With 47% of ERP software buyers comprising manufacturing companies, they stand as the largest procurers in the realm of enterprise software. This statistic underscores the pivotal role that manufacturing software systems play in the manufacturing landscape.

A deeper dive into the survey reveals that the primary impetus behind the adoption of ERP systems within manufacturing entities is the pursuit of enhanced functionality.

In this context, manufacturing ERP emerges not merely as a software solution but as a strategic imperative, offering a pathway to operational excellence and competitive advantage.

Within the intricate tapestry of modern industry, efficiency is paramount, and manufacturing ERP serves as a linchpin in achieving this goal. Manufacturing ERP serves as a centralized system for overseeing all facets of facility operations and procedures, spanning from production to payroll management.

This comprehensive software solution offers unparalleled visibility, coordination, and control over diverse business processes, culminating in heightened operational efficiency.

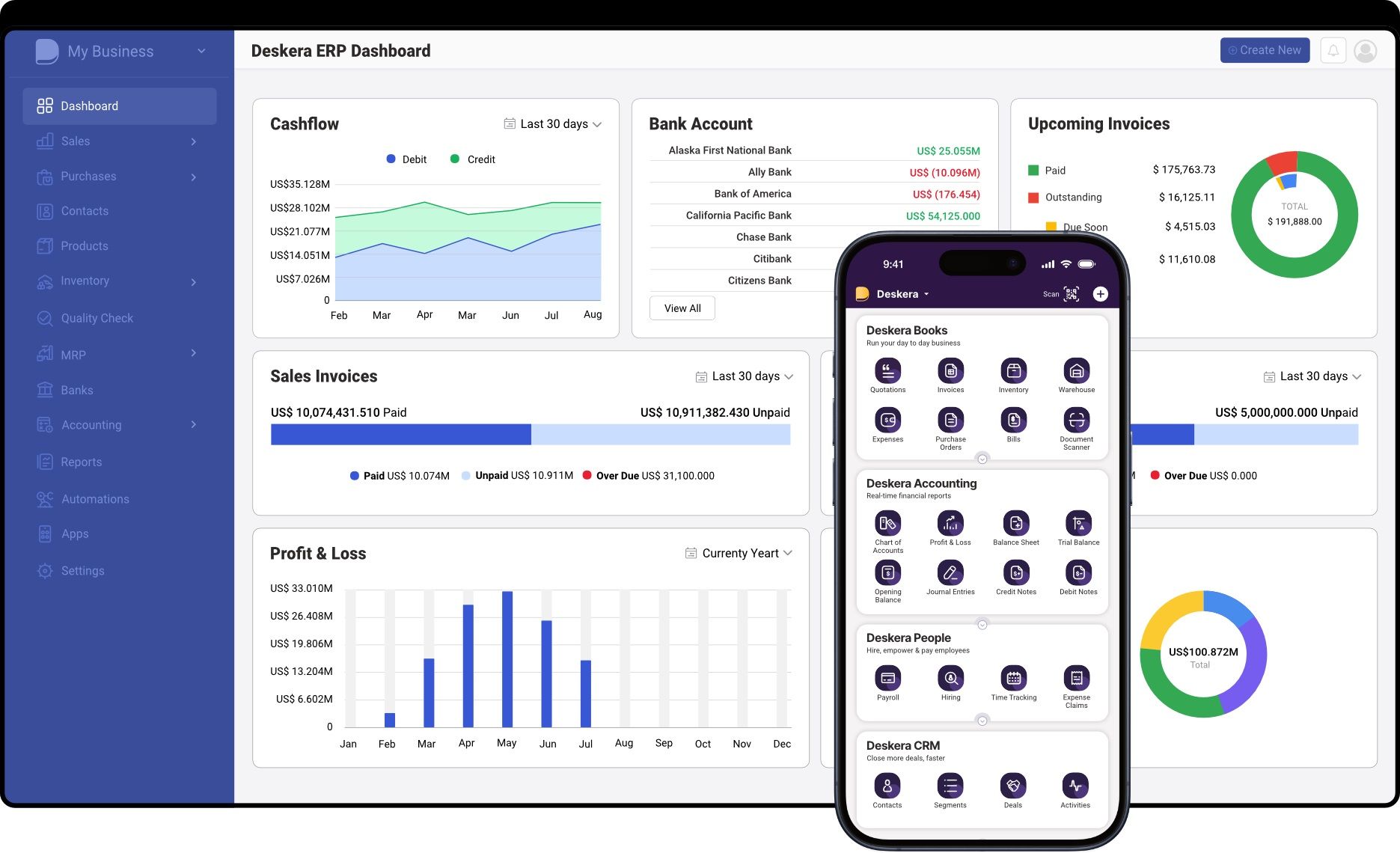

Additionally, platforms like Deskera Manufacturing ERP further augment these capabilities, providing tailored solutions to meet the unique needs of manufacturing enterprises.

What is an ERP System in Manufacturing?

Manufacturing ERP (Enterprise Resource Planning) software stands at the forefront of technological advancements, revolutionizing the operational landscape of manufacturing industries worldwide.

With its comprehensive suite of tools and functionalities, it offers a centralized platform to orchestrate and optimize various aspects of manufacturing operations.

Let's delve deeper into what makes manufacturing ERP software indispensable for modern manufacturing enterprises.

Key Components of Manufacturing ERP Software

- Production Planning and Scheduling: This feature enables manufacturers to efficiently plan and schedule production activities, ensuring optimal utilization of resources and timely delivery of products.

- Inventory Management: Manufacturing ERP software provides robust inventory management capabilities, allowing businesses to track and manage inventory levels, streamline procurement processes, and minimize stockouts or overstock situations.

- Supply Chain Coordination: With integrated supply chain management modules, ERP software enables seamless coordination with suppliers, distributors, and other stakeholders, facilitating smooth material procurement, logistics, and order fulfillment.

- Quality Control and Assurance: Manufacturing ERP systems include tools for monitoring and maintaining quality standards throughout the production process. This may involve implementing quality checkpoints, conducting inspections, and analyzing data to identify and rectify issues promptly.

- Financial Management: From budgeting and cost estimation to invoicing and financial reporting, ERP software offers robust financial management capabilities tailored to the specific needs of manufacturing businesses. It helps ensure transparency, accuracy, and compliance with financial regulations.

- Human Resources Management: ERP solutions include modules for managing workforce-related functions such as payroll processing, employee scheduling, performance evaluation, and training tracking. This streamlines HR processes and enhances employee productivity and satisfaction.

- Shop Floor Control: Manufacturing ERP software provides real-time visibility into shop floor activities, allowing supervisors to monitor production progress, track work orders, and allocate resources effectively.

- Equipment Maintenance and Asset Management: ERP systems help optimize equipment maintenance schedules, track asset utilization, and manage maintenance tasks to minimize downtime and maximize operational efficiency.

- Mobile Accessibility: Mobile accessibility is essential for manufacturing ERP, enabling users to access crucial data and functionalities anytime, anywhere, via their mobile devices. This capability fosters real-time monitoring and informed decision-making, enhancing flexibility and productivity throughout operations.

Manufacturing ERP software represents a holistic solution for addressing the complex operational challenges faced by modern manufacturing enterprises.

By integrating and automating key business processes, it empowers organizations to enhance efficiency, reduce costs, improve decision-making, and maintain a competitive edge in today's dynamic marketplace.

As manufacturing industries continue to evolve, the role of ERP software in driving innovation and success is more critical than ever.

What is the Difference Between Standard ERP and Manufacturing ERP?

When considering ERP solutions, it's essential to understand the distinction between standard ERP and manufacturing ERP software.

While both serve as comprehensive systems for resource planning and management, manufacturing ERP is specifically tailored to meet the unique needs and challenges of manufacturing processes.

Differences Between Standard ERP and Manufacturing ERP

- Scope and Focus: Standard ERP systems offer broad functionality across various industries while manufacturing ERP software is designed specifically to address the intricacies of manufacturing processes. This specialized focus enables manufacturing ERP to provide features and tools tailored to the unique requirements of manufacturing businesses.

- Industry-Specific Functionality: Manufacturing ERP solutions include industry-specific features such as production planning, shop floor control, bill of materials management, and quality control. These functionalities are essential for optimizing manufacturing operations and ensuring compliance with industry standards.

- Shop Floor Control: Unlike standard ERP systems, manufacturing ERP software offers robust shop floor control capabilities, allowing manufacturers to monitor and manage production activities in real time. This functionality is critical for maintaining efficient production workflows and meeting production targets.

- Supply Chain Integration: Manufacturing ERP solutions often include advanced supply chain management features tailored to the needs of manufacturing businesses. These features enable seamless integration with suppliers, distributors, and other stakeholders, facilitating efficient procurement, logistics, and inventory management.

- Resource Optimization: Manufacturing ERP software prioritizes resource optimization by providing tools for efficient inventory management, production scheduling, and resource allocation. These capabilities help manufacturers minimize waste, reduce costs, and maximize operational efficiency.

- Cloud-Based Deployment: While both standard ERP and manufacturing ERP solutions may offer cloud-based deployment options, manufacturing ERP software is specifically optimized for cloud-based environments. This ensures scalability, flexibility, and accessibility, allowing manufacturing businesses to adapt to changing market conditions and scale their operations as needed.

Challenges in the Manufacturing Industry

In the manufacturing industry, several challenges underscore the importance of automating manufacturing processes using ERP solutions:

- Complexity of Operations: Manufacturing involves intricate processes, from production planning to supply chain management, which can be challenging to manage manually. Automating these processes streamlines operations and reduces the risk of errors.

- Complex Supply Chains: Manufacturing companies often deal with intricate supply chains involving multiple suppliers, distributors, and logistics partners. Implementing manufacturing ERP software helps streamline supply chain management, optimize procurement processes, and enhance coordination with stakeholders.

- Supply Chain Disruptions: Disruptions in the supply chain, such as raw material shortages or transportation delays, can disrupt production schedules and impact profitability. Automation enables better supply chain visibility and collaboration, reducing the risk of disruptions and improving resilience.

- Inventory Management: Effective inventory management is critical for manufacturing companies to balance supply and demand, minimize stockouts, and reduce carrying costs. ERP solutions for manufacturing offer robust inventory management functionalities, enabling real-time visibility into inventory levels, automated reorder points, and efficient stock tracking.

- Production Efficiency: Maximizing production efficiency is a constant challenge in the manufacturing industry. ERP manufacturing software helps optimize production processes, streamline workflows, and minimize downtime through features such as production planning, scheduling, and shop floor control.

- Quality Control: Maintaining product quality and consistency is essential for customer satisfaction and brand reputation. Manufacturing ERP solutions include quality control modules to enforce quality standards, track defects, and ensure compliance with regulatory requirements, thereby mitigating quality-related risks.

- Compliance Requirements: Manufacturing companies must adhere to various regulatory standards and compliance requirements, such as environmental regulations, safety standards, and industry certifications. ERP for manufacturing provides tools to manage compliance documentation, track regulatory changes, and ensure adherence to regulatory requirements.

- Data Management: Manufacturing operations generate vast amounts of data, including production data, inventory data, and quality control data. Cloud-based ERP solutions for manufacturing offer centralized data management capabilities, enabling secure storage, seamless data integration, and real-time data access from anywhere, ensuring data accuracy and integrity.

- Increasing Competition: Globalization has intensified competition in the manufacturing sector, prompting companies to seek ways to enhance efficiency and reduce costs. Automation helps manufacturers remain competitive by improving productivity and reducing lead times.

- Fluctuating Demand: Manufacturers often face unpredictable shifts in demand, making it challenging to adjust production levels accordingly. Automated systems enable agile production planning and responsive manufacturing, allowing companies to adapt quickly to changes in demand.

In conclusion, automating manufacturing processes using manufacturing ERP software addresses key challenges in the manufacturing industry, including complex supply chains, inventory management, production efficiency, quality control, compliance requirements, and data management.

By leveraging ERP solutions for manufacturing, companies can streamline operations, optimize resources, and maintain a competitive edge in today's dynamic manufacturing landscape.

Advantages of Implementing Manufacturing ERP

Implementing manufacturing ERP software offers numerous advantages for companies in the manufacturing sector. These ERP solutions for manufacturing are tailored to streamline and optimize various manufacturing processes while enhancing resource planning and management.

In this section of the article, we'll explore the key benefits of utilizing ERP for manufacturing, including how cloud-based solutions are transforming the industry.

- Improved Efficiency and Productivity: Manufacturing ERP software automates repetitive tasks, streamlines workflows, and provides real-time insights into operations, leading to increased efficiency and productivity.

- Enhanced Resource Planning: ERP solutions for manufacturing enable better resource planning by accurately forecasting demand, optimizing inventory levels, and scheduling production activities to minimize bottlenecks and downtime.

- Cost Reduction: By eliminating waste, reducing inventory holding costs, and optimizing production processes, ERP for manufacturing helps companies cut costs and improve profitability.

- Better Decision-Making: Manufacturing ERP software provides executives and managers with access to comprehensive data and analytics, empowering them to make informed decisions quickly and effectively.

- Increased Visibility and Control: With cloud-based ERP manufacturing software, companies gain greater visibility and control over their entire manufacturing operations, from the shop floor to the supply chain.

- Compliance and Regulation Adherence: ERP systems help manufacturing companies stay compliant with industry regulations and standards by enforcing process controls, tracking quality metrics, and ensuring traceability.

- Scalability and Flexibility: Cloud-based manufacturing ERP solutions offer scalability and flexibility, allowing companies to adapt to changing market conditions, expand operations, and integrate new technologies seamlessly.

- Enhanced Operational Visibility: Manufacturing ERP serves as a centralized repository, providing comprehensive insights into every facet of the production process. This accessibility fosters coordination, collaboration, and communication across departments, driving efficiency and innovation.

- Improved Interdepartmental Communication: By breaking down silos and promoting transparency, ERP systems facilitate seamless communication between different departments. This breakdown of barriers enhances collaboration, minimizes redundancies, and maximizes opportunities for cross-functional synergy.

- Centralized Data Management and Analysis: From machine sensors to quality assurance metrics, manufacturing ERP software enables the collection and analysis of vast amounts of data. This data-driven approach empowers organizations to make informed decisions in critical areas such as maintenance, procurement, and supply chain management.

- Facilitated Design and Engineering Collaboration: Manufacturing ERP systems facilitate seamless collaboration between design and engineering teams, resulting in the development of higher-quality products and reduced defects during production. This fosters quality assurance and cost control throughout the manufacturing process.

- Integration of Financial Management and Material Requirements Planning (MRP): ERP for manufacturing seamlessly integrates financial management and MRP modules, enabling organizations to effectively track resources and materials while maintaining financial oversight. This integration streamlines operations and ensures resource optimization.

In conclusion, implementing manufacturing ERP software offers a multitude of benefits for companies looking to streamline their operations, optimize resource utilization, and stay competitive in today's fast-paced manufacturing landscape.

With the advent of cloud-based ERP solutions for manufacturing, companies can leverage advanced technology to drive efficiency, innovation, and growth.

When is a Manufacturing Company Ready for ERP?

Determining when a manufacturing company is ready for ERP software is crucial for maximizing the benefits of such a solution.

Here are some key indicators that suggest a manufacturing company is ready to implement ERP:

- Business Growth: As a manufacturing company experiences growth in production volume, customer base, and market reach, the complexity of managing manufacturing processes increases. Implementing manufacturing ERP software becomes essential to streamline operations, enhance efficiency, and support continued growth.

- Operational Challenges: Manufacturing companies facing operational challenges such as inventory inaccuracies, production delays, inefficient resource utilization, and lack of visibility into processes may benefit from ERP solutions for manufacturing. These systems provide tools to address these challenges and optimize manufacturing processes.

- Manual Processes: If a manufacturing company relies heavily on manual processes, spreadsheets, and disparate systems to manage production, inventory, and other critical functions, it may be time to consider implementing ERP for manufacturing. Automation provided by ERP software improves accuracy, reduces errors, and saves time.

- Lack of Integration: When different departments within a manufacturing company operate in silos, with limited communication and collaboration between them, integration issues arise. Manufacturing ERP software facilitates seamless integration of processes across departments, improving coordination and efficiency.

- Compliance Requirements: Manufacturing companies operating in regulated industries must adhere to strict compliance standards and quality control measures. ERP manufacturing software helps ensure compliance by enforcing standardized processes, tracking regulatory requirements, and maintaining audit trails.

- Scalability Needs: A manufacturing company planning to expand its operations, introduce new product lines, or enter new markets requires scalable solutions to support growth. Cloud-based manufacturing ERP software offers scalability, flexibility, and accessibility, making it an ideal choice for companies with expansion plans.

- Data-Driven Decision-Making: Manufacturing companies seeking to make data-driven decisions and gain actionable insights into their operations can benefit from ERP solutions. Manufacturing ERP software collects, analyzes, and presents data in real time, enabling informed decision-making and strategic planning.

What are the Different Types of ERP Implementation?

When it comes to implementing manufacturing ERP software, there are several different approaches that companies can take based on their specific needs and requirements.

Here are the different types of ERP implementation:

- On-Premises Implementation: This traditional approach involves installing and hosting the ERP software on the company's own servers and infrastructure. The entire system is managed and maintained in-house by the company's IT team. On-premises implementation offers full control over the ERP system but requires significant upfront investment in hardware, software, and IT resources.

- Cloud-Based Implementation: Cloud-based ERP solutions for manufacturing are hosted and managed by third-party providers in remote data centers. The software is accessed over the internet, and companies pay a subscription fee for usage. Cloud-based implementation offers scalability, flexibility, and accessibility, making it an attractive option for manufacturing companies of all sizes.

- Hybrid Implementation: Hybrid implementation combines elements of both on-premises and cloud-based ERP solutions. Companies may choose to host certain components of the ERP system on-premises for greater control and security while utilizing cloud-based services for other functions such as data storage, backup, and disaster recovery.

- Big Bang Implementation: In a big bang implementation, the entire ERP system is deployed across all departments and functions of the organization simultaneously. This approach requires thorough planning and coordination but allows for a rapid transition to the new system. Big bang implementation can be disruptive but offers the benefit of quickly realizing the benefits of the ERP software.

- Phased Implementation: Phased implementation involves rolling out the ERP system in stages, starting with a single department or function and gradually expanding to other areas over time. This approach allows companies to manage the implementation process more gradually, minimizing disruptions and risks. Phased implementation is often preferred for large-scale ERP projects or companies with complex operations.

- Modular Implementation: Modular implementation involves implementing specific modules or functionalities of the ERP system independently, rather than deploying the entire system at once. Companies can prioritize the implementation of modules based on their immediate needs and gradually add additional modules as required. Modular implementation offers flexibility and allows for a more tailored approach to ERP deployment.

- Customized Implementation: Some manufacturing companies may opt for a customized implementation approach, where the ERP software is tailored to meet their unique business processes and requirements. This may involve customizing existing ERP modules or developing new functionalities from scratch. Customized implementation offers the highest level of flexibility but can be more time-consuming and costly.

By selecting the right implementation strategy based on their specific needs and goals, companies can successfully deploy manufacturing ERP software and optimize their manufacturing processes.

What are Deskera’s Manufacturing ERP Features?

Deskera Manufacturing ERP offers a comprehensive suite of features designed to streamline manufacturing operations and enhance efficiency.

Some key features include:

- Production Planning and Scheduling: Deskera Manufacturing ERP enables efficient planning and scheduling of production activities, optimizing resource utilization and minimizing production downtime.

- Inventory Management: The software provides robust inventory management capabilities, allowing users to track and manage inventory levels, monitor stock movements, and streamline procurement processes.

- Shop Floor Control: Deskera Manufacturing ERP offers advanced shop floor control functionalities, providing real-time visibility into production activities, tracking work orders, and optimizing production workflows.

- Quality Control: The system includes tools for monitoring and maintaining quality standards throughout the production process, facilitating inspections, and ensuring compliance with quality regulations.

- Supply Chain Management: Deskera Manufacturing ERP integrates supply chain management functionalities, enabling seamless coordination with suppliers, distributors, and other stakeholders to optimize procurement and logistics processes.

- Financial Management: The software includes financial management modules for budgeting, cost estimation, invoicing, and financial reporting, ensuring transparency and compliance with financial regulations.

- Reporting and Analytics: Deskera Manufacturing ERP offers robust reporting and analytics capabilities, providing insights into key performance metrics, production trends, and operational efficiency.

- Mobile Accessibility: Deskera Manufacturing ERP prioritizes mobile accessibility, empowering users to access critical data and functionalities on the go. Whether on the factory floor or in the boardroom, Deskera's mobile app ensures seamless connectivity, real-time monitoring, and quick decision-making, enhancing agility and productivity across manufacturing operations.

- Cloud-Based: Deskera Manufacturing ERP is built on a cloud-based platform, offering unparalleled flexibility and scalability to manufacturing businesses. By leveraging cloud technology, Deskera enables easy access to data from anywhere, at any time, while minimizing infrastructure costs and ensuring seamless updates and upgrades. This cloud-based approach enhances collaboration, accelerates deployment, and future-proofs manufacturing operations in an ever-evolving digital landscape.

- AI-Assistant - ‘David’: Unlock the power of Deskera's AI assistant to effortlessly access critical financial data, gain valuable inventory insights, and receive intelligent forecasts anytime, anywhere. Seamlessly create transactions and master the use of Deskera ERP with the guidance of your AI companion, simplifying complex tasks and driving smarter decision-making within your manufacturing operations.

Overall, Deskera Manufacturing ERP empowers manufacturing companies to streamline operations, improve productivity, and maintain a competitive edge in the market.

Key Takeaways

Manufacturing ERP software serves as a comprehensive solution to automate and optimize manufacturing processes, driving efficiency, agility, and competitiveness within manufacturing organizations.

The advantages of implementing manufacturing ERP are:

- Improved Efficiency and Productivity

- Enhanced Resource Planning

- Cost Reduction

- Better Decision-Making

- Increased Visibility and Control

- Compliance and Regulation Adherence

- Scalability and Flexibility

- Enhanced Operational Visibility

- Improved Interdepartmental Communication

- Centralized Data Management and Analysis

- Facilitated Design and Engineering Collaboration

- Integration of Financial Management and Material Requirements Planning (MRP)

The key indicators to look out for which suggest that your manufacturing company is ready for ERP are:

- Business Growth

- Operational Challenges

- Manual Processes

- Lack of Integration

- Compliance Requirements

- Scalability Needs

- Data-Driven Decision-Making

The features of Deskera’s manufacturing ERP that will help you are:

- Production Planning and Scheduling

- Inventory Management

- Shop Floor Control

- Quality Control

- Supply Chain Management

- Financial Management

- Reporting and Analytics

- Mobile Accessibility

- Cloud-Based

- AI-Assistant- ‘David’

As manufacturing industries continue to evolve, the adoption of ERP solutions becomes increasingly crucial for staying ahead of the curve, maintaining sustainability, and achieving long-term success.

Related Articles