Advancements in sustainable paper manufacturing have become increasingly important in recent years as the negative impact of traditional paper manufacturing practices on the environment has become more evident.

The global market for sustainable packaging solutions, including sustainable paper, is expected to reach $244 billion by 2025, growing at a compound annual growth rate of 6.7% from 2020 to 2025. (Source: MarketsandMarkets)

Sustainable paper manufacturing refers to the production of paper in a way that minimizes the use of natural resources, reduces waste, and promotes environmentally friendly practices throughout the entire production process.

This includes the sourcing of raw materials, energy use, water conservation, and waste reduction. Through innovations in technology and the implementation of sustainable practices, the paper manufacturing industry is beginning to shift towards a more sustainable future.

In this article, we will explore the historical background of paper manufacturing, advancements in sustainable paper manufacturing techniques, case studies of companies implementing sustainable practices, the challenges and limitations of sustainable paper manufacturing, and future prospects for the industry.

- What is Sustainable Paper Manufacturing?

- Importance of Sustainable Paper Manufacturing

- Historical Background of Paper Manufacturing

- Advancements in Sustainable Paper Manufacturing

- Case Studies

- Challenges and Limitations of Sustainable Paper Manufacturing

- Future Prospects of Sustainable Paper Manufacturing

- How can MRP and ERP Systems Aid Sustainability in Paper Manufacturing Industry?

- How can Deskera Help You?

- Key Takeaways

- Related Articles

What is Sustainable Paper Manufacturing?

Sustainable paper manufacturing is the production of paper in a way that minimizes the use of natural resources, reduces waste, and promotes environmentally friendly practices throughout the entire production process. This includes the sourcing of raw materials, energy use, water conservation, and waste reduction.

The goal of sustainable paper manufacturing is to minimize the negative impact of traditional paper manufacturing practices on the environment and promote the efficient use of resources. Sustainable paper manufacturing can involve the use of alternative raw materials, energy-efficient technologies, water conservation methods, waste reduction strategies, recycling, and reuse.

Companies that implement sustainable paper manufacturing practices are committed to reducing their environmental footprint and contributing to a more sustainable future for the paper manufacturing industry.

Importance of Sustainable Paper Manufacturing

Sustainable paper manufacturing is important for several reasons:

- Conservation of natural resources: The traditional paper manufacturing process involves the extraction of vast amounts of natural resources, including trees and water. By implementing sustainable paper manufacturing practices, companies can reduce their reliance on these resources and minimize the environmental impact of their operations. Sustainable paper manufacturing involves the use of alternative raw materials, such as agricultural waste, which can help to conserve natural resources.

- Reduced carbon footprint: The paper manufacturing industry is a significant contributor to greenhouse gas emissions, which are a leading cause of climate change. Sustainable paper manufacturing practices, such as the use of renewable energy sources and the reduction of waste, can help to reduce the industry's carbon footprint and mitigate its impact on the environment.

- Waste reduction: The paper manufacturing process produces a significant amount of waste, including paper sludge, wastewater, and solid waste. Sustainable paper manufacturing practices can help to reduce this waste and promote the efficient use of resources. For example, paper mills can implement closed-loop systems that recycle water and materials, reducing the amount of waste that is produced.

- Consumer demand: Consumers are increasingly concerned about the environmental impact of the products they purchase. Companies that implement sustainable paper manufacturing practices can meet this demand and differentiate themselves in the marketplace.

- Compliance with regulations: Governments around the world are implementing regulations to reduce the environmental impact of industries, including the paper manufacturing industry. Companies that implement sustainable paper manufacturing practices can comply with these regulations and avoid fines and other penalties.

Historical Background of Paper Manufacturing

Paper manufacturing has a long and fascinating history, with the first evidence of paper-making dating back to ancient China around 105 AD. Traditional paper-making techniques involved soaking plant fibers, such as bamboo or mulberry bark, in water to create a pulp that was then dried and pressed into thin sheets.

As paper-making spread throughout the world, various improvements were made to the manufacturing process. In the Middle Ages, European papermakers began using water-powered mills to grind pulp, while in the 19th century, the invention of the Fourdrinier machine allowed for the continuous production of paper on a large scale.

However, the traditional paper-making techniques and the more modern paper-making methods have had a significant negative impact on the environment. For example, traditional paper manufacturing techniques required vast amounts of wood, water, and energy, leading to deforestation, water pollution, and greenhouse gas emissions.

To address these issues, advancements in sustainable paper manufacturing techniques have been made in recent years. These advancements focus on reducing the environmental impact of paper production by promoting the efficient use of resources, reducing waste, and minimizing the use of toxic chemicals in the paper-making process.

A. Traditional Paper Manufacturing Techniques

Traditional paper manufacturing techniques involve several steps, including:

- Harvesting of Raw Materials: Traditional paper manufacturing relies on wood as the primary raw material, which is typically obtained by clear-cutting forests. This process can lead to deforestation, loss of biodiversity, and soil erosion.

- Pulping: The wood is then processed through a mechanical or chemical pulping process, which separates the cellulose fibers from the lignin and other impurities. Chemical pulping methods typically involve the use of toxic chemicals such as chlorine, which can release harmful pollutants into the air and water.

- Bleaching: The pulp is then bleached to remove any remaining impurities and to create a white or bright appearance. This process can also involve the use of toxic chemicals such as chlorine, which can lead to the release of harmful pollutants.

- Papermaking: The pulp is then formed into thin sheets by passing it through a paper making machine, which uses heat and pressure to remove excess water and dry the paper.

Overall, traditional paper manufacturing techniques require significant amounts of natural resources, such as wood and water, and can result in harmful pollutants being released into the air and water. These negative impacts have led to the development of more sustainable paper manufacturing techniques that focus on minimizing waste, reducing the use of toxic chemicals, and promoting the efficient use of resources.

B. Impact of Traditional Paper Manufacturing on the Environment

Traditional paper manufacturing has had a significant negative impact on the environment in several ways, including:

- Deforestation: The primary raw material for paper production is wood, and traditional paper manufacturing methods rely heavily on the clear-cutting of forests. This has resulted in deforestation and loss of biodiversity, as well as the destruction of habitats for many species.

- Water Pollution: Traditional paper manufacturing processes can release harmful chemicals, including chlorine and other bleaching agents, into waterways. This can lead to the contamination of rivers, lakes, and other bodies of water, negatively impacting aquatic ecosystems and posing risks to human health.

- Greenhouse Gas Emissions: Traditional paper manufacturing requires significant amounts of energy, usually sourced from non-renewable fossil fuels such as coal or natural gas. The burning of these fuels releases greenhouse gasses, such as carbon dioxide, into the atmosphere, contributing to climate change.

- Waste Generation: Traditional paper manufacturing can generate significant amounts of waste, including paper scraps, chemicals, and water. This waste can contribute to pollution and pose risks to human health and the environment.

The negative impact of traditional paper manufacturing has led to increased awareness of the need for sustainable paper manufacturing practices.

Advancements in Sustainable Paper Manufacturing

Advancements in sustainable paper manufacturing refer to the development and implementation of new techniques and technologies that aim to minimize the environmental impact of paper production while promoting the efficient use of resources.

These advancements include the use of alternative raw materials, energy-efficient technologies, water conservation methods, waste reduction strategies, recycling, and reuse. The goal of these advancements is to reduce the negative impact of traditional paper manufacturing practices on the environment and promote a more sustainable future for the industry.

Companies that implement sustainable paper manufacturing practices are committed to reducing their environmental footprint and contributing to a more sustainable future.

As the demand for sustainable products grows, advancements in sustainable paper manufacturing will continue to play an essential role in ensuring that paper production is more sustainable and environmentally friendly.

A. Use Of Alternative Raw Materials

The use of alternative raw materials is a crucial aspect of sustainable paper manufacturing. Traditional paper manufacturing relies heavily on wood as the primary raw material, which has led to deforestation and other negative environmental impacts. However, the use of alternative raw materials can help reduce the pressure on forests and promote a more sustainable future for the paper industry.

Some examples of alternative raw materials include:

- Agricultural Residues: Agricultural residues, such as straw, bagasse, and corn husks, can be used as a raw material for paper production. These materials are readily available, and their use in paper production can help reduce waste and promote sustainable agriculture practices.

- Recycled Paper: Recycled paper is an excellent alternative raw material for paper production. The use of recycled paper reduces the demand for virgin pulp, conserves natural resources, and reduces waste. Moreover, recycling paper uses less energy and water than producing new paper from virgin pulp.

- Non-wood Fibers: Non-wood fibers, such as hemp, bamboo, and cotton, can also be used as alternative raw materials for paper production. These materials grow faster than trees, require less water and pesticides, and can be produced sustainably.

Incorporating alternative raw materials into the paper manufacturing process can significantly reduce the environmental impact of paper production. By using renewable and sustainable materials, the paper industry can reduce its reliance on non-renewable resources, conserve natural resources, and reduce waste, making it more sustainable and environmentally friendly.

B. Energy-Efficient Technologies

Energy-efficient technologies are an essential aspect of sustainable paper manufacturing as they help reduce energy consumption and greenhouse gas emissions, thus reducing the environmental impact of paper production. Some of the energy-efficient technologies used in sustainable paper manufacturing include:

- Process Optimization: Process optimization involves analyzing and improving the various stages of paper production to reduce energy consumption and increase efficiency. By optimizing processes, the amount of energy required to produce a given amount of paper can be reduced.

- Co-generation: Co-generation is the process of producing electricity and heat simultaneously. In paper production, co-generation plants are often used to generate steam and electricity from biomass or other renewable energy sources.

- Energy Recovery: Energy recovery systems can capture waste heat from paper production processes and use it to generate electricity or heat other parts of the production process.

- Energy-Efficient Equipment: The use of energy-efficient equipment, such as high-efficiency motors, pumps, and compressors, can significantly reduce the energy required to operate paper production equipment.

By reducing energy consumption and greenhouse gas emissions, these technologies help minimize the environmental impact of paper production, conserve natural resources, and promote a more sustainable future for the industry.

C. Water Conservation Methods

Water conservation methods are an essential aspect of sustainable paper manufacturing as water is a crucial resource in paper production, and the industry can have a significant impact on water resources. Some of the water conservation methods used in sustainable paper manufacturing include:

- Closed-Loop Systems: Closed-loop systems involve recycling and reusing water in paper production processes. By recycling water, the amount of freshwater required in the production process is reduced, and wastewater discharge is minimized.

- Water Treatment: Water treatment systems can help reduce water consumption and protect water quality. By treating wastewater, the water can be reused in the production process, reducing the demand for freshwater.

- Water Reduction Targets: Water reduction targets involve setting specific goals for reducing water consumption in paper production. By setting targets, companies can focus on reducing water consumption and improving their overall water efficiency.

- Water Management Practices: Water management practices involve implementing best practices for water use in paper production, such as reducing water use during cleaning and maintenance, and implementing water-efficient technologies.

By reducing water consumption and wastewater discharge, these methods can help protect water resources, reduce the environmental impact of paper production, and promote a more sustainable future for the industry.

D. Waste Reduction Strategies

Waste reduction strategies are an essential aspect of sustainable paper manufacturing as paper production can generate significant amounts of waste that can have a negative impact on the environment. Some of the waste reduction strategies used in sustainable paper manufacturing include:

- Source Reduction: Source reduction involves minimizing waste generation at the source by reducing raw material use and improving production efficiency. By reducing waste at the source, the amount of waste that needs to be managed is minimized.

- Recycling and Reuse: Recycling and reusing materials can significantly reduce the amount of waste generated in paper production. Paper manufacturers can recycle paper waste, including offcuts and trimmings, and reuse it in the production process.

- Composting: Composting involves converting organic waste into nutrient-rich soil. Paper manufacturers can compost organic waste generated in the production process, such as wood chips and bark, to reduce waste and produce a useful product.

- Landfill Diversion: Landfill diversion strategies aim to minimize the amount of waste that goes to landfill by diverting waste to recycling, reuse, and composting facilities. By diverting waste from landfill, paper manufacturers can reduce the environmental impact of waste disposal and promote a more sustainable future.

E. Recycling and Reuse

Recycling and reuse are critical components of sustainable paper manufacturing as they help reduce waste and conserve natural resources. By recycling and reusing materials, paper manufacturers can minimize the environmental impact of paper production and promote a more sustainable future for the industry.

Recycling paper waste is an effective way to reduce the environmental impact of paper production. The process involves collecting used paper and converting it into new paper products. Recycling paper saves natural resources, reduces landfill space, and conserves energy.

The process of recycling paper involves cleaning the used paper, removing ink and other contaminants, and processing it into new paper products. The recycled paper can be used to produce a wide range of products, including newspapers, magazines, and packaging materials.

Reusing materials is another effective way to promote sustainable paper manufacturing. Paper manufacturers can reuse materials, such as offcuts and trimmings, in the production process. By reusing these materials, paper manufacturers can reduce waste and conserve natural resources. Additionally, reusing materials can also help reduce production costs, making sustainable paper manufacturing more economically feasible.

Case Studies

The case studies on advancements in sustainable paper manufacturing highlight the importance of implementing eco-friendly practices in the industry, such as using alternative raw materials, adopting energy-efficient technologies, conserving water, and reducing waste, to reduce the environmental impact of paper production and promote a more sustainable future for the industry.

A. Example 1: Cascades Inc.

Cascades Inc. is a Canadian-based company that specializes in sustainable paper manufacturing. They have implemented several eco-friendly practices in their production process, such as using recycled fibers and producing 100% recycled paper products. Cascades Inc. also uses energy-efficient technologies, such as cogeneration, to reduce energy consumption and greenhouse gas emissions. Additionally, they have implemented water conservation methods, such as closed-loop systems, to minimize water consumption and reduce wastewater discharge. Cascades Inc. also focuses on waste reduction strategies, such as source reduction and landfill diversion, to minimize the amount of waste generated in the production process.

The case study on Cascades Inc. demonstrates how sustainable paper manufacturing practices can be successfully implemented in the industry. By prioritizing eco-friendly practices and investing in sustainable technologies, Cascades Inc. has been able to reduce the environmental impact of their production process and promote a more sustainable future for the industry. The success of Cascades Inc. serves as an example for other paper manufacturers to follow in implementing sustainable practices in their production processes.

B. Example 2: UPM

UPM is a Finnish-based company that specializes in sustainable paper manufacturing. They have implemented several eco-friendly practices in their production process, such as using alternative raw materials, such as straw, and adopting energy-efficient technologies, such as combined heat and power (CHP) plants. UPM also focuses on water conservation methods, such as closed-loop systems, to minimize water consumption and reduce wastewater discharge. Additionally, they have implemented waste reduction strategies, such as recycling and reusing waste, to minimize the amount of waste generated in the production process.

The case study on UPM demonstrates how sustainable paper manufacturing practices can be successfully implemented on a large scale. By investing in sustainable technologies and prioritizing eco-friendly practices, UPM has been able to reduce the environmental impact of their production process and promote a more sustainable future for the industry. The success of UPM serves as an example for other paper manufacturers to follow in implementing sustainable practices in their production processes.

C. Example 3: Domtar Corporation

Domtar Corporation is a North American-based company that specializes in sustainable paper manufacturing. They have implemented several eco-friendly practices in their production process, such as using certified sustainable wood fibers and adopting energy-efficient technologies, such as combined heat and power (CHP) plants.

Domtar Corporation also focuses on water conservation methods, such as closed-loop systems and water recycling, to minimize water consumption and reduce wastewater discharge. Additionally, they have implemented waste reduction strategies, such as recycling and reusing waste, to minimize the amount of waste generated in the production process.

The case study on Domtar Corporation demonstrates how sustainable paper manufacturing practices can be successfully implemented in a large-scale industrial setting. By prioritizing eco-friendly practices and investing in sustainable technologies, Domtar Corporation has been able to reduce the environmental impact of their production process and promote a more sustainable future for the industry.

The success of Domtar Corporation serves as an example for other paper manufacturers to follow in implementing sustainable practices in their production processes.

Challenges and Limitations of Sustainable Paper Manufacturing

The challenges and limitations of sustainable paper manufacturing highlight the need for continued innovation and investment in eco-friendly practices and technologies to address the environmental impact of the industry.

Despite progress in implementing sustainable practices, challenges such as high costs of sustainable materials and technologies, limited availability of alternative raw materials, and difficulties in achieving circularity in the production process pose significant obstacles to achieving a fully sustainable paper manufacturing industry.

Understanding and addressing these challenges is crucial for promoting a more sustainable future for the industry.

A. Cost

Cost is a major challenge and limitation of sustainable paper manufacturing. Implementing eco-friendly practices and technologies often require significant investments, which can be a barrier for smaller paper manufacturers or those with limited financial resources.

For example, using alternative raw materials such as agricultural residues or non-wood fibers can be more expensive than traditional wood pulp. Similarly, adopting energy-efficient technologies or installing closed-loop water systems can require significant capital investments.

The high cost of sustainable materials and technologies can also result in higher prices for sustainable paper products, which can reduce consumer demand and competitiveness. This can be particularly challenging in a market where many consumers prioritize cost over sustainability.

To address the challenge of cost, paper manufacturers can explore alternative financing models, such as partnerships with investors or government funding. Additionally, advancements in technology and increased demand for sustainable products can drive down costs over time, making sustainable practices and products more accessible to a wider range of manufacturers and consumers.

B. Resistance to Change

Resistance to change is another challenge and limitation of sustainable paper manufacturing. Adopting sustainable practices and technologies often requires significant changes to the production process, which can be met with resistance from employees, suppliers, and other stakeholders who may be hesitant to make changes to their established practices.

Resistance to change can manifest in several ways, such as lack of buy-in from management or employees, limited awareness or understanding of sustainable practices, or concerns about the cost or feasibility of implementing sustainable practices. This resistance can lead to delays in implementing sustainable practices or a lack of commitment to sustainable initiatives.

To address resistance to change, paper manufacturers can focus on communication and education to build support for sustainable practices among employees and other stakeholders. Additionally, involving stakeholders in the decision-making process and providing incentives or rewards for adopting sustainable practices can help to build momentum and overcome resistance.

Ultimately, it is important to emphasize the benefits of sustainable practices, such as cost savings, increased efficiency, and positive environmental impact, to help stakeholders see the value in making changes to the production process.

C. Consumer Demand

Consumer demand is a significant challenge and limitation of sustainable paper manufacturing. While there is a growing demand for sustainable products, many consumers prioritize cost and convenience over sustainability. This can make it difficult for paper manufacturers to justify the higher cost of implementing sustainable practices or producing sustainable products, which can limit their ability to make the necessary changes.

Additionally, consumers may not be fully aware of the environmental impact of traditional paper manufacturing practices, which can reduce demand for sustainable paper products. This lack of awareness can be compounded by a lack of transparency in the supply chain, which can make it difficult for consumers to identify and purchase sustainable products.

To address the challenge of consumer demand, paper manufacturers can focus on improving transparency and education around sustainable practices and products. This can involve providing information on product labels, partnering with retailers to promote sustainable products, and leveraging social media and other channels to raise awareness of the environmental impact of traditional paper manufacturing practices.

Additionally, focusing on the unique benefits of sustainable paper products, such as their positive impact on the environment and their durability and quality, can help to build demand and encourage consumers to prioritize sustainability when making purchasing decisions.

D. Government Regulations

Government regulations can be both a challenge and a driver of sustainable paper manufacturing. Regulations can impose strict environmental standards and requirements on paper manufacturers, which can increase the cost of production and limit their ability to operate in certain areas.

However, regulations can also create incentives for manufacturers to adopt sustainable practices and technologies and can help to level the playing field for sustainable products by setting minimum standards for environmental performance.

The challenge with government regulations is that they can vary widely by region and can be subject to change, which can create uncertainty for paper manufacturers. Additionally, regulations may not always be strictly enforced or may be difficult to enforce, which can reduce their effectiveness in promoting sustainable practices.

To address the challenge of government regulations, paper manufacturers can work with regulators to better understand the requirements and opportunities for sustainable production. Manufacturers can also take a proactive approach by advocating for stronger regulations and investing in sustainable practices and technologies to exceed minimum standards.

Additionally, engaging with stakeholders, such as non-governmental organizations and communities, can help to build support for sustainable practices and demonstrate a commitment to environmental responsibility.

Future Prospects of Sustainable Paper Manufacturing

Future prospects of sustainable paper manufacturing are promising, as advancements in technology and increasing consumer awareness and demand for eco-friendly products are driving paper manufacturers to adopt sustainable practices and innovate towards a more environmentally-friendly future.

A. Innovations and Emerging Technologies

Innovations and emerging technologies are key drivers of the future prospects of sustainable paper manufacturing. Advancements in technology are making it possible for paper manufacturers to adopt more sustainable practices and improve their environmental performance.

For example, the use of renewable energy sources, such as biomass and solar power, is becoming increasingly common in paper manufacturing facilities. Additionally, advancements in water treatment and recycling technologies are allowing paper manufacturers to reduce their water consumption and improve their wastewater management practices.

Another area of innovation is the development of new materials and processes that reduce the environmental impact of paper production. For example, some manufacturers are experimenting with using agricultural waste, such as straw and sugarcane bagasse, as a raw material for paper production. Others are exploring the use of biodegradable or compostable materials for paper products.

Digitalization and automation are also emerging as important drivers of sustainable paper manufacturing. By using data analytics and machine learning, paper manufacturers can optimize their production processes, reduce waste, and improve their environmental performance.

B. Potential Impact on the Industry and Environment

The potential impact of innovations and emerging technologies in sustainable paper manufacturing can be significant for both the industry and the environment.

In terms of the industry, these advancements can help paper manufacturers improve their efficiency and competitiveness, reduce costs, and increase profitability. Adopting sustainable practices and technologies can also help companies meet the growing demand for eco-friendly products and demonstrate a commitment to environmental responsibility, which can enhance their brand image and reputation.

From an environmental perspective, the impact of sustainable paper manufacturing can be substantial. By reducing water consumption, energy use, and greenhouse gas emissions, sustainable practices and technologies can help mitigate the environmental impact of paper production. The use of renewable materials and the development of biodegradable or compostable products can also reduce waste and minimize the use of non-renewable resources.

Additionally, sustainable paper manufacturing can have positive impacts on local communities by reducing air and water pollution, protecting wildlife habitats, and promoting sustainable forestry practices.

However, it is important to note that the potential impact of innovations and emerging technologies will depend on the level of adoption by the industry, as well as the effectiveness of regulations and policies to promote sustainable practices. Without sufficient adoption and enforcement, the potential benefits of sustainable paper manufacturing may not be fully realized.

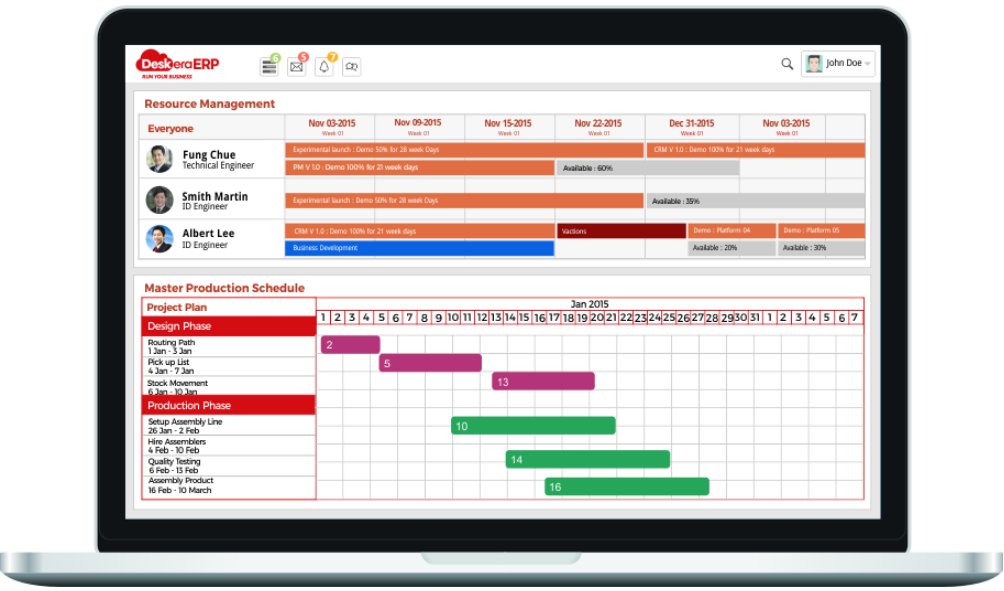

How can MRP and ERP Systems Aid Sustainability in Paper Manufacturing Industry?

MRP (Material Requirements Planning) and ERP (Enterprise Resource Planning) systems can aid sustainability in the paper manufacturing industry in several ways.

First, these systems can help paper manufacturers optimize their production processes and reduce waste. By providing real-time data on inventory levels, production schedules, and supply chain logistics, MRP and ERP systems can enable companies to make more informed decisions about resource utilization, reduce the need for excess inventory, and minimize material waste.

Second, MRP and ERP systems can help paper manufacturers track their environmental performance and identify opportunities for improvement. These systems can be used to monitor energy and water consumption, greenhouse gas emissions, and other environmental indicators. By analyzing this data, companies can identify areas where they can reduce their environmental impact and develop sustainability goals and targets.

Third, MRP and ERP systems can facilitate the use of sustainable materials and suppliers. By providing visibility into the entire supply chain, these systems can enable companies to identify and work with suppliers who prioritize sustainability, use renewable materials, and engage in responsible forestry practices.

Finally, MRP and ERP systems can enable paper manufacturers to comply with regulations and sustainability standards. By automating compliance processes and providing real-time data on environmental performance, these systems can help companies meet regulatory requirements and achieve certification under sustainability standards, such as the Forest Stewardship Council (FSC) and the Sustainable Forestry Initiative (SFI).

Overall, MRP and ERP systems can aid sustainability in the paper manufacturing industry by enabling companies to optimize their production processes, reduce waste, track their environmental performance, use sustainable materials and suppliers, and comply with regulations and sustainability standards.

How can Deskera Help You?

Deskera ERP and MRP systems help you to keep your business units organized. The system's primary functions are as follows:

- Keep track of your raw materials and final items inventories

- Control production schedules and routings

- Keep a bill of materials

- Produce thorough reports

- Make your own dashboards

Deskera's integrated financial planning tools enable investors to better plan and track their investments. It can assist investors in making faster and more accurate decisions.

Deskera Books allows you to better manage your accounts and finances. Maintain good accounting practices by automating tasks like billing, invoicing, and payment processing.

Deskera CRM is a powerful solution that manages your sales and helps you close deals quickly. It not only enables you to perform critical tasks like lead generation via email, but it also gives you a comprehensive view of your sales funnel.

Deskera People is a straightforward tool for centralizing your human resource management functions.

Key Takeaways

- Sustainable paper manufacturing is an important way to reduce the environmental impact of the paper industry, which is one of the largest consumers of natural resources and contributors to greenhouse gas emissions.

- The use of recycled paper fibers and sustainable wood sources are key ways to improve the sustainability of paper manufacturing. Many companies are also exploring alternative fiber sources, such as agricultural waste, to reduce the need for virgin wood.

- Advanced manufacturing technologies, such as water-saving measures, energy-efficient equipment, and closed-loop systems, can significantly reduce the environmental impact of paper manufacturing while also improving efficiency and profitability.

- Digitalization and automation are also playing a key role in sustainable paper manufacturing, allowing companies to optimize production processes and reduce waste.

- Collaboration between industry, government, and non-governmental organizations is essential for driving sustainable paper manufacturing practices and improving the sustainability of the paper industry as a whole.

- Sustainable paper manufacturing not only benefits the environment but can also improve a company's reputation and market competitiveness, as consumers increasingly demand sustainable products.

Related Articles