flexible financial management solutions

- Project accounting and resource management

- Integrated CRM functionalities

- Inventory management and supply chain support

- Real-time visibility and reporting

6. Infor

Overview: Infor delivers tailored ERP solutions specifically for the aerospace and defense industries. Its focus on industry-specific functionality ensures that manufacturers can meet unique challenges.

Key Features:

- Advanced analytics and business intelligence

- Compliance and quality management

- Supply chain planning and execution

- Production scheduling and planning tools

- User-friendly interface with mobile access

7. Sage X3

Overview: Sage X3 is an ERP solution designed for mid-sized manufacturers, including those in aerospace. It offers robust functionality to manage all aspects of production and compliance.

Key Features:

- Comprehensive inventory and supply chain management

- Project management and cost tracking

- Regulatory compliance and quality assurance

- Financial management and reporting tools

- Customizable workflows to suit business needs

8. SAP Business One

Overview: SAP Business One is a robust ERP platform designed for small to midsize businesses, including those in the aerospace sector. It provides a strong foundation for managing operations, finances, and compliance.

Key Features:

- Integrated financial management tools

- Supply chain and inventory control

- Project management and tracking

- Reporting and analytics capabilities

- Customizable to meet industry-specific requirements

Challenges in Implementing Aerospace ERP Software

Implementing aerospace ERP software can significantly enhance operational efficiency and compliance in the aerospace industry, but it also comes with its own set of challenges.

Understanding these challenges is crucial for successful implementation:

Complex Regulatory Compliance

The aerospace and defense industries are subject to stringent regulations and compliance standards. Ensuring that the ERP system meets all necessary compliance requirements can be a complex process, often requiring specialized features and documentation that must be accurately configured.

Integration with Existing Systems

Aerospace manufacturers often use a variety of legacy systems and software. Integrating new aerospace ERP software with these existing tools can be challenging, leading to potential data silos and disruptions in workflows. Effective planning and technical expertise are essential to facilitate smooth integration.

Customization Needs

Different aerospace companies have unique processes and requirements. Customizing aerospace manufacturing software to meet these specific needs can be time-consuming and costly. Balancing customization with out-of-the-box functionality is a common challenge during implementation.

User Adoption and Training

Employees may be resistant to change, especially if they are accustomed to existing systems. Ensuring user adoption requires comprehensive training and support to help staff understand the new software's benefits and functionalities. Lack of proper training can lead to underutilization of the system.

Data Migration Issues

Transferring data from legacy systems to a new ERP platform can be fraught with challenges. Data quality, accuracy, and completeness must be ensured during the migration process to avoid issues down the line. Inadequate data migration can lead to operational inefficiencies and reporting inaccuracies.

Cost Overruns

Implementing an ERP software for the aerospace industry can be a significant financial investment. Budget overruns can occur due to unforeseen customization needs, extended training periods, or delays in integration. Organizations must plan carefully and allocate sufficient resources to mitigate these risks.

Scalability Concerns

As aerospace companies grow, their needs may evolve. Choosing an ERP solution that can scale with the organization’s growth is vital. However, if the selected software lacks scalability features, it can lead to performance issues and necessitate additional investments in the future.

Vendor Reliability and Support

The success of an ERP implementation often depends on the vendor’s reliability and support. Selecting a vendor that understands the complexities of the aerospace industry and offers robust support services is essential. Poor vendor support can lead to prolonged issues and hinder the overall implementation process.

Change Management

Implementing new ERP software often requires significant changes in business processes. Managing these changes effectively is crucial to minimize disruption. A lack of clear communication and stakeholder involvement can lead to resistance and project delays.

Cybersecurity Risks

As ERP systems store sensitive data, ensuring robust cybersecurity measures is essential. Aerospace companies must address potential vulnerabilities and ensure compliance with data protection regulations to safeguard their information and maintain customer trust.

By understanding these challenges, aerospace companies can better prepare for the implementation of ERP software, ensuring a smoother transition and maximizing the benefits of their new system.

The Future of Aerospace ERP Software

The landscape of aerospace ERP software is rapidly evolving, driven by advancements in technology, changing market demands, and the need for greater operational efficiency.

As the aerospace industry continues to grow and adapt, the future of ERP solutions will likely be shaped by several key trends and innovations:

Cloud-Based Solutions

The shift to cloud-based ERP systems will accelerate, providing aerospace manufacturers with greater flexibility, scalability, and accessibility. Cloud solutions allow for real-time data sharing and collaboration across global teams, enhancing decision-making and operational efficiency.

Artificial Intelligence and Machine Learning

The integration of AI and machine learning technologies will transform aerospace ERP systems. These technologies will enable predictive analytics, automated decision-making, and improved forecasting capabilities. As a result, manufacturers can optimize inventory management, reduce downtime, and enhance quality control.

Internet of Things (IoT) Integration

IoT technology will play a significant role in the future of aerospace ERP software. By connecting machines and equipment to the ERP system, manufacturers can gain real-time insights into operational performance, track asset usage, and implement proactive maintenance strategies. This connectivity will lead to improved efficiency and reduced operational costs.

Enhanced Data Analytics and Reporting

Advanced data analytics tools will become more prevalent in aerospace ERP solutions, allowing manufacturers to derive actionable insights from large volumes of data. Enhanced reporting capabilities will facilitate better decision-making, helping organizations respond quickly to market changes and optimize their operations.

Focus on Sustainability

As the aerospace industry faces increasing pressure to adopt sustainable practices, ERP software will need to incorporate features that support sustainability initiatives. This may include tools for tracking carbon footprints, managing waste, and optimizing resource usage, enabling manufacturers to meet regulatory requirements and corporate social responsibility goals.

Customization and Flexibility

The demand for customizable ERP solutions will grow, allowing aerospace manufacturers to tailor their systems to meet specific operational needs. Future ERP software will likely offer modular designs, enabling companies to select and implement only the features that are most relevant to their business.

Collaboration and Integration

Future aerospace ERP systems will focus on enhancing collaboration both internally and with external partners. Improved integration capabilities will allow for seamless data exchange with suppliers, customers, and other stakeholders, fostering stronger partnerships and streamlined supply chain management.

Cybersecurity Enhancements

As the reliance on digital systems increases, so will the emphasis on cybersecurity within aerospace ERP solutions. Future software will likely incorporate advanced security features to protect sensitive data, ensuring compliance with industry regulations and safeguarding against cyber threats.

User-Centric Design

The user experience will become a central focus in the development of future aerospace ERP software. Intuitive interfaces, mobile accessibility, and customizable dashboards will enhance usability, encouraging employee adoption and maximizing the benefits of the ERP system.

Regulatory Compliance Automation

With the aerospace industry facing complex regulatory requirements, future ERP systems will likely include automated compliance tools. These features will help manufacturers stay compliant with industry standards, reducing the risk of violations and streamlining audit processes.

The future of aerospace ERP software holds significant promise for manufacturers looking to enhance their operational efficiency and competitiveness. By embracing these trends and innovations, aerospace companies can position themselves for success in a rapidly changing industry landscape.

ERP Integration with Aerospace Technologies

The integration of ERP software with advanced aerospace technologies is transforming how manufacturers operate, enhancing efficiency, and driving innovation. As the aerospace industry increasingly relies on technology, the seamless connection between ERP systems and various aerospace technologies is crucial.

Here are several key areas where ERP integration is making a significant impact:

Digital Twins

The use of digital twins—virtual representations of physical assets—enables aerospace manufacturers to simulate and analyze performance in real-time. Integrating ERP systems with digital twin technologies allows for better tracking of production processes, predictive maintenance, and lifecycle management, leading to enhanced operational efficiency.

IoT and Smart Manufacturing

The Internet of Things (IoT) is revolutionizing aerospace manufacturing by connecting machines, tools, and sensors to the ERP system. This integration facilitates real-time data collection on equipment performance, enabling predictive maintenance, optimizing production schedules, and improving supply chain visibility. Smart manufacturing processes are enhanced through automation and data analytics.

Advanced Robotics and Automation

As aerospace manufacturers increasingly adopt robotics for assembly and quality control, integrating ERP systems with robotic technologies becomes essential. This integration allows for real-time monitoring of robotic performance, streamlined workflows, and improved resource allocation, ultimately enhancing productivity and reducing lead times.

3D Printing and Additive Manufacturing

The rise of 3D printing in aerospace production demands seamless integration with ERP software. By connecting ERP systems with additive manufacturing technologies, manufacturers can manage inventory, track materials, and optimize production schedules for custom parts, reducing waste and lead times while increasing design flexibility.

Supply Chain Management Solutions

Integrating ERP with advanced supply chain management technologies enhances visibility and coordination across the supply chain. Real-time data sharing between ERP systems and suppliers helps aerospace manufacturers anticipate demand, manage inventory levels, and streamline logistics, ultimately improving responsiveness to market changes.

Cloud Computing

Cloud-based ERP solutions enable aerospace companies to access critical data and applications from anywhere, enhancing collaboration across global teams. Integration with cloud technologies supports scalability, flexibility, and cost-effectiveness, allowing manufacturers to respond quickly to evolving industry demands.

Data Analytics and Business Intelligence

Integrating ERP systems with advanced data analytics tools provides aerospace manufacturers with actionable insights into their operations. By leveraging business intelligence, companies can analyze performance metrics, identify trends, and make data-driven decisions to enhance operational efficiency and reduce costs.

Quality Management Systems (QMS)

The integration of ERP with quality management systems ensures that aerospace manufacturers maintain compliance with industry standards. This connection enables real-time monitoring of quality metrics, facilitates documentation management, and streamlines audit processes, helping to reduce defects and improve product quality.

Customer Relationship Management (CRM)

Integrating ERP with CRM systems allows aerospace companies to manage customer interactions and sales processes more effectively. This integration provides a holistic view of customer data, improving communication and collaboration across departments, and enhancing customer satisfaction and loyalty.

Compliance Management Tools

The aerospace industry is heavily regulated, making compliance management crucial. Integrating ERP systems with compliance management tools automates regulatory tracking, ensuring that manufacturers meet industry standards and minimizing the risk of violations.

Aerospace ERP Software for SMEs vs. Large Enterprises

The aerospace industry presents unique challenges and opportunities, and the implementation of aerospace ERP software can differ significantly between small and medium-sized enterprises (SMEs) and large enterprises. Understanding these differences is crucial for selecting the right ERP solution to meet specific operational needs and strategic goals.

1. Scope and Complexity of Operations

- SMEs: Aerospace SMEs often operate with limited resources and simpler operational structures. Their ERP software needs to focus on core functionalities that streamline processes, such as inventory management, order processing, and basic compliance tracking. A lightweight, user-friendly ERP solution can help these companies manage their operations without overwhelming them with unnecessary complexity.

- Large Enterprises: In contrast, large aerospace companies face complex, multifaceted operations that span global supply chains, multiple production facilities, and diverse product lines. Their ERP systems must support advanced functionalities such as comprehensive project management, sophisticated supply chain analytics, and detailed regulatory compliance tracking. These systems often require customization to cater to the unique needs of various departments and business units.

2. Customization and Scalability

- SMEs: Aerospace SMEs generally seek ERP solutions that offer out-of-the-box functionality with some customization options. They may prioritize cost-effectiveness and quick implementation, looking for systems that can grow with their business but don’t require extensive customization at the outset.

- Large Enterprises: Large aerospace firms typically require highly customizable ERP solutions to accommodate their complex workflows and diverse business processes. These systems must be scalable to support growth and evolving operational needs, often integrating with existing legacy systems and advanced technologies like IoT and AI.

3. Cost Considerations

- SMEs: Budget constraints are a critical consideration for SMEs. They need cost-effective ERP solutions that provide essential functionalities without incurring high initial investments or ongoing costs. Subscription-based models or cloud ERP options are often appealing as they allow SMEs to manage expenses more effectively.

- Large Enterprises: Large enterprises may have more substantial budgets for ERP implementation but also face higher expectations for return on investment. They often consider the long-term benefits of investing in robust, feature-rich ERP systems that can streamline complex operations, enhance productivity, and improve compliance across multiple departments.

4. Implementation Timeline

- SMEs: The implementation timeline for SMEs is typically shorter, as they may have fewer complexities to manage. A streamlined implementation process allows these companies to quickly adopt the new system and begin realizing benefits.

- Large Enterprises: The implementation process for large enterprises can be lengthy and resource-intensive. It often involves extensive planning, stakeholder engagement, and rigorous change management processes to ensure successful adoption across various departments and locations.

5. User Training and Support

- SMEs: With smaller teams, SMEs may require less extensive training programs but still benefit from intuitive user interfaces and support. Access to training resources and responsive customer support is crucial to facilitate smooth transitions and ongoing usage.

- Large Enterprises: Large organizations usually require comprehensive training programs to accommodate a diverse workforce with varying levels of technical expertise. Dedicated support teams and ongoing training resources are essential to ensure that all employees can effectively utilize the ERP system.

6. Regulatory Compliance

- SMEs: While SMEs must comply with industry regulations, their requirements may be less complex than those faced by larger companies. Basic compliance tracking features in their ERP software may suffice, allowing them to manage documentation and reporting effectively.

- Large Enterprises: Large aerospace companies often navigate a labyrinth of regulatory requirements across multiple jurisdictions. Their ERP systems must include robust compliance management tools to ensure adherence to industry standards and minimize the risk of violations.

Common Pitfalls to Avoid When Implementing Aerospace ERP

Implementing aerospace ERP software can be a transformative step for manufacturers, but it also comes with challenges. Awareness of common pitfalls can help organizations navigate the implementation process more effectively.

Here are some key pitfalls to avoid:

1. Inadequate Needs Assessment

Before selecting an ERP system, it’s crucial to conduct a thorough assessment of organizational needs. Failing to clearly define requirements can lead to choosing a system that doesn’t align with business processes, resulting in wasted resources and poor user adoption. Involve key stakeholders from various departments to identify specific needs and functionalities essential for the aerospace sector.

2. Underestimating the Complexity of Implementation

Implementing an ERP system in the aerospace industry can be complex due to regulatory requirements, intricate supply chains, and diverse operational processes. Underestimating the time and resources needed for implementation can lead to delays and disruptions. Create a detailed project plan that accounts for all phases, including data migration, testing, and user training.

3. Neglecting Change Management

Introducing a new ERP system often requires significant changes in workflows and processes. Failing to address change management can result in resistance from employees and low adoption rates. Develop a comprehensive change management strategy that includes clear communication, training programs, and support to ease the transition and foster buy-in from users.

4. Overlooking Data Migration Challenges

Data migration is a critical phase in ERP implementation, and overlooking this step can lead to inaccuracies and data integrity issues. Ensure that data from legacy systems is cleaned, validated, and mapped correctly to the new ERP system. Conduct thorough testing to identify and rectify any data discrepancies before going live.

5. Ignoring Customization Needs

While many ERP systems offer out-of-the-box functionalities, the unique requirements of the aerospace industry may necessitate customization. Ignoring this need can limit the system’s effectiveness. Engage with the ERP vendor to understand customization options and ensure the software can be tailored to meet specific operational demands.

6. Inadequate Training and Support

Even the best ERP software can fail if users are not properly trained. Inadequate training can lead to confusion, errors, and frustration. Implement a robust training program that caters to different user roles and provides ongoing support. Utilize the ERP vendor’s resources and consider designating internal champions to assist their colleagues.

7. Lack of Continuous Evaluation and Improvement

After implementation, it’s essential to continuously monitor and evaluate the ERP system’s performance. Failing to do so can result in missed opportunities for optimization and improvement. Establish key performance indicators (KPIs) to assess the system’s effectiveness and gather feedback from users to identify areas for enhancement.

8. Choosing the Wrong Vendor

Selecting the right ERP vendor is critical for successful implementation. Rushing into a decision without thoroughly evaluating vendors can lead to poor outcomes. Research vendors with expertise in the aerospace industry, seek customer references, and assess their support and service offerings to ensure a good fit.

9. Neglecting Integration with Existing Systems

Aerospace manufacturers often rely on multiple systems for various functions. Neglecting to plan for integration between the new ERP system and existing software can create silos and limit data visibility. Ensure that the chosen ERP solution can integrate seamlessly with other technologies, such as supply chain management tools, quality management systems, and customer relationship management software.

10. Setting Unrealistic Expectations

ERP implementations take time and effort, and setting unrealistic expectations regarding timelines, costs, and outcomes can lead to disappointment and frustration. Establish clear, achievable goals and communicate them effectively across the organization. Acknowledge that the transition may take time and that there will be a learning curve.

Key Takeaways

- Aerospace ERP software is essential for manufacturers looking to streamline operations, enhance compliance, and drive innovation. Understanding its role is crucial for making informed decisions.

- Aerospace ERP software integrates various business processes, providing a centralized platform for managing operations, improving efficiency, and ensuring regulatory compliance within the aerospace sector.

- Unlike general ERP systems, aerospace-specific ERP solutions are designed to meet the unique regulatory and operational demands of the aerospace industry, offering specialized functionalities that cater to complex supply chains and compliance requirements.

- Essential features of aerospace ERP software include real-time inventory management, compliance tracking, project management, and advanced reporting tools, all tailored to support the intricate needs of aerospace manufacturing.

- Implementing aerospace ERP software leads to significant cost savings, improved compliance, enhanced decision-making capabilities, and increased operational agility, ultimately driving growth and competitiveness.

- Selecting the right ERP solution involves assessing specific organizational needs, evaluating vendor capabilities, considering scalability, and ensuring that the system aligns with industry requirements.

- Leading aerospace ERP solutions, such as Deskera ERP, Oracle NetSuite, and Microsoft Dynamics 365, offer diverse functionalities and customization options to address the unique challenges faced by aerospace manufacturers.

- Common implementation challenges include inadequate needs assessment, underestimating complexity, and neglecting change management. Addressing these issues is crucial for a successful ERP rollout.

- The future of aerospace ERP software will be shaped by advancements in technology, such as AI, IoT, and cloud computing, leading to greater integration, enhanced functionality, and improved operational efficiencies.

- Organizations should be mindful of pitfalls like inadequate training, poor vendor selection, and unrealistic expectations to ensure a smooth implementation process and maximize ROI.

Related Articles